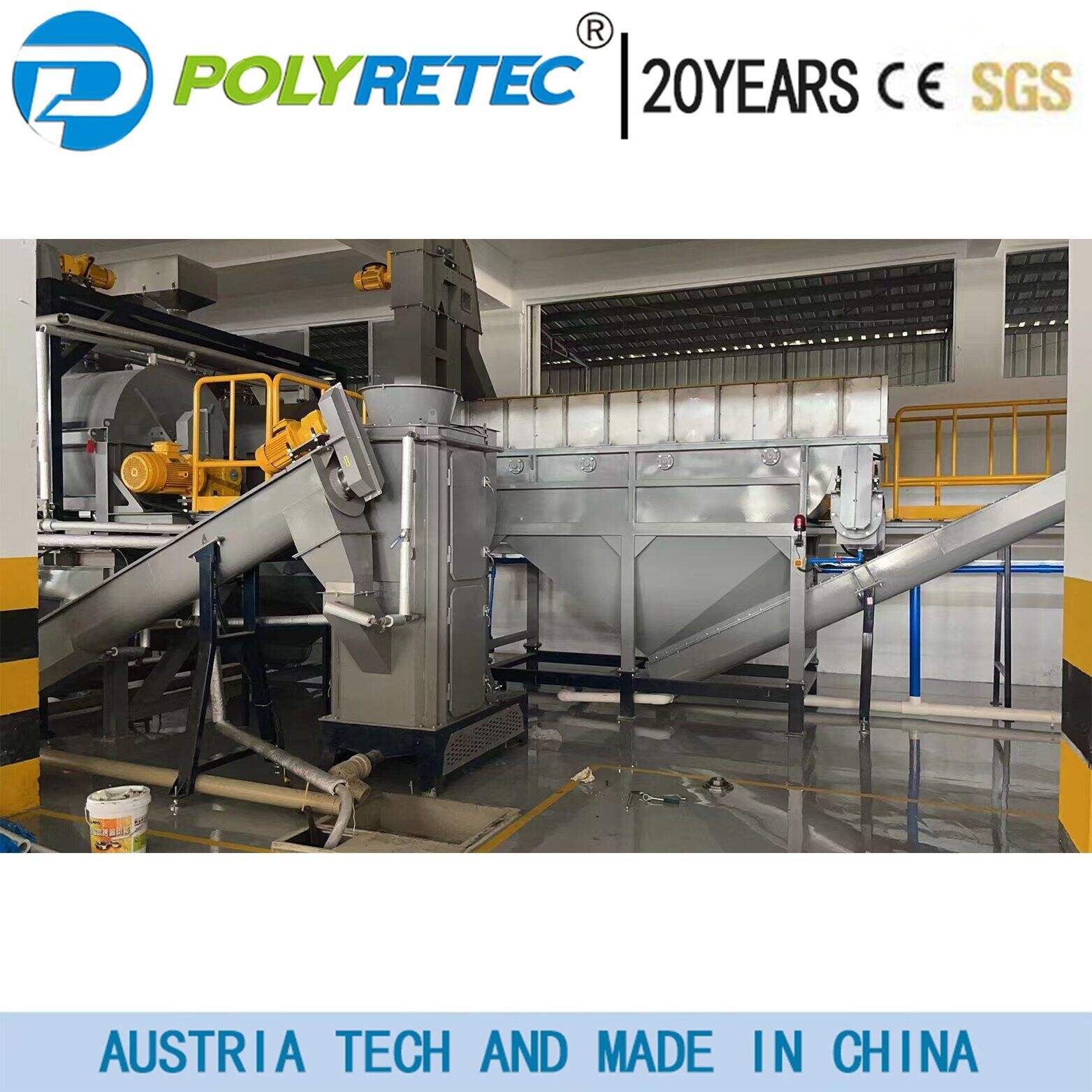

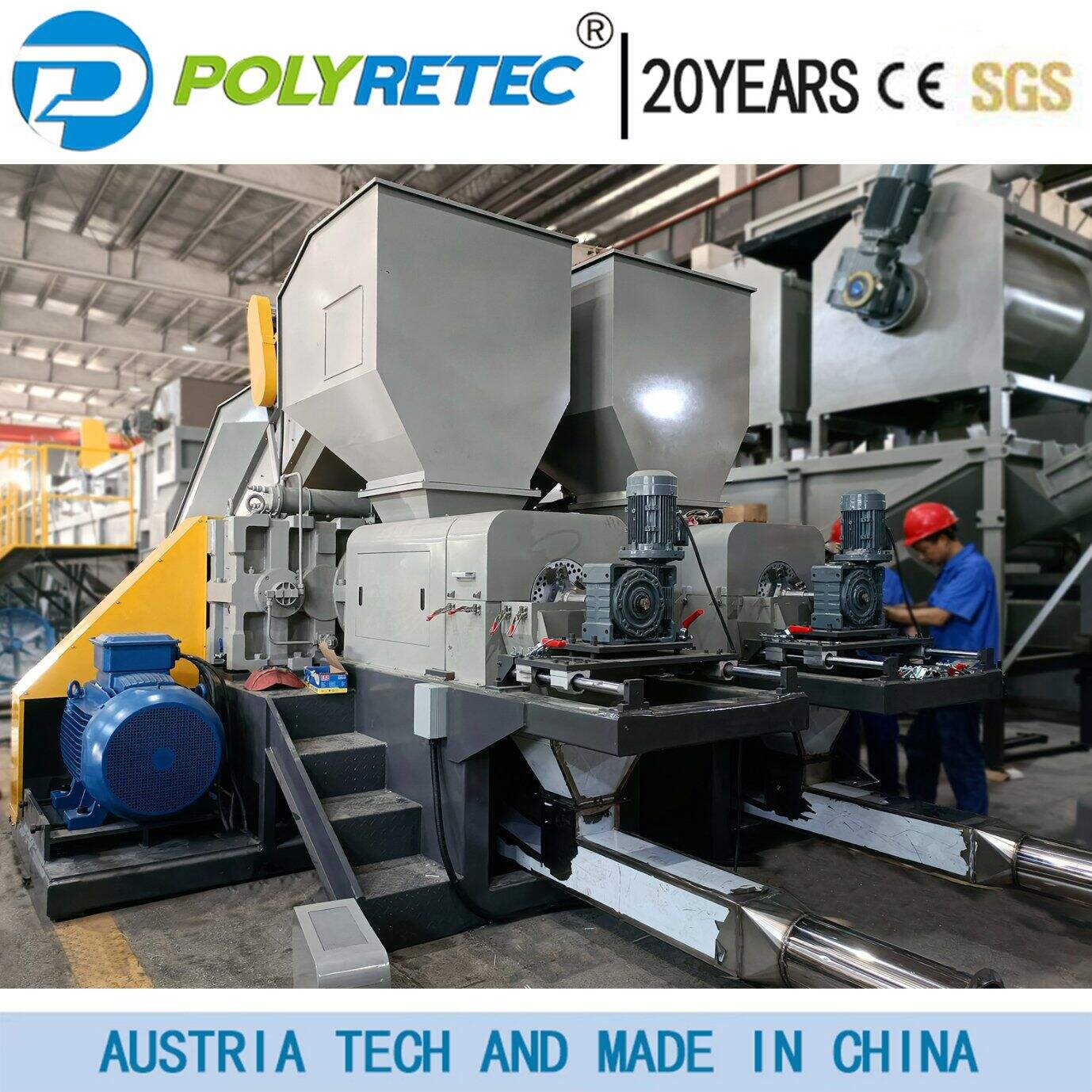

pet recycling plant

A PET recycling plant represents a state-of-the-art facility designed to transform post-consumer PET bottles and containers into valuable recycled materials. The plant employs advanced sorting systems, washing technologies, and extrusion processes to convert waste PET into high-quality recycled products. At its core, the facility features automated sorting mechanisms that efficiently separate PET from other materials using optical sensors and air classification systems. The washing process incorporates hot caustic washing solutions and friction washers to remove contaminants, labels, and adhesives. Following washing, the material undergoes a grinding process, producing clean PET flakes. These flakes then pass through a sophisticated extrusion system, where they are melted, filtered, and transformed into recycled PET pellets suitable for various applications. The plant's advanced control systems monitor quality parameters throughout the process, ensuring consistent output quality. Modern PET recycling plants can process several tons of material per hour, contributing significantly to environmental sustainability while creating valuable raw materials for manufacturing.