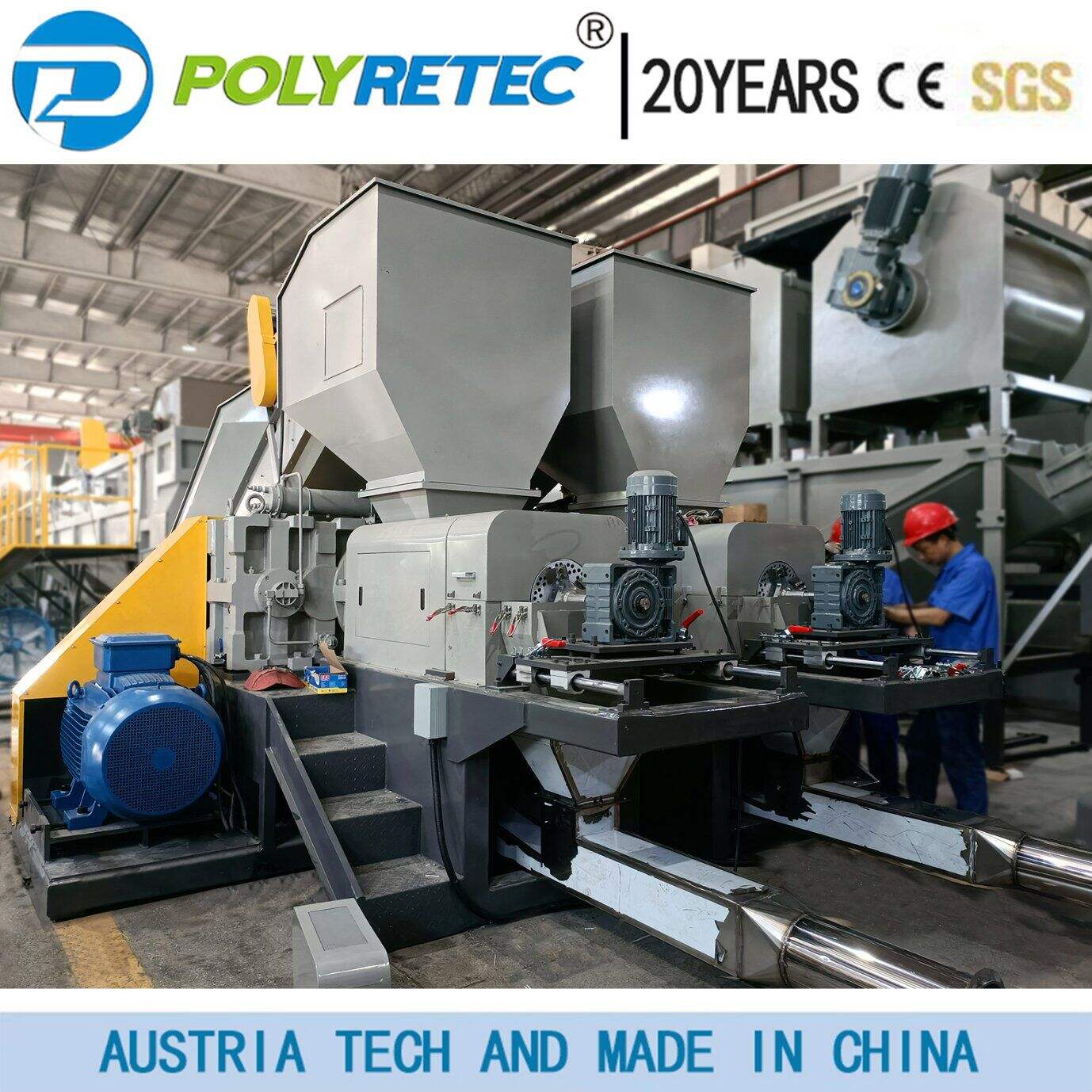

plastic recycling equipment

Plastic recycling equipment represents a comprehensive solution for transforming waste plastic materials into valuable recycled products. These sophisticated machines incorporate multiple processing stages, including sorting, crushing, washing, drying, and pelletizing systems. The equipment utilizes advanced sensor technology and automated sorting mechanisms to efficiently separate different types of plastics, ensuring optimal recycling outcomes. The crushing system features hardened steel blades that reduce plastic waste to uniform sizes, while the washing system removes contaminants and labels using eco-friendly cleaning agents. The drying process employs high-efficiency centrifugal technology and hot air systems to achieve optimal moisture removal. The pelletizing stage transforms the processed plastic into uniform, high-quality pellets ready for reuse in manufacturing. These systems are designed to handle various plastic types, including PET, HDPE, LDPE, and PP, with processing capacities ranging from 500 to 3000 kg per hour. The equipment incorporates smart control systems with touch-screen interfaces, allowing operators to monitor and adjust parameters in real-time, ensuring consistent output quality and operational efficiency.