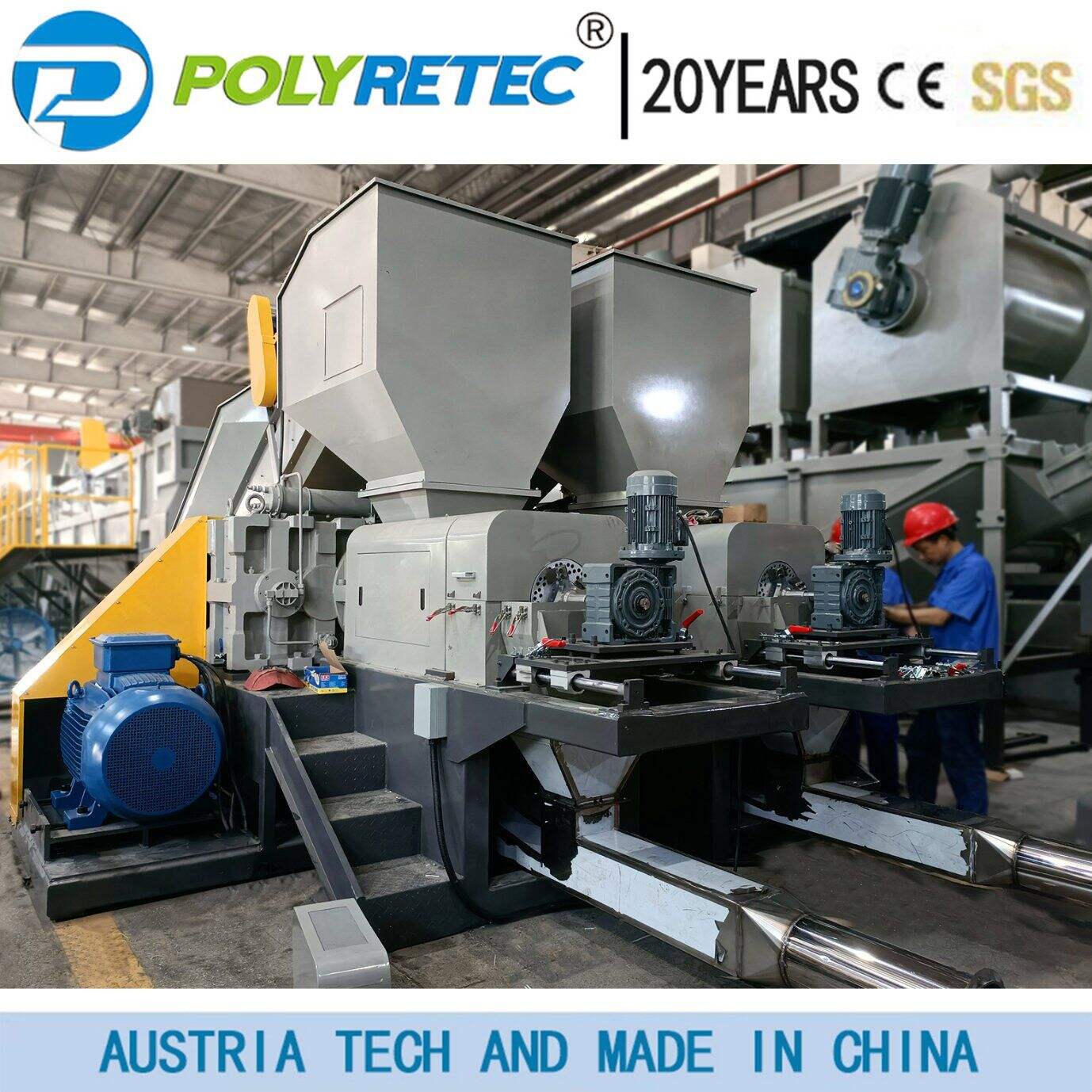

pvc pelletizing machine

A PVC pelletizing machine is a sophisticated piece of equipment designed to transform PVC materials into uniform, high-quality pellets for various industrial applications. This advanced machinery operates through a systematic process that begins with the feeding of raw PVC material into a heated extruder barrel. The material undergoes precise temperature control and mechanical shearing, where it's melted and homogenized to achieve consistent quality. The molten PVC is then forced through specially designed die plates, creating strands that are immediately cooled in a water bath. The cooling process ensures optimal crystallization and pellet formation. Following this, a rotary blade system cuts the strands into uniform pellets of specified sizes, typically ranging from 2mm to 5mm. The machine incorporates advanced control systems that monitor and adjust parameters such as temperature, pressure, and cutting speed in real-time, ensuring consistent pellet quality. Modern PVC pelletizing machines are equipped with automation features that streamline the entire process, from material feeding to final pellet collection, significantly reducing manual intervention and improving operational efficiency. These machines can process various types of PVC compounds, including rigid and flexible PVC, and can achieve production rates of several hundred kilograms per hour, making them essential for plastic processing industries.