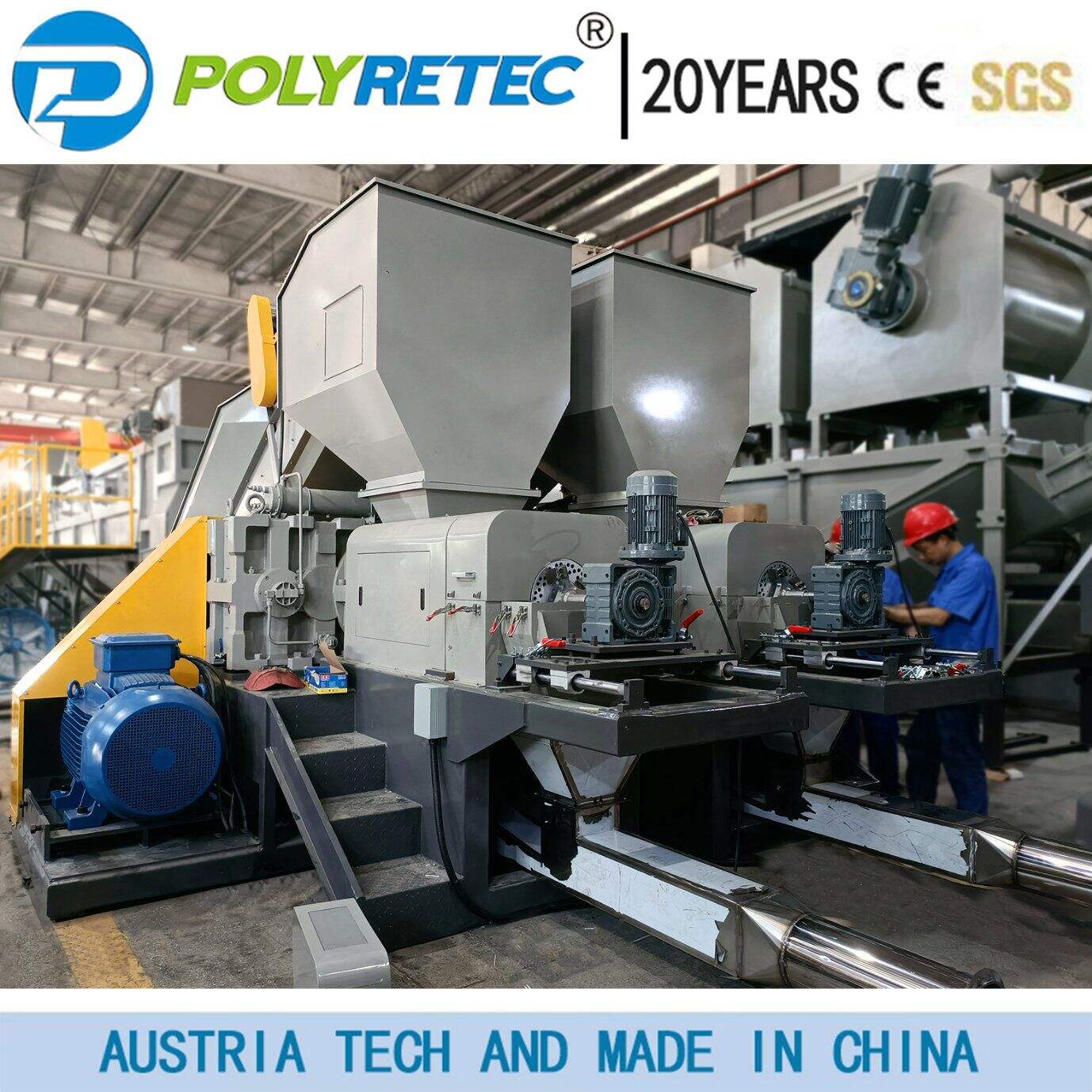

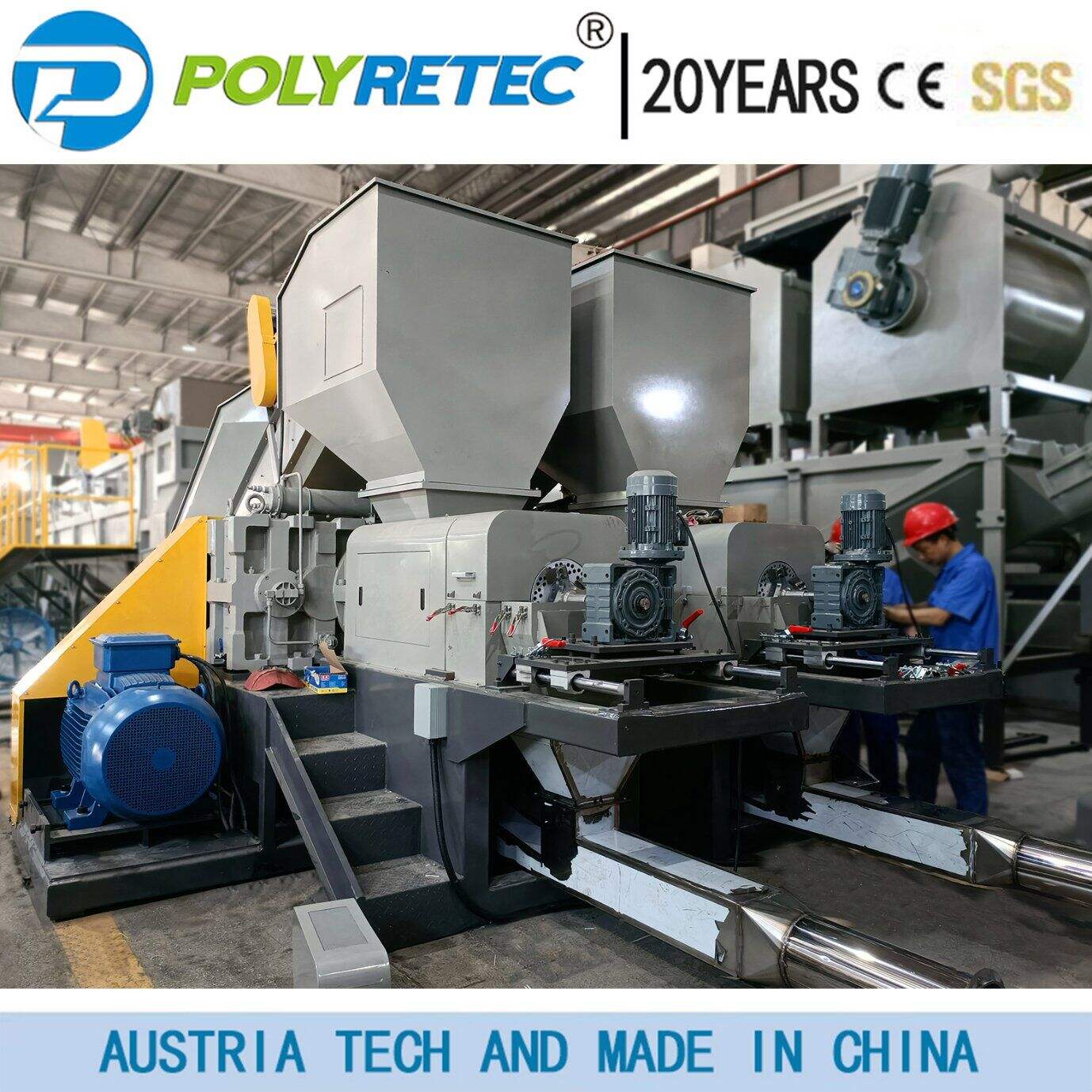

plastic recycling pelletizing machine

The plastic recycling pelletizing machine represents a crucial advancement in sustainable waste management technology, designed to transform plastic waste into valuable recycled pellets. This innovative machine operates through a comprehensive process that begins with the thorough cleaning and sorting of plastic waste materials. The system then proceeds to grind the plastic into smaller pieces before melting them at precisely controlled temperatures. The molten plastic passes through an extruder where it's shaped into uniform strands and subsequently cooled in a water bath. Finally, these strands are cut into consistent-sized pellets ready for reuse in manufacturing. The machine incorporates advanced heating systems and precise temperature controls to ensure optimal processing conditions for different types of plastics. Its robust construction includes wear-resistant components that withstand continuous operation, while the integrated control panel allows operators to monitor and adjust parameters in real-time. The machine's versatility enables it to process various plastic types, including PE, PP, PS, and ABS, making it suitable for diverse recycling applications. This equipment plays a vital role in circular economy initiatives, helping businesses reduce waste while creating valuable raw materials for new plastic products.