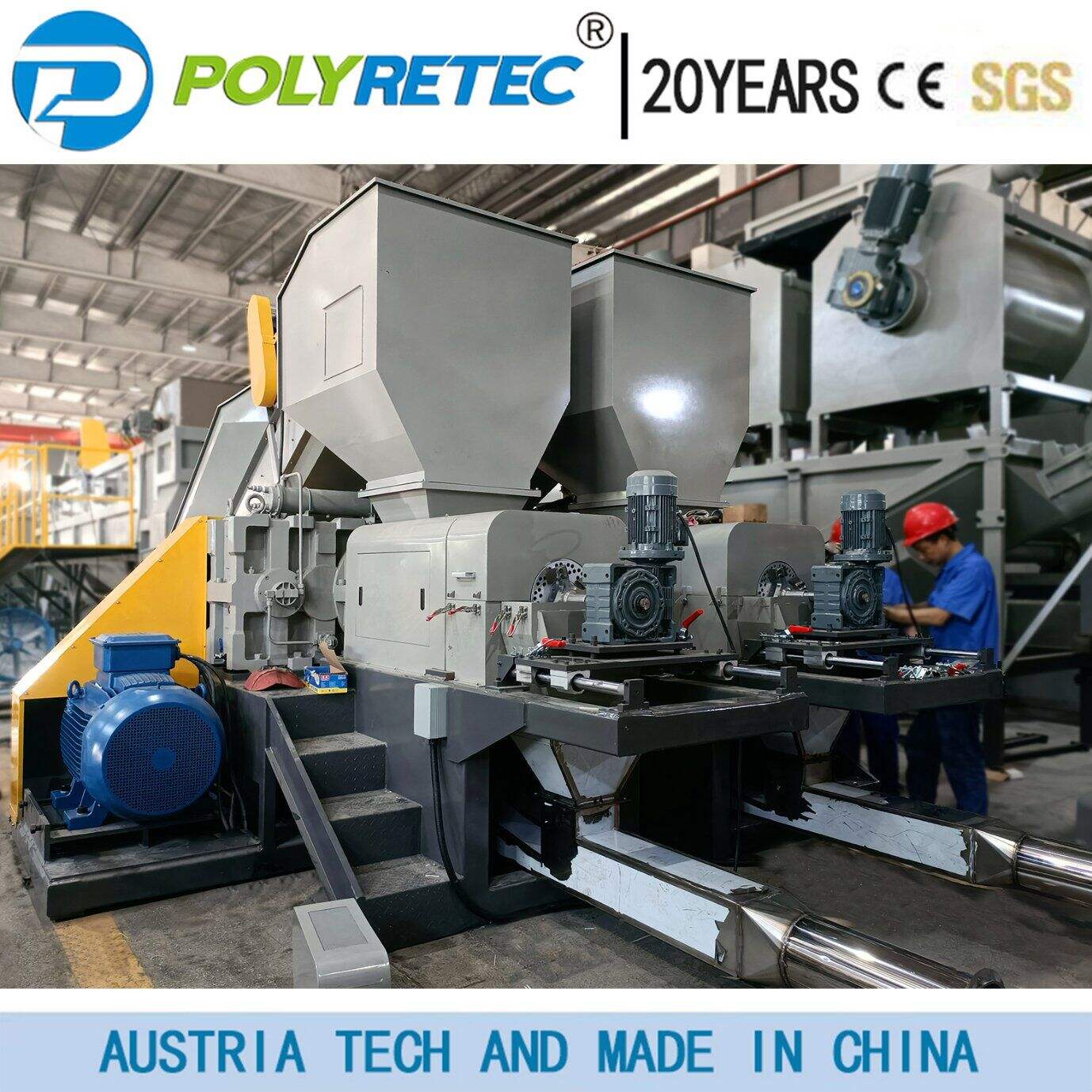

plastic recycling processing plant

A plastic recycling processing plant represents a state-of-the-art facility designed to transform post-consumer and industrial plastic waste into valuable recycled materials. The plant incorporates advanced sorting systems, including optical sensors and artificial intelligence-driven technology, to efficiently separate different types of plastics. The primary processing line features specialized washing units that remove contaminants, labels, and adhesives, ensuring high-quality output. Multiple grinding stations reduce plastic materials to uniform sizes, while advanced extrusion systems melt and reshape the processed plastic into pellets or flakes suitable for manufacturing new products. The facility typically includes quality control stations equipped with spectrometers and density testing equipment to ensure consistent output quality. Environmental control systems manage emissions and water treatment, making the operation environmentally sustainable. The plant can process various plastic types, including PET, HDPE, LDPE, and PP, with throughput capacities ranging from 500 to 5000 kg per hour, depending on the configuration. Modern plants also incorporate automation systems that optimize energy usage and maintain consistent production quality while minimizing human intervention in hazardous processes.