ldpe plastic recycling machine

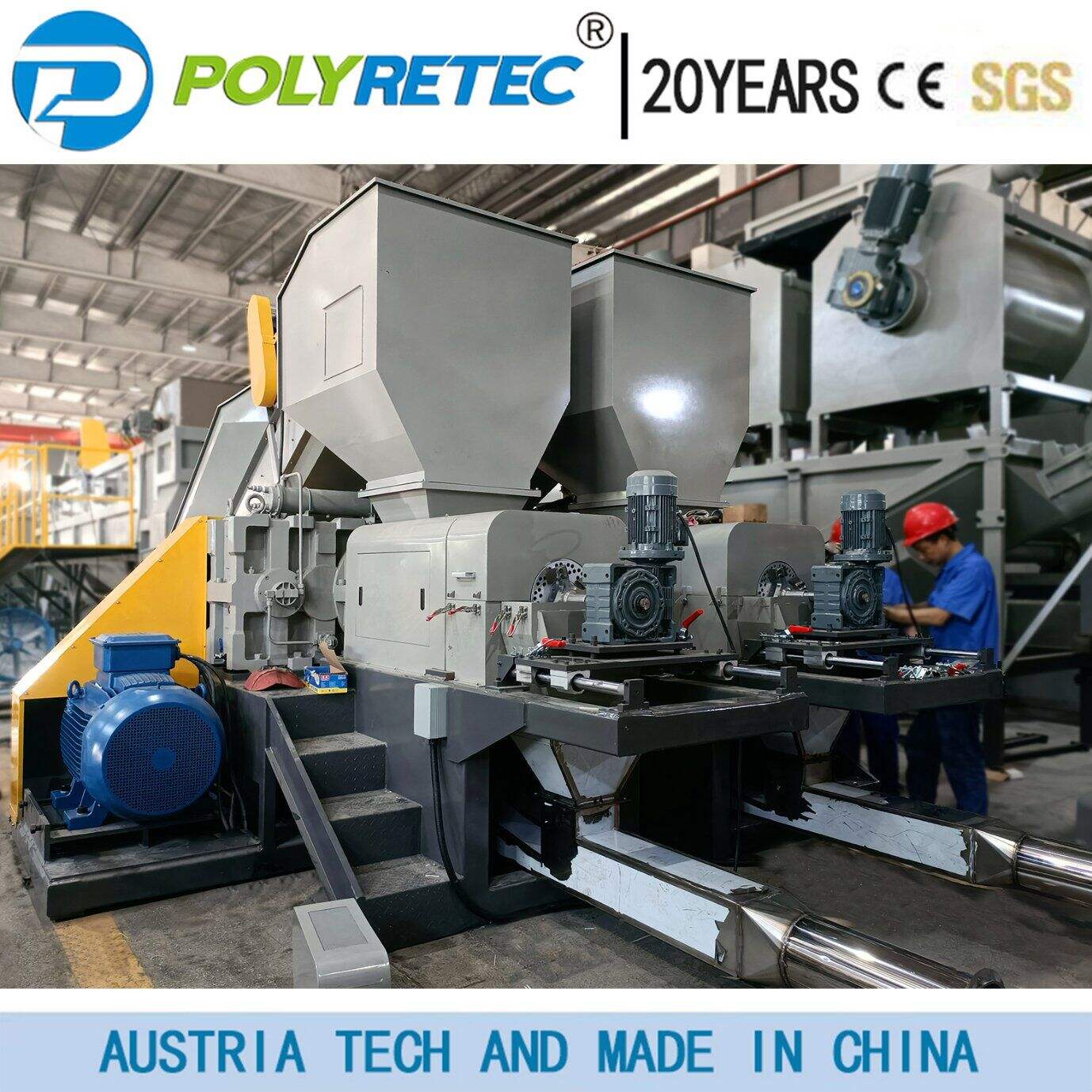

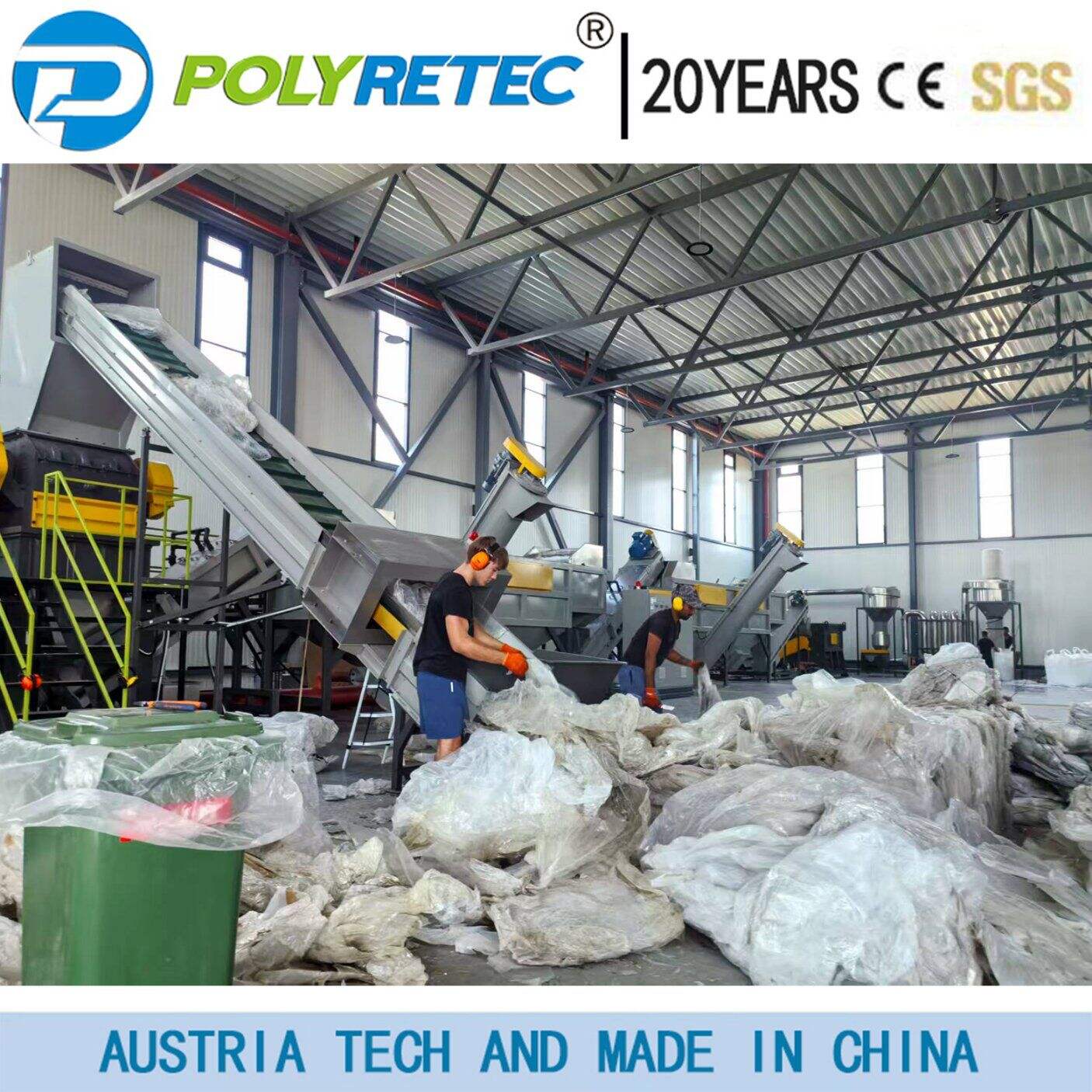

The LDPE plastic recycling machine represents a cutting-edge solution for transforming low-density polyethylene waste into valuable recycled materials. This advanced system incorporates a comprehensive processing line that begins with material sorting and cleaning, followed by efficient size reduction through precision cutting mechanisms. The machine features sophisticated heating and extrusion systems that ensure optimal melting and reformation of LDPE materials, maintaining consistent quality throughout the recycling process. With adjustable temperature controls and variable speed settings, operators can fine-tune the process for different types of LDPE waste materials. The system includes advanced filtration technology that removes contaminants and ensures the final product meets high-quality standards. Modern LDPE recycling machines are equipped with smart control panels that monitor and adjust processing parameters in real-time, maximizing efficiency and reducing waste. These machines can handle various forms of LDPE waste, including films, bags, and packaging materials, processing them into high-quality pellets suitable for manufacturing new products. The system's modular design allows for easy maintenance and upgrades, while its robust construction ensures reliable long-term operation in industrial environments.