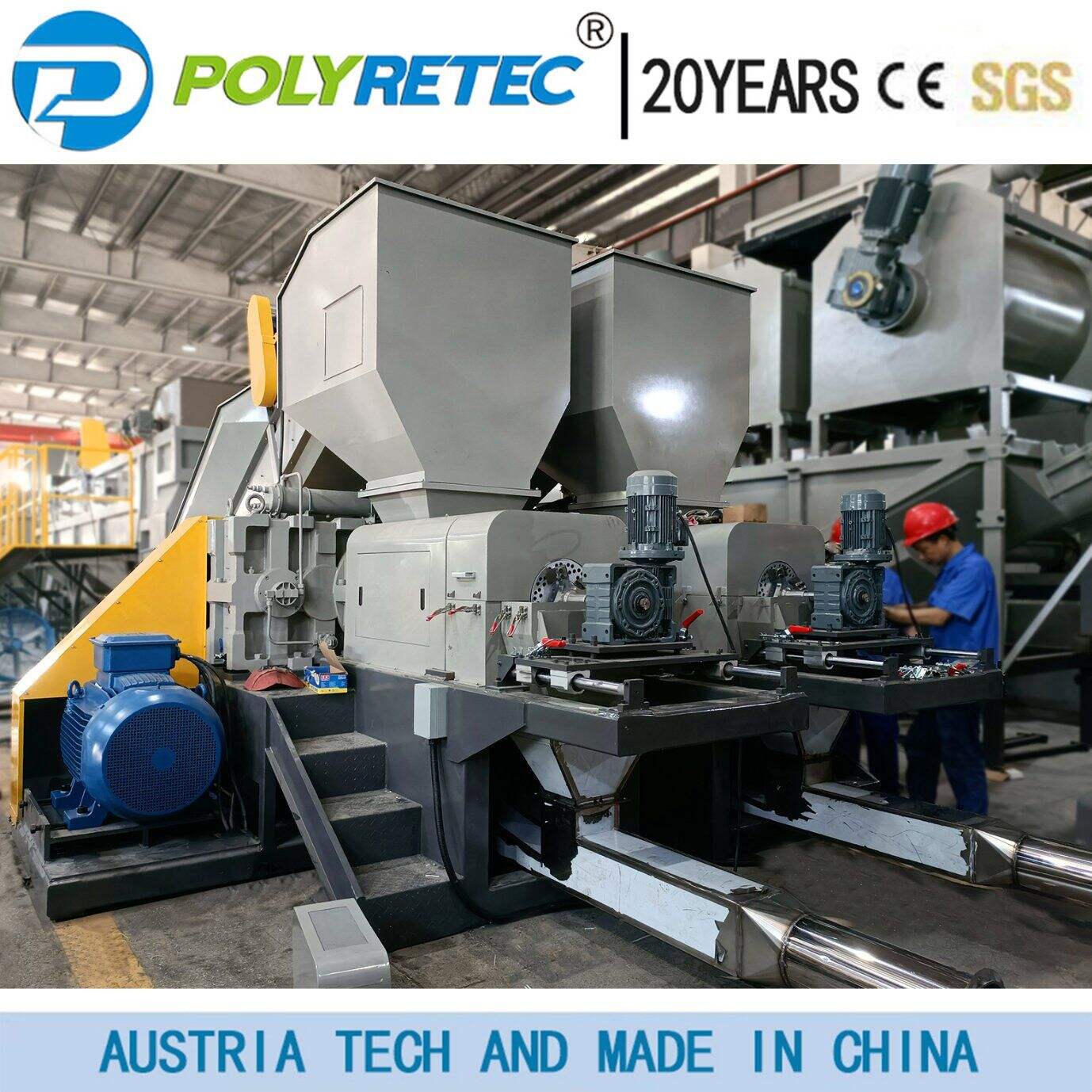

מכונה לאקסטרודר של מחזור פלסטיק

מכונת הפלט התרמית לייצור פלסטיק מוחזר מהווה טכנולוגיה מרכזית בתהליכי 재ycling מודרניים, והיא נועדה להפוך פלסטיק מיותר לمنتجات מוחזרות מועילות. המכונה המתקדמת פועלת בתהליך שיטתי שמתחיל בהאכלה של הפסולת הפלסטית לפה הטעינה, שם היא עוברת מיון וניקוי זהירים. החומר מתקדם דרך תא חימום שבו הוא נמס בטמפרטורות מבוקרות במדויק, בדרך כלל בטווח של 130 עד 350 מעלות צלזיוס, תלוי בסוג הפלסטיק. הפלסטיק המומס נדחף לאחר מכן דרך בורג אקסטרודר, המשווה את החומר ומסיר זיהומים. מערכת הבקרה המתקדמת של המכונה שומרת על טמפרטורה ולחץ קבועים לאורך כל התהליך, ומבטיחה תוצרת באיכות גבוהה. החומר האקסטרודowany יכול לקבל צורות שונות – גרגירים, דפים או פרופילים – בהתאם לצורת היציקה (דיאו) שבה נעשה שימוש. אקסטרודרים מודרניים לייצור פלסטיק מוחזר מצוידים במערכות שימור מתקדמות שמביאות בחשבון מדדי ביצועים ושיטתי זרימה של החומר בזמנ אמת, ומאפשרות התאמות מיידיות לצורך אופטימיזציה של הייצור. המכונות יכולות לעבד מגוון סוגי פלסטיק, בהם PE, PP, PS ו-ABS, מה שהופך אותן לפתרונות גמישים למעבדות 재ycling, מפעלים לייצור ותהליכי ניהול פסולת.