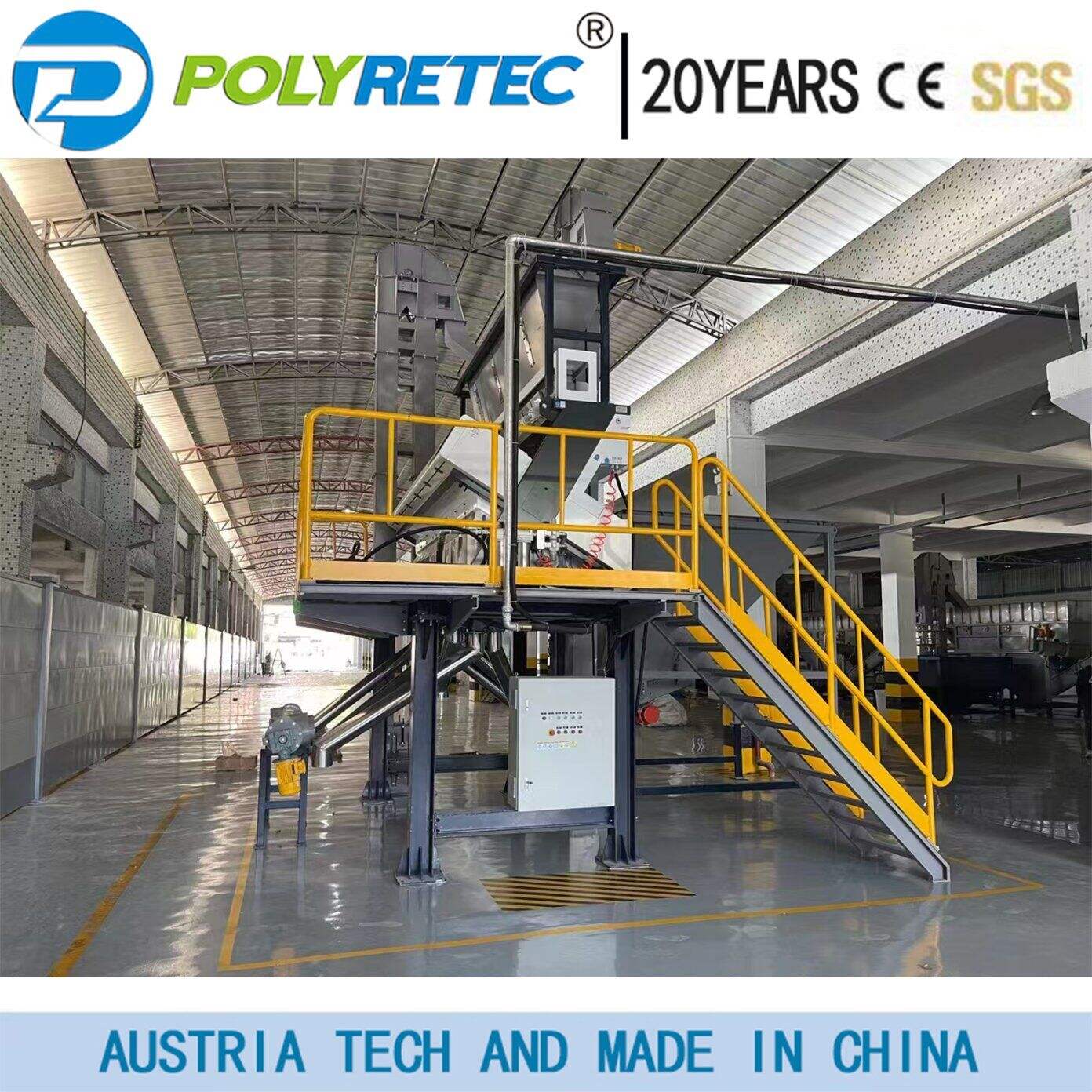

pet bottle washing plant

A pet bottle washing plant represents a cutting-edge solution for recycling and processing used PET bottles into clean, reusable materials. This sophisticated system encompasses multiple stages of washing, sorting, and processing to transform contaminated PET bottles into high-quality recycled material. The plant typically begins with a sorting mechanism that removes non-PET materials and separates bottles by color and quality. Following this, bottles undergo a pre-washing phase where labels, caps, and major contaminants are removed. The core washing process utilizes advanced cleaning agents and hot water treatment to eliminate stubborn dirt, adhesives, and organic residues. High-speed friction washers and multiple rinsing stages ensure thorough cleanliness. The plant incorporates automated quality control systems that monitor cleanliness levels and material integrity throughout the process. Modern plants feature energy-efficient designs with water recycling capabilities, reducing operational costs while maintaining environmental responsibility. The final output consists of clean PET flakes or pellets ready for reuse in various applications, from new bottles to textile fibers. These plants can process several tons of PET bottles per hour, making them ideal for large-scale recycling operations.