plastic recycling small machine

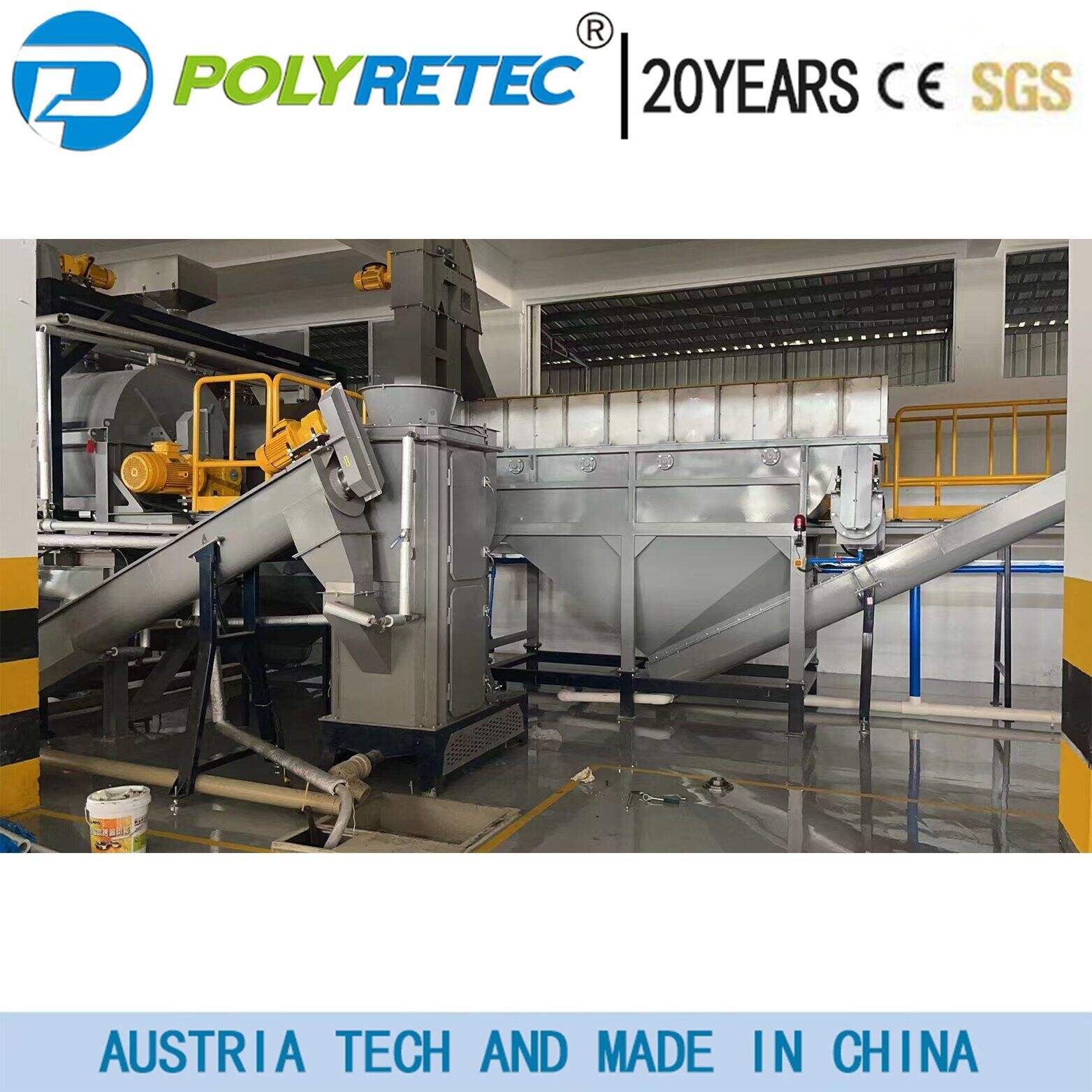

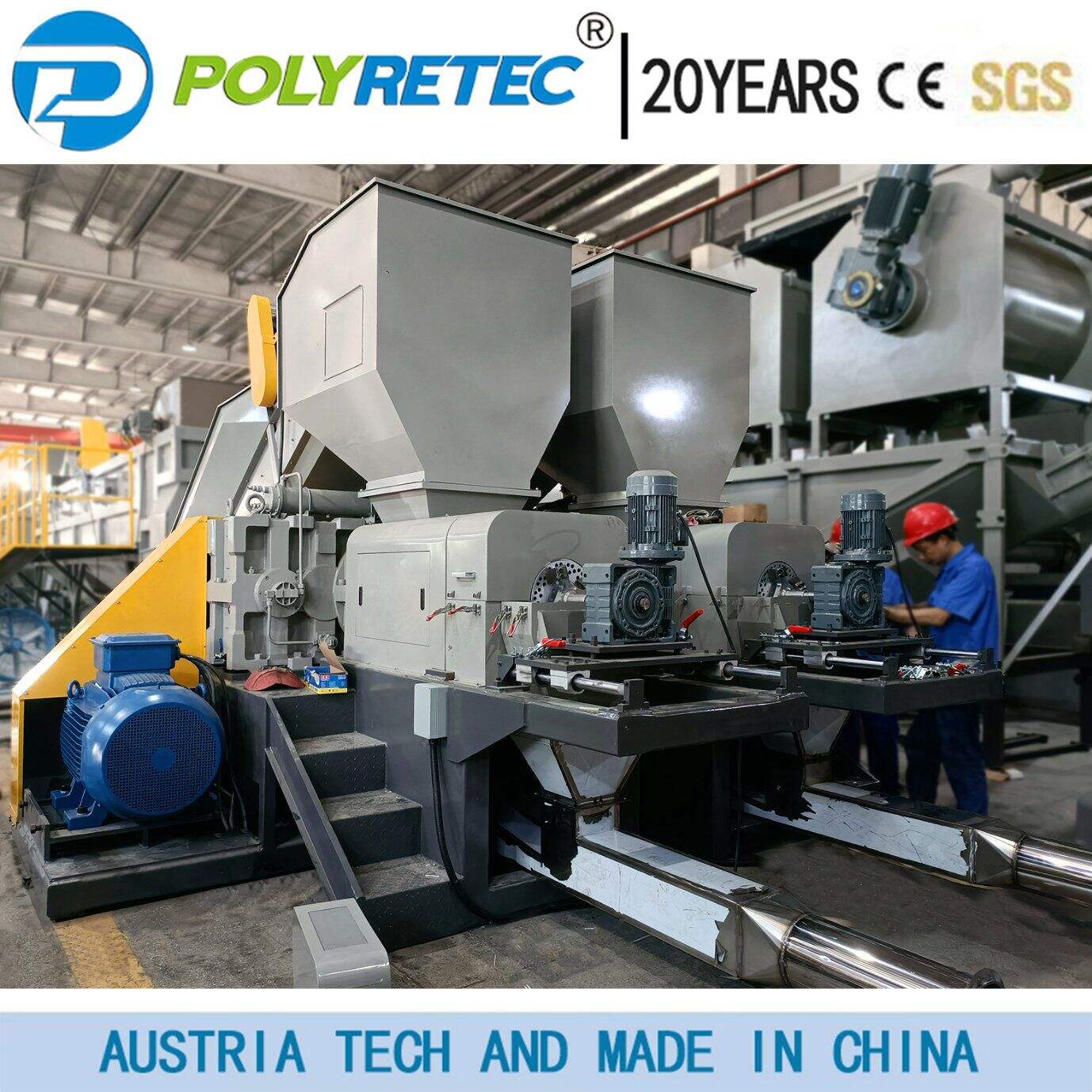

The plastic recycling small machine represents a breakthrough in sustainable waste management technology, designed specifically for small to medium-scale operations. This compact yet powerful unit efficiently processes various types of plastic waste, including PET bottles, HDPE containers, and other common plastic materials. The machine employs a sophisticated multi-stage process, beginning with material sorting and cleaning, followed by size reduction through precision cutting mechanisms. The integrated control system maintains optimal operating parameters, ensuring consistent output quality. With processing capabilities ranging from 50 to 200 kg per hour, depending on the model, these machines are ideal for small businesses, community recycling centers, and manufacturing facilities looking to implement in-house recycling solutions. The machine features advanced safety mechanisms, including emergency shut-off systems and overload protection, while its modular design facilitates easy maintenance and component replacement. The resulting recycled plastic pellets meet industry standards for quality and consistency, making them suitable for various manufacturing applications. Energy-efficient operation and minimal space requirements make this machine an economical choice for organizations looking to contribute to environmental sustainability while maintaining operational efficiency.