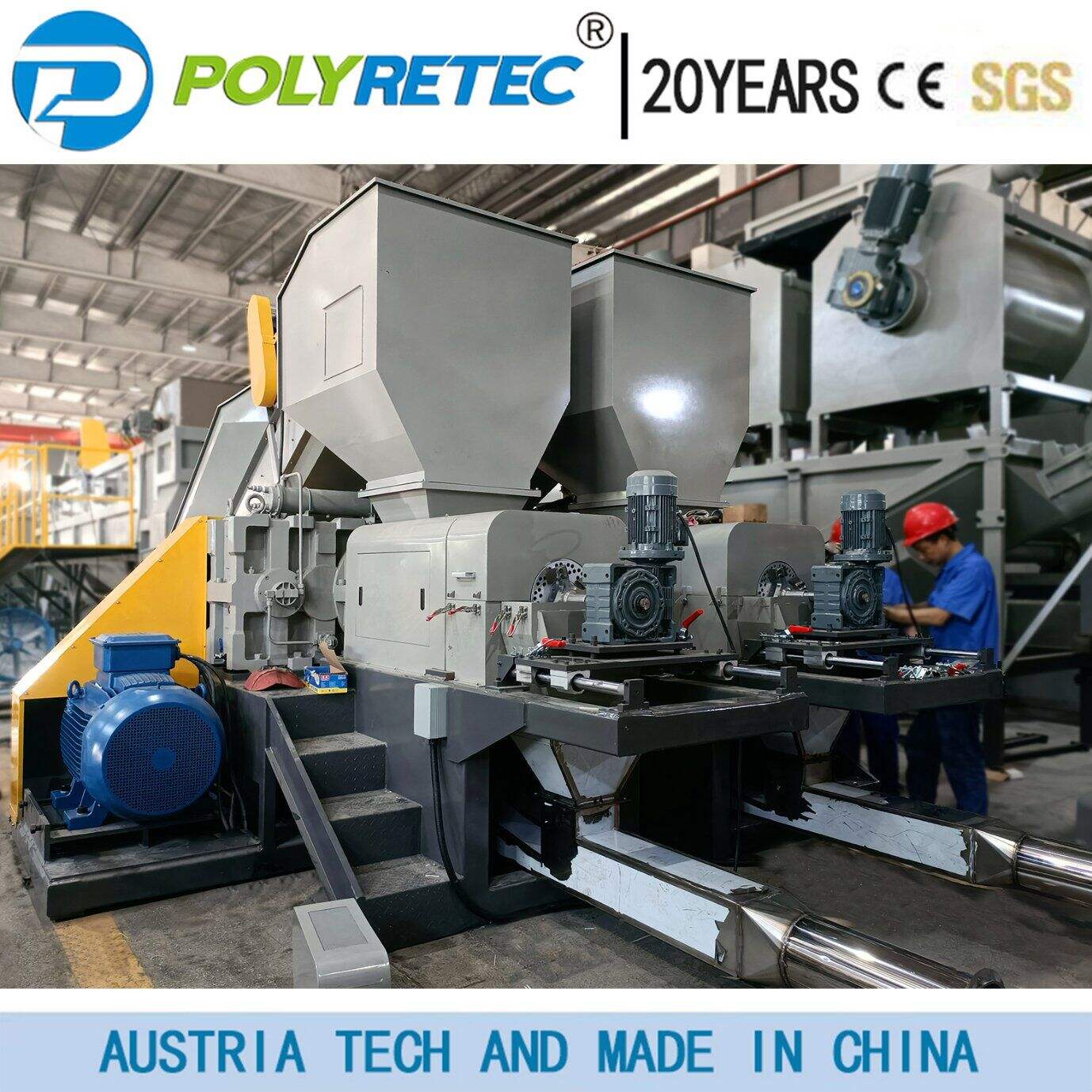

plastic recycling plant equipment

Plastic recycling plant equipment represents a comprehensive solution for transforming waste plastic materials into valuable recycled products. This sophisticated system comprises multiple integrated components, including sorting systems, washing units, crushing machinery, and extrusion equipment. The primary function involves processing various types of plastic waste through a systematic approach, beginning with automated sorting mechanisms that utilize advanced sensors and AI technology to separate different plastic types. The washing phase employs high-pressure cleaning systems and specialized detergents to remove contaminants, while the crushing units reduce plastic materials to uniform sizes for optimal processing. The equipment's technological features include precision control systems, energy-efficient motors, and automated material handling systems that ensure consistent output quality. The plant's application extends across various industries, from post-consumer plastic waste processing to industrial scrap recycling, capable of handling multiple plastic types including PET, HDPE, LDPE, and PP. Modern plants incorporate real-time monitoring systems and adjustable processing parameters to maintain optimal performance and product quality throughout the operation cycle.