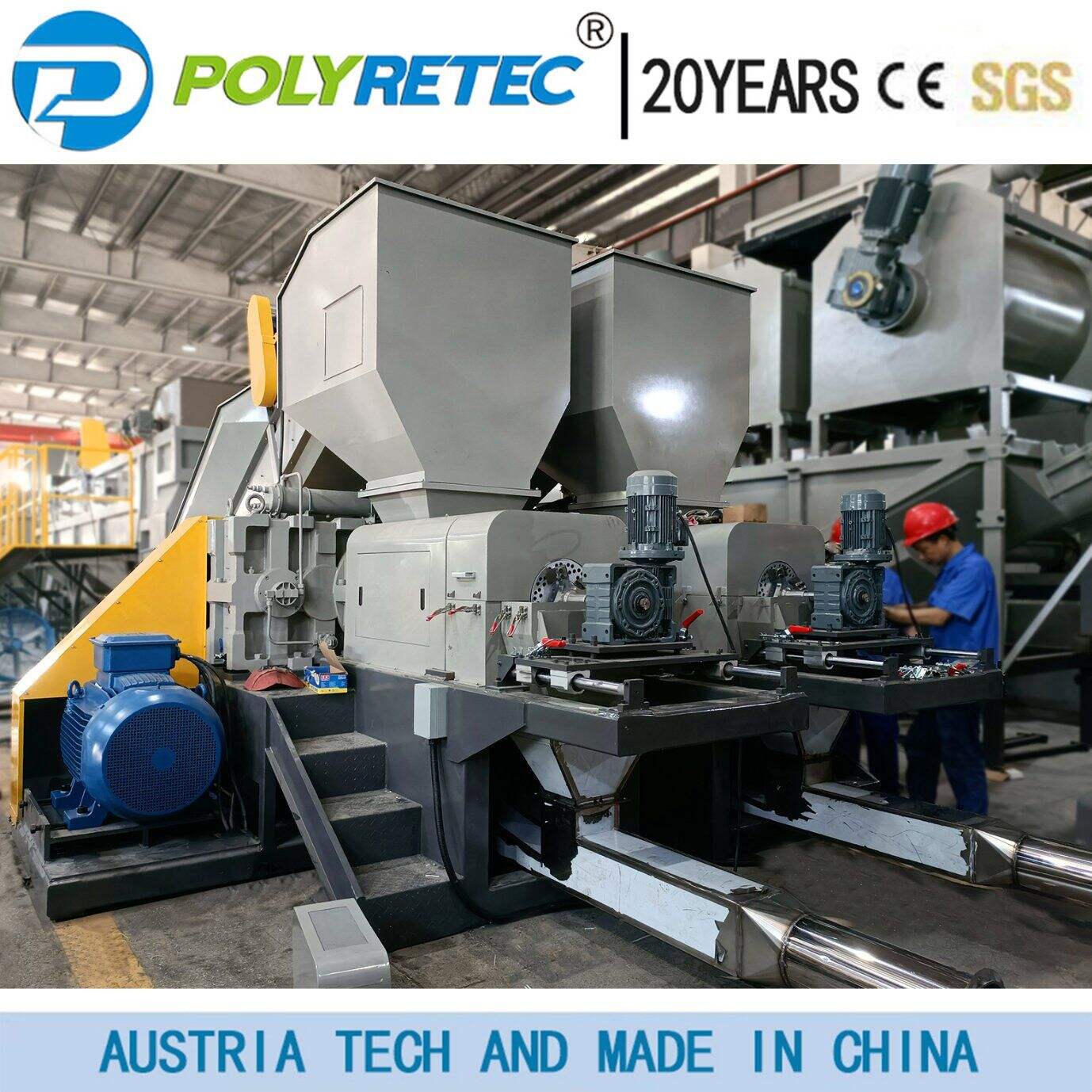

plastic recycling extruder machine

The plastic recycling extruder machine represents a cornerstone technology in modern recycling operations, designed to transform waste plastic materials into valuable recycled products. This sophisticated equipment operates through a systematic process that begins with the feeding of plastic waste into a hopper, where it undergoes careful sorting and cleaning. The material then moves through a heating chamber where it's melted at precisely controlled temperatures, typically ranging from 130 to 350 degrees Celsius, depending on the plastic type. The molten plastic is then forced through an extruder screw, which homogenizes the material and removes impurities. The machine's advanced control system maintains consistent temperature and pressure throughout the process, ensuring high-quality output. The extruded material can be shaped into pellets, sheets, or profiles depending on the die attachment used. Modern plastic recycling extruders are equipped with smart monitoring systems that track performance metrics and material flow in real-time, allowing for immediate adjustments to optimize production. These machines can process various plastic types, including PE, PP, PS, and ABS, making them versatile solutions for recycling facilities, manufacturing plants, and waste management operations.