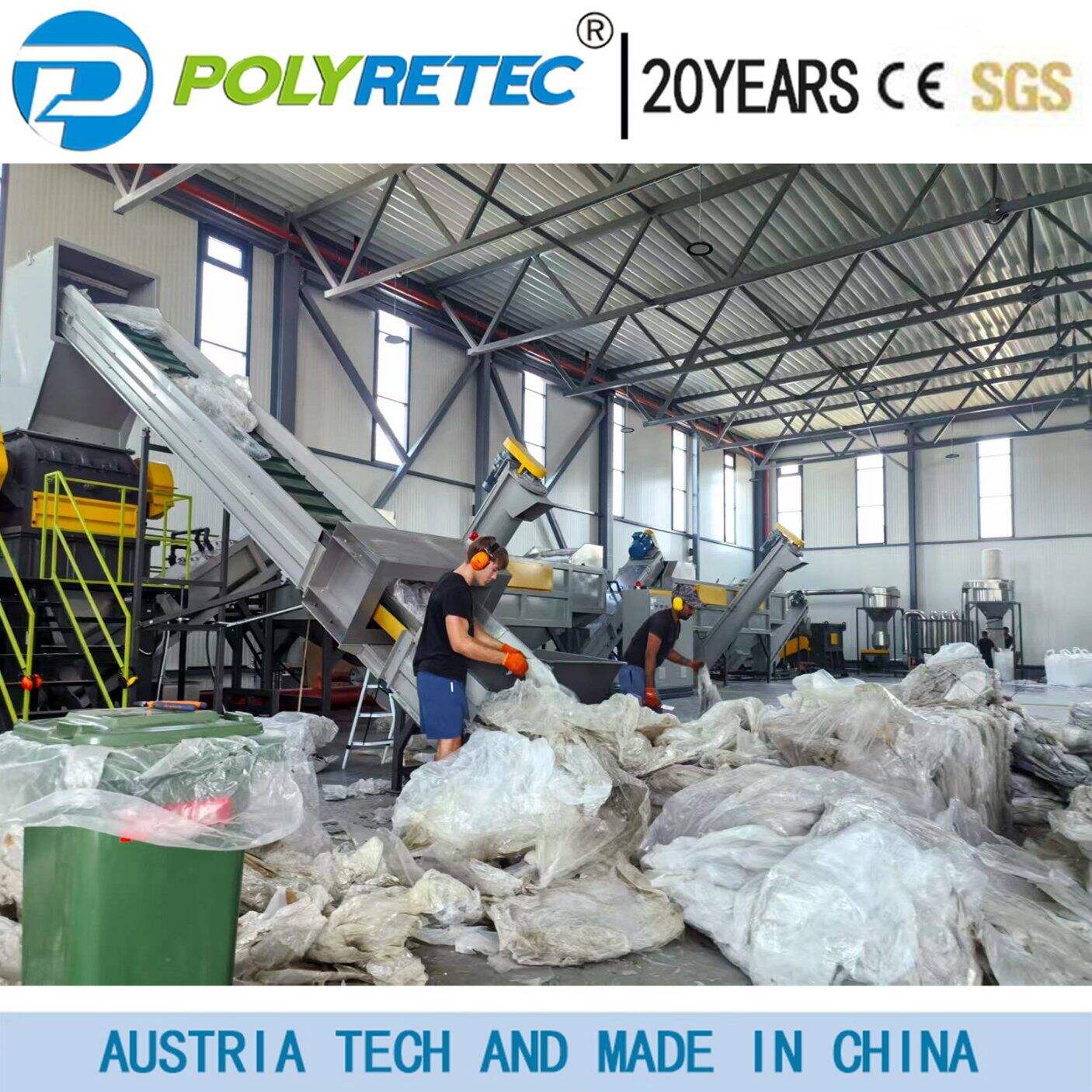

automatic plastic recycling machine

The automatic plastic recycling machine represents a revolutionary solution in waste management technology, combining efficiency with environmental responsibility. This advanced system automates the entire recycling process, from initial sorting to final processing, handling various types of plastic materials including PET, HDPE, and PP. The machine incorporates multiple stages: automatic feeding, sorting, crushing, washing, drying, and pelletizing. Its intelligent sorting system utilizes advanced sensors and AI technology to identify and separate different plastic types with remarkable accuracy, ensuring high-quality output. The crushing mechanism reduces plastic waste to uniform sizes, while the washing system removes contaminants and labels. The drying process employs precision temperature control to prepare materials for pelletizing, where the processed plastic is transformed into high-quality recycled pellets ready for reuse. With processing capacities ranging from 500 to 3000 kg per hour, these machines can be customized to meet various industrial needs. The system's automated control panel provides real-time monitoring and adjustments, ensuring optimal performance while minimizing human intervention. This technology not only supports environmental sustainability but also offers a profitable solution for waste management facilities, manufacturing plants, and recycling centers.