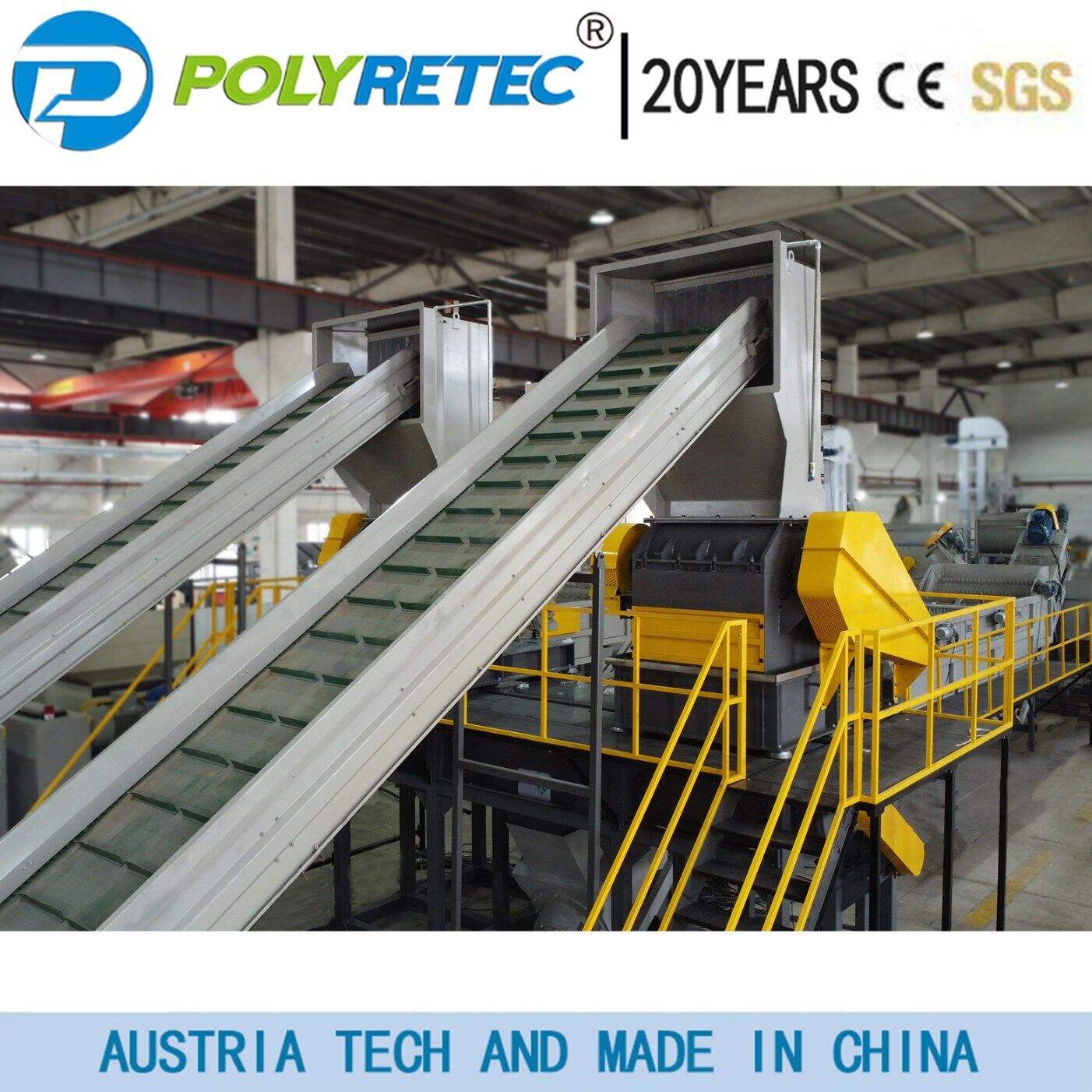

waste plastic recycling equipment

Waste plastic recycling equipment represents a comprehensive solution for transforming plastic waste into valuable recycled materials. This advanced machinery encompasses a complete processing line, including sorting systems, washing units, crushing mechanisms, and pelletizing equipment. The primary function involves breaking down various types of plastic waste into reusable raw materials through mechanical and thermal processes. The equipment utilizes cutting-edge separation technology to sort different plastic types, ensuring optimal recycling efficiency. The washing system removes contaminants and impurities, while the crushing unit reduces plastic waste to uniform sizes. The pelletizing process then converts the processed material into standardized pellets suitable for manufacturing new products. This equipment can handle multiple plastic types, including PET, HDPE, LDPE, and PP, making it versatile for different recycling needs. Advanced control systems monitor and adjust processing parameters in real-time, ensuring consistent output quality. The equipment's modular design allows for customization based on specific capacity requirements and available space, making it suitable for both small recycling operations and large-scale industrial facilities.