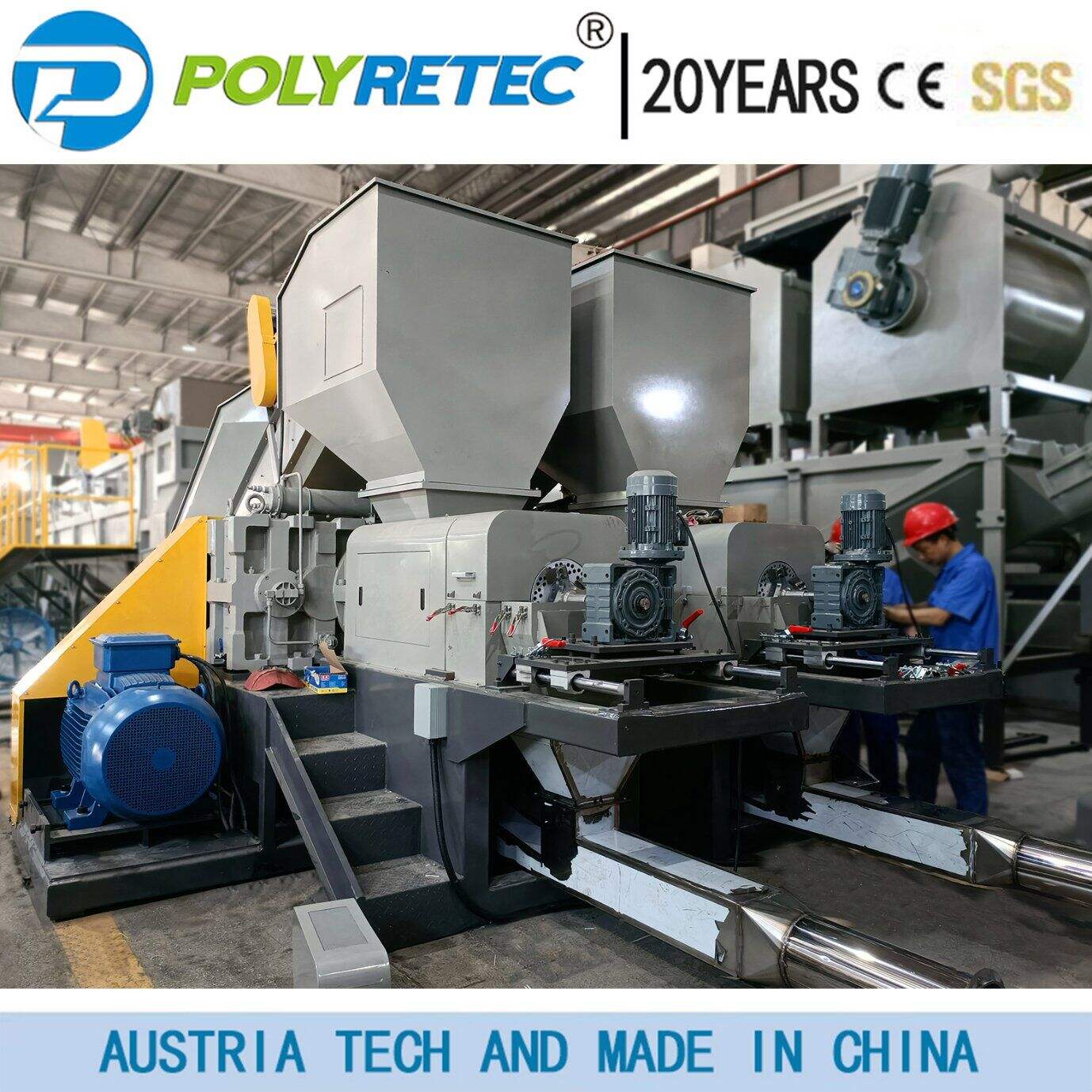

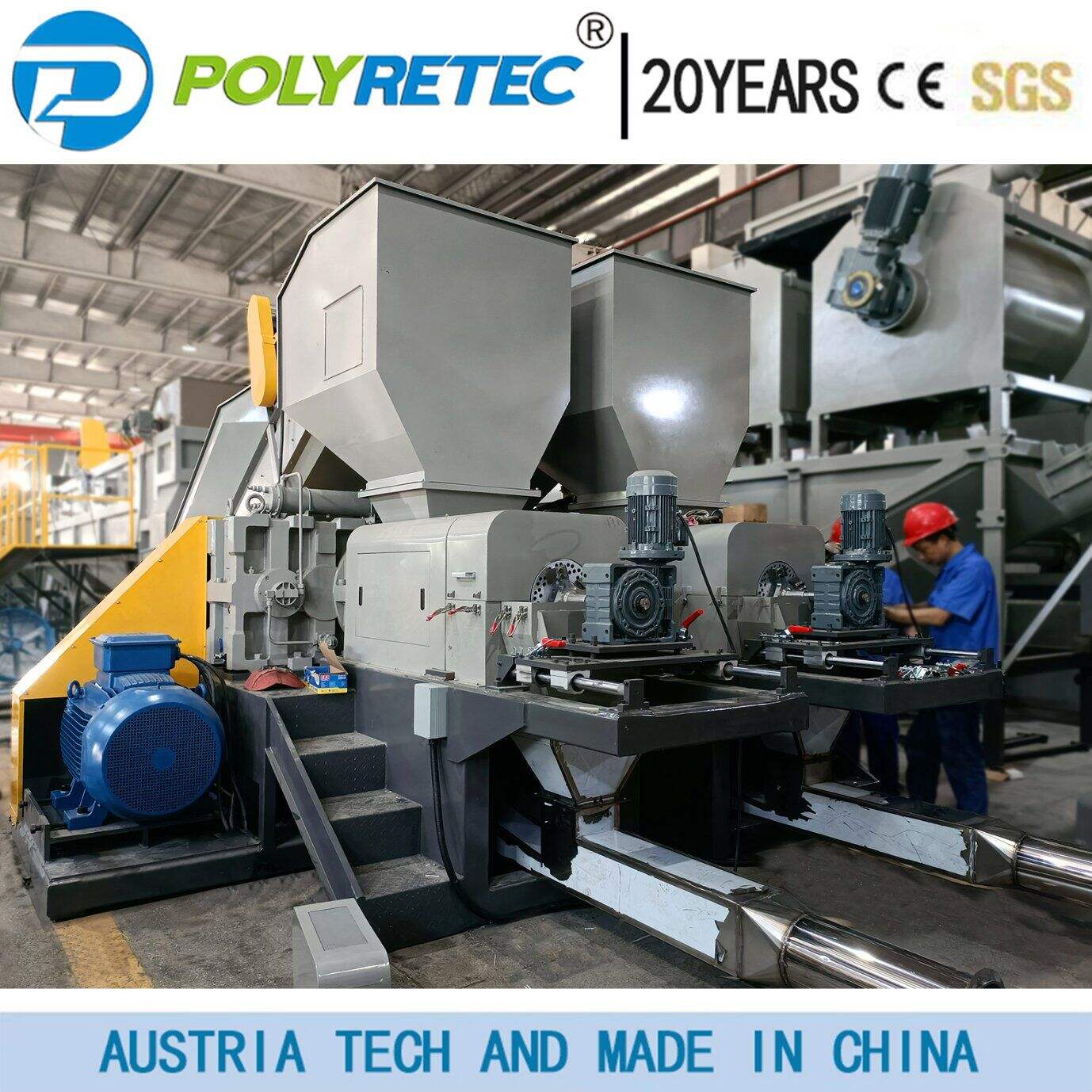

hdpe plastic recycling machine

The HDPE plastic recycling machine is a sophisticated piece of equipment designed to transform high-density polyethylene waste into reusable plastic materials. This advanced system operates through a comprehensive process that includes sorting, crushing, washing, drying, and pelletizing stages. The machine effectively processes various HDPE products, including bottles, containers, and industrial waste materials, converting them into high-quality recycled pellets. Its automated feeding system ensures continuous operation, while precise temperature control mechanisms maintain optimal processing conditions throughout the recycling cycle. The machine's robust construction features wear-resistant components that guarantee long-term durability and consistent performance. Advanced screening technology removes contaminants and ensures the final product meets industry quality standards. The system's modular design allows for easy maintenance and upgrades, while its integrated control panel provides real-time monitoring and adjustment capabilities. With processing capacities ranging from 300 to 1000 kg per hour, the machine caters to both small-scale recycling operations and large industrial facilities. The final output consists of clean, uniform pellets suitable for manufacturing new plastic products, contributing significantly to environmental sustainability and circular economy initiatives.