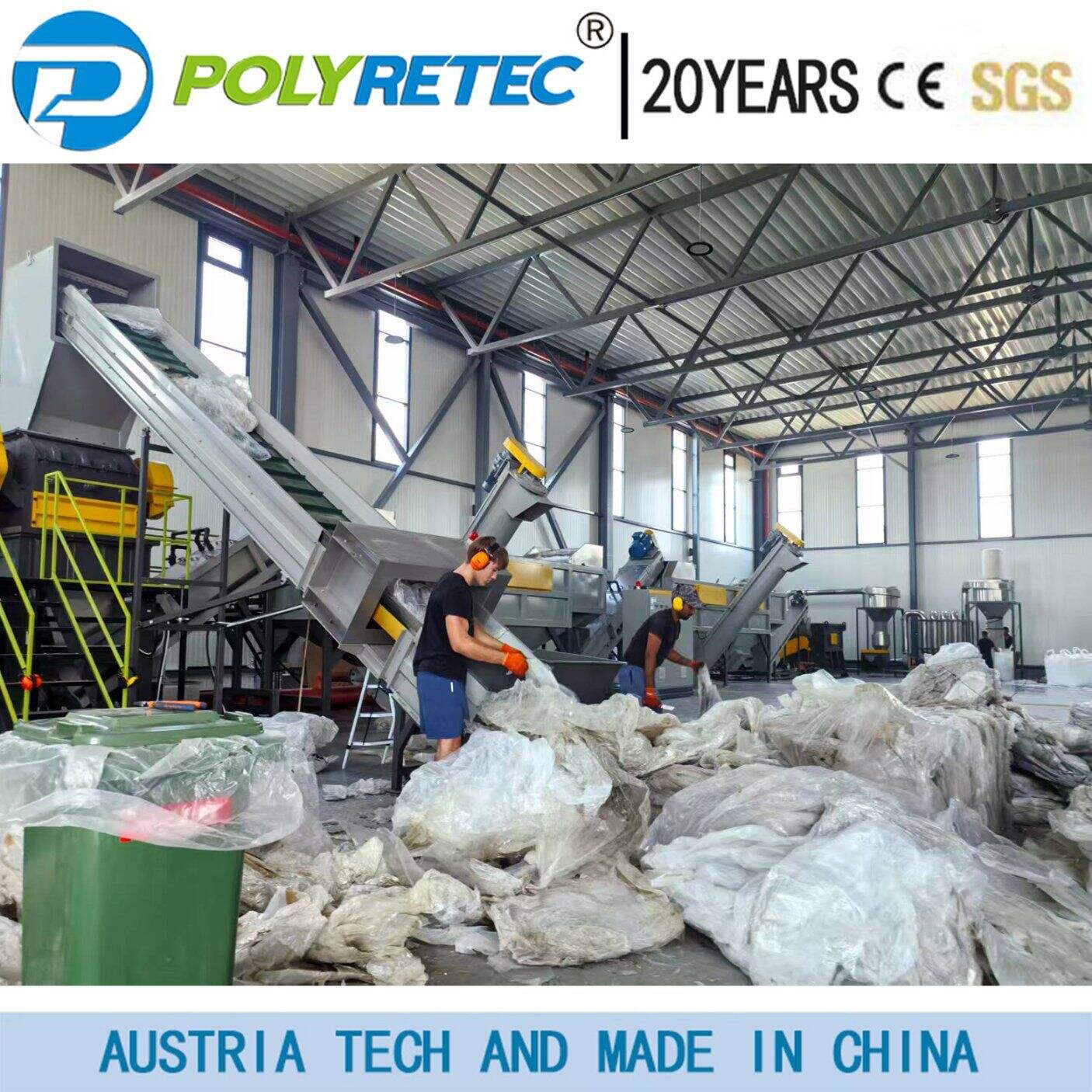

pet bottle crushing plant

A pet bottle crushing plant represents an advanced recycling solution designed to efficiently process and reduce plastic bottle waste. This comprehensive system integrates multiple stages of processing, beginning with automated sorting mechanisms that separate PET bottles from other materials. The plant employs high-precision crushing technology that transforms whole bottles into uniform, clean flakes suitable for recycling. Advanced washing systems remove contaminants, labels, and adhesives, ensuring the output meets industry standards for recycled materials. The plant's sophisticated control system maintains optimal processing parameters, while its modular design allows for scalable operations based on capacity requirements. Key technological features include automatic feeding systems, multiple-stage crushing units, advanced separation technology for removing caps and rings, and integrated drying systems. The plant can process various sizes and types of PET bottles, typically achieving throughput rates of several thousand kilograms per hour. Applications extend beyond basic recycling to support the circular economy, providing high-quality recycled material for manufacturing new products, including textile fibers, packaging materials, and other plastic products. The system's efficiency in reducing waste volume while maintaining material quality makes it an essential component in modern recycling infrastructure.