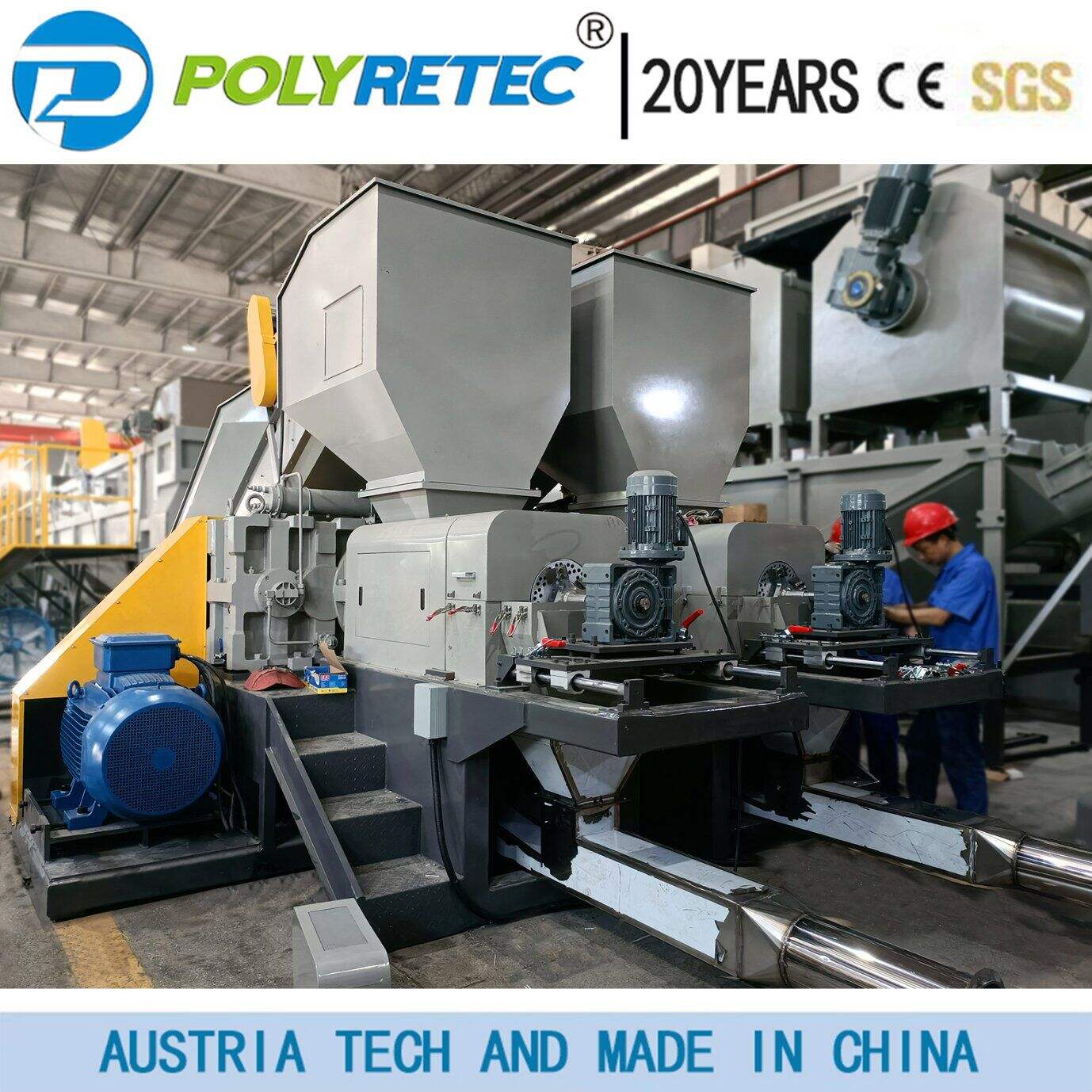

plastic recycling granulator machine

The plastic recycling granulator machine represents a cornerstone in modern recycling technology, designed to efficiently process various plastic materials into uniform granules for reuse. This advanced machinery operates through a sophisticated system of rotating blades and screens, transforming plastic waste into valuable recyclable materials. The machine's core technology centers on its cutting chamber, where high-precision blades rotate at optimized speeds to ensure consistent granule size and quality. With adjustable cutting speeds and customizable screen sizes, it accommodates different types of plastics, from PE and PP to PVC and PET. The granulator features an advanced feeding system that maintains steady material flow while incorporating safety mechanisms to prevent overloading. Its robust construction includes hardened steel blades and wear-resistant components, ensuring longevity and reliable performance. The machine's automatic control system monitors operating parameters, including temperature and motor load, adjusting performance in real-time for optimal results. Applications span various industries, from plastic manufacturing and recycling centers to chemical processing facilities, making it an essential tool in sustainable waste management solutions. The granulator's design prioritizes energy efficiency through optimized motor systems and cutting mechanisms, reducing operational costs while maintaining high throughput rates.