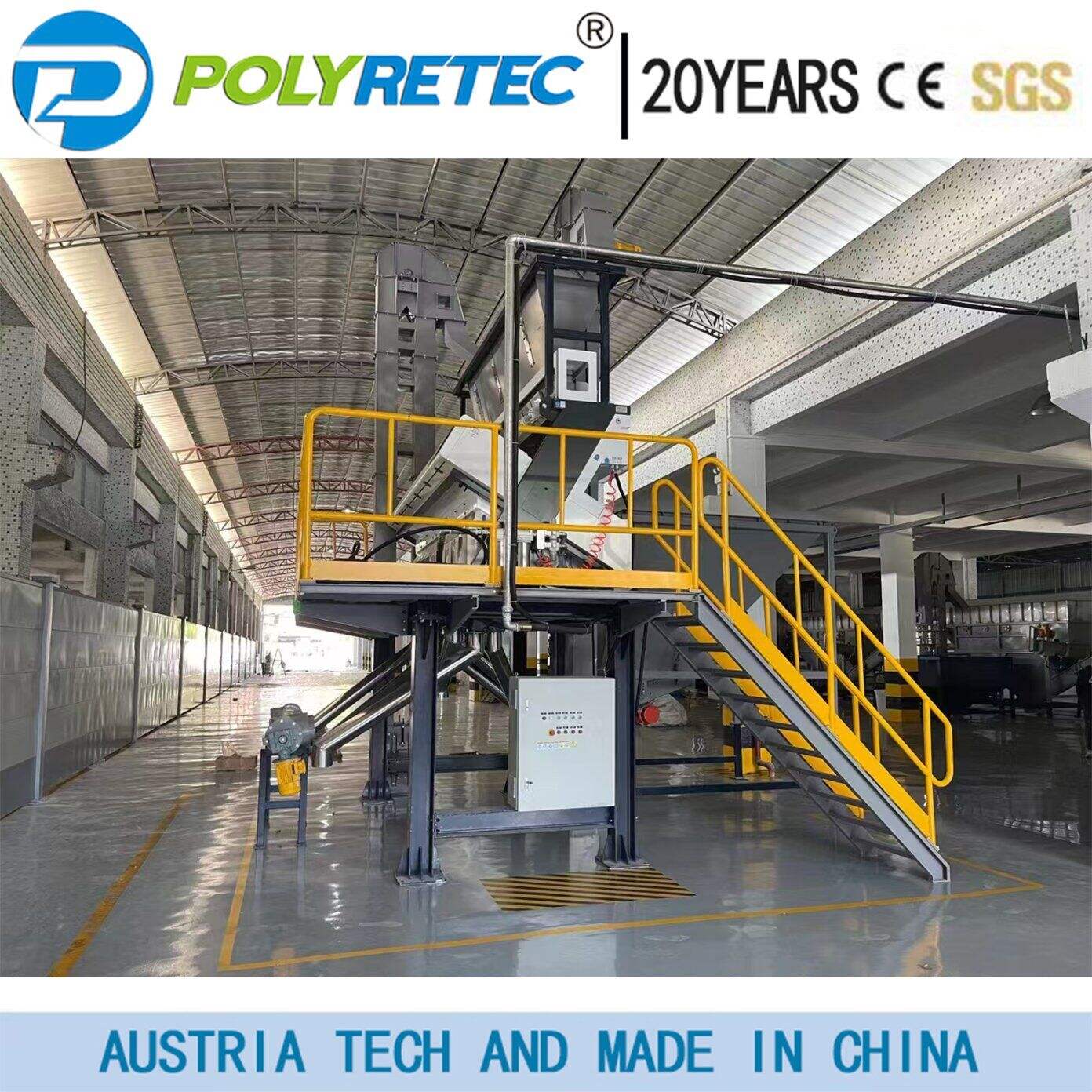

plastic recycling equipment for sale

Plastic recycling equipment for sale represents a comprehensive solution for businesses looking to enter or expand their recycling operations. These state-of-the-art systems incorporate multiple processing stages, including sorting, washing, crushing, and pelletizing capabilities. The equipment features advanced sensor technology for accurate material identification, ensuring optimal sorting efficiency and high-quality output. The washing system employs a multi-stage cleaning process with specialized detergents and hot water treatments to remove contaminants, labels, and adhesives. The crushing mechanism utilizes hardened steel blades and adjustable cutting chambers to process various plastic types, from soft films to rigid containers. The pelletizing system includes precise temperature control and uniform heating zones to produce consistent, high-quality recycled plastic pellets. These machines are designed with automated control systems, featuring touch-screen interfaces and real-time monitoring capabilities. The equipment's modular design allows for easy maintenance and future upgrades, while its energy-efficient motors and optimized processing cycles ensure cost-effective operation. Safety features include emergency stop systems, overload protection, and enclosed processing areas, making it suitable for industrial-scale recycling operations.