plastic recycling plant machine price

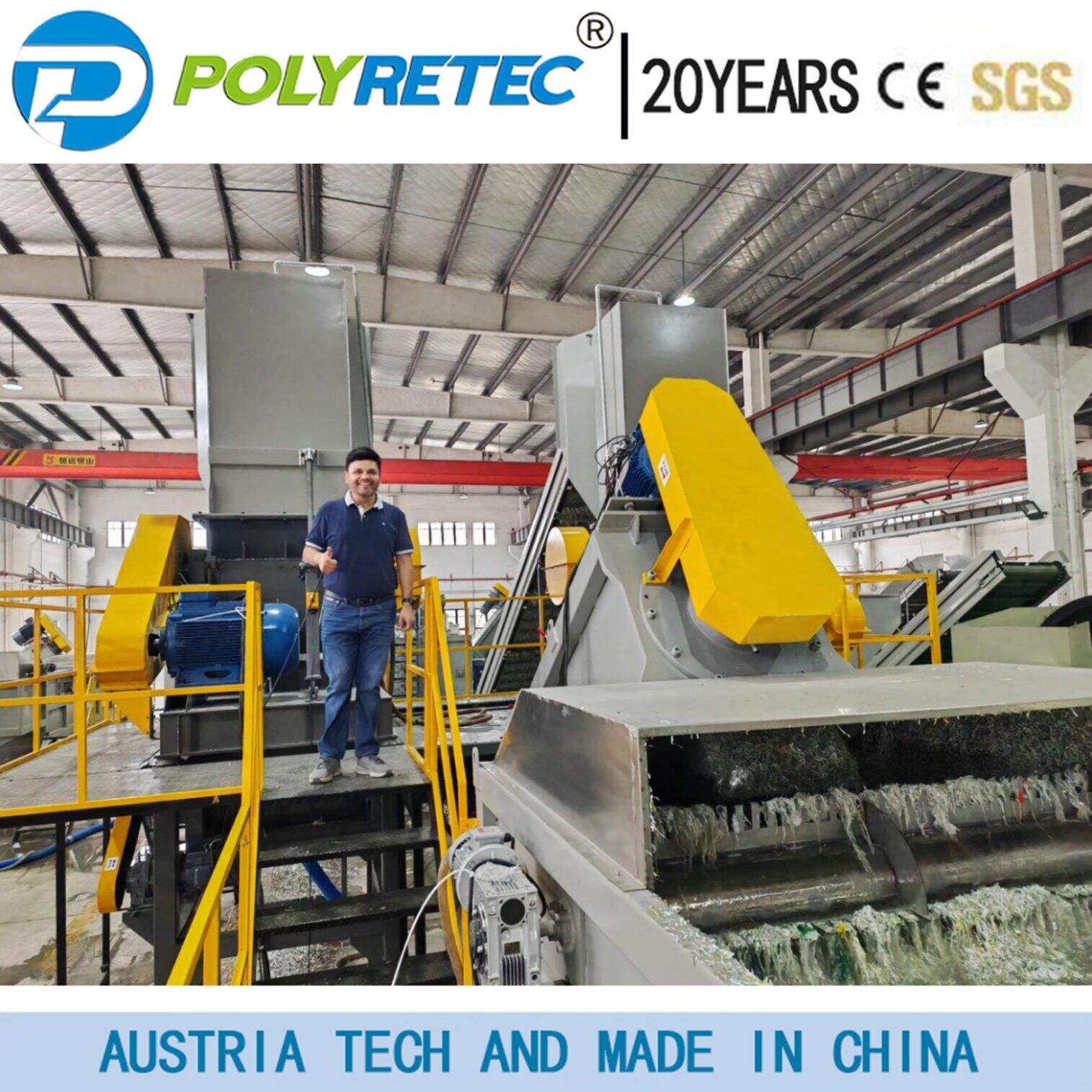

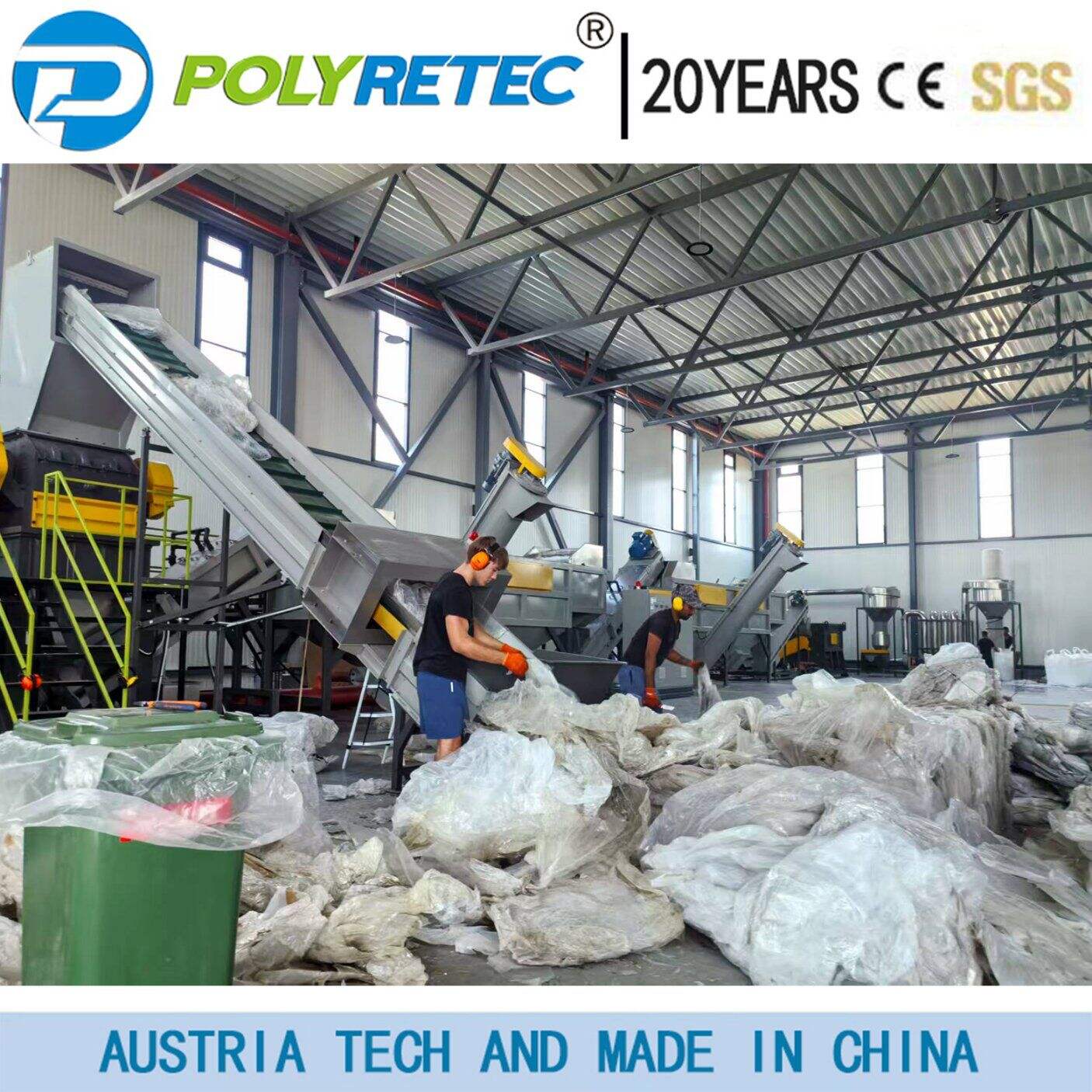

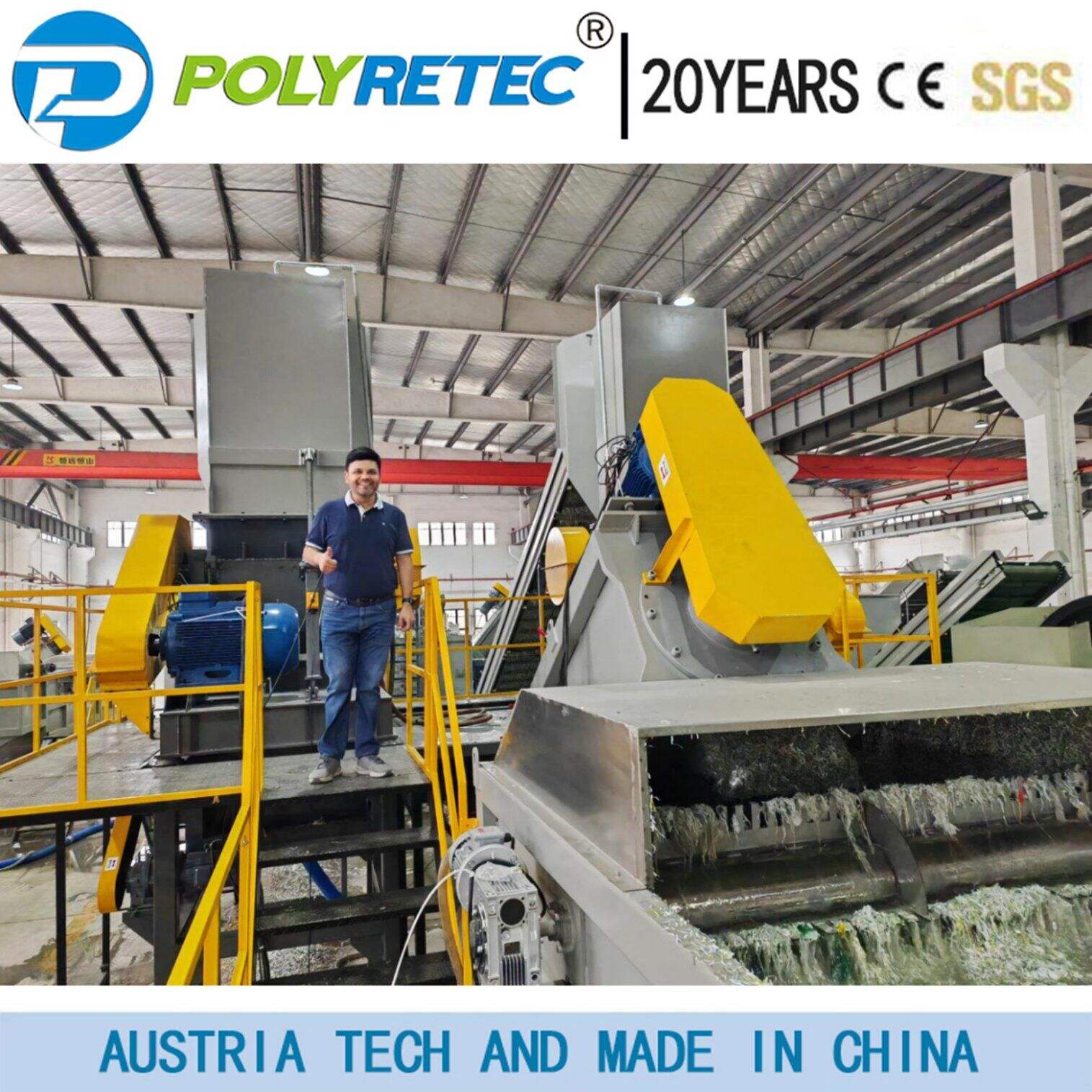

The plastic recycling plant machine price represents a crucial investment consideration in the recycling industry, varying significantly based on capacity, technology, and specifications. These machines typically range from $50,000 to $500,000, offering various processing capabilities from 500kg to 10 tons per day. Modern plastic recycling plants incorporate advanced sorting systems, washing units, crushing mechanisms, and pelletizing equipment, ensuring a comprehensive recycling process. The price structure reflects the sophistication of included technologies, such as automatic sorting systems utilizing NIR sensors, high-efficiency washing systems with hot water capabilities, and precision crushing units that maintain consistent output quality. The machinery's applications span across different plastic types, including PET, HDPE, LDPE, and PP, making it versatile for various recycling operations. Energy efficiency features, automation capabilities, and production capacity significantly influence the final price point. Additional factors affecting the cost include installation requirements, maintenance provisions, and after-sales service packages. These machines are designed to meet international environmental standards while providing optimal operational efficiency and return on investment through reduced labor costs and increased output quality.