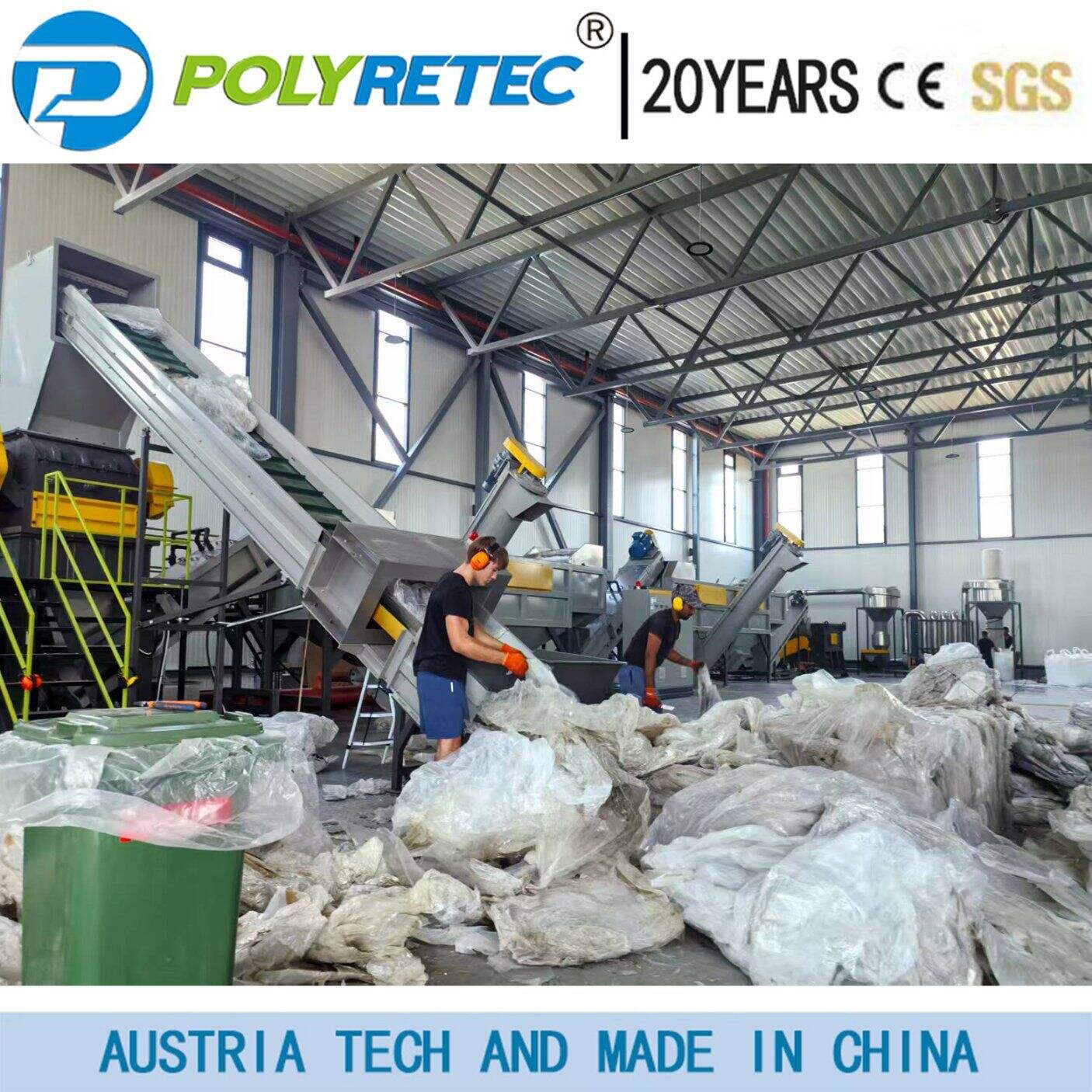

plastic recycling washing plant

A plastic recycling washing plant is an advanced industrial facility designed to transform contaminated plastic waste into clean, reusable plastic materials. The system incorporates multiple stages of processing, beginning with a pre-sorting mechanism that separates different types of plastics. The core washing process utilizes high-efficiency cleaning tanks equipped with friction washers and floating tanks that remove contaminants, labels, and adhesives from plastic materials. Advanced separation technology ensures the removal of non-plastic materials and different density plastics. The plant features automated control systems that monitor water temperature, cleaning agent concentrations, and processing speeds to maintain optimal efficiency. Hot washing sections effectively eliminate stubborn oils and residues, while multiple rinsing stages ensure thorough cleaning. The final drying system, typically utilizing centrifugal or hot air technology, ensures the processed material meets quality standards for recycling. Modern plants are equipped with water treatment and recycling systems, making the process environmentally sustainable. The entire system is designed for continuous operation, processing several tons of plastic waste per hour, making it suitable for both medium and large-scale recycling operations.