plastic pelletizer machine factory

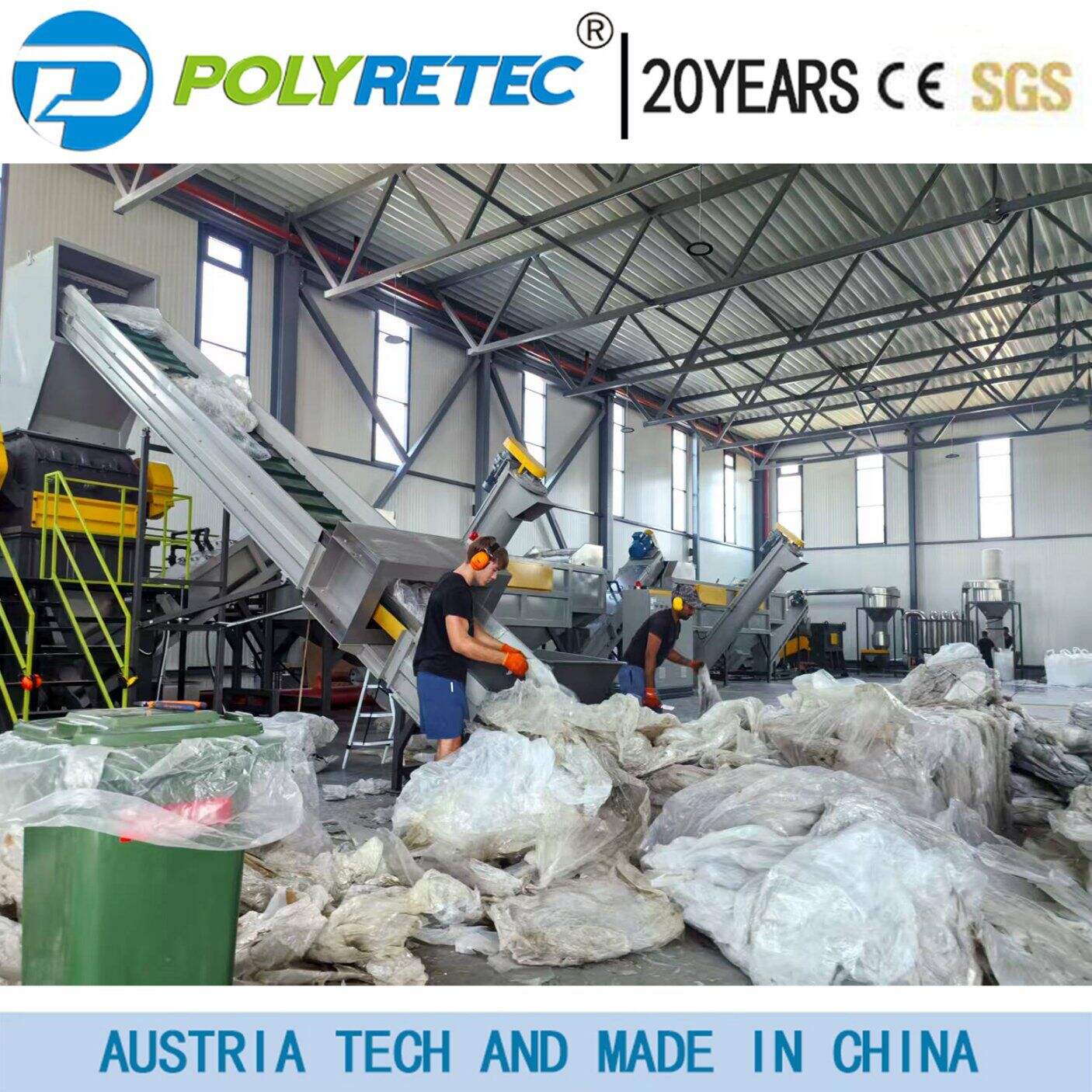

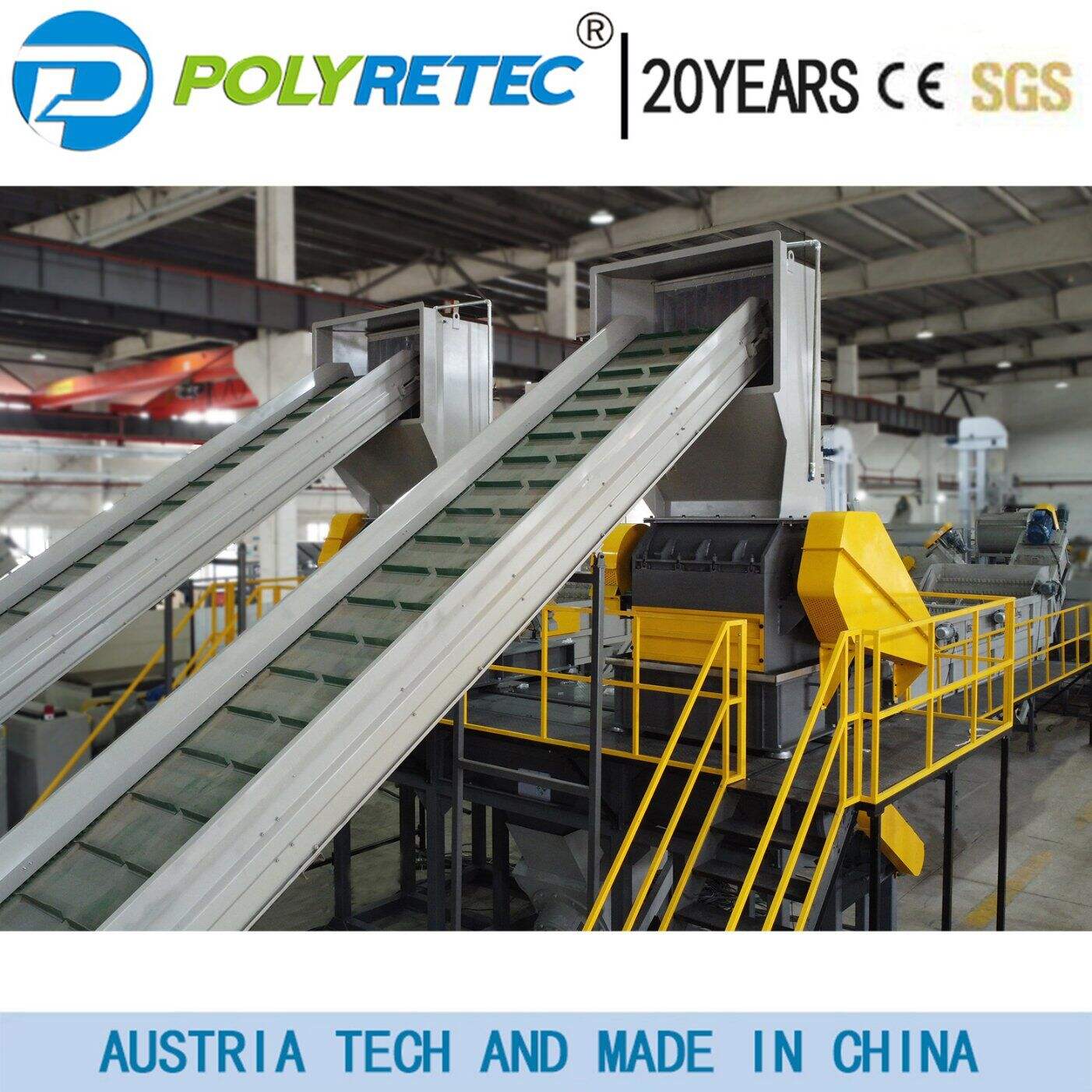

A plastic pelletizer machine factory represents a cornerstone in modern plastic recycling and manufacturing industries. These specialized facilities produce advanced equipment designed to transform plastic materials into uniform, high-quality pellets for various applications. The factory's production line incorporates state-of-the-art technology and precision engineering to ensure consistent output quality. The manufacturing process includes comprehensive quality control systems, automated assembly lines, and rigorous testing protocols. These factories typically produce machines capable of processing different types of plastics, from PET to HDPE, with throughput capacities ranging from 50 to 1000 kg per hour. The facility's expertise extends to customizing pelletizer machines according to specific client requirements, offering various cutting mechanisms, cooling systems, and control interfaces. The production environment maintains strict quality standards, employing skilled technicians and engineers who oversee every aspect of machine assembly. Advanced diagnostic systems are integrated into the manufacturing process to ensure each component meets precise specifications. The factory also maintains research and development facilities to continuously improve machine design and efficiency, incorporating feedback from clients and market demands.