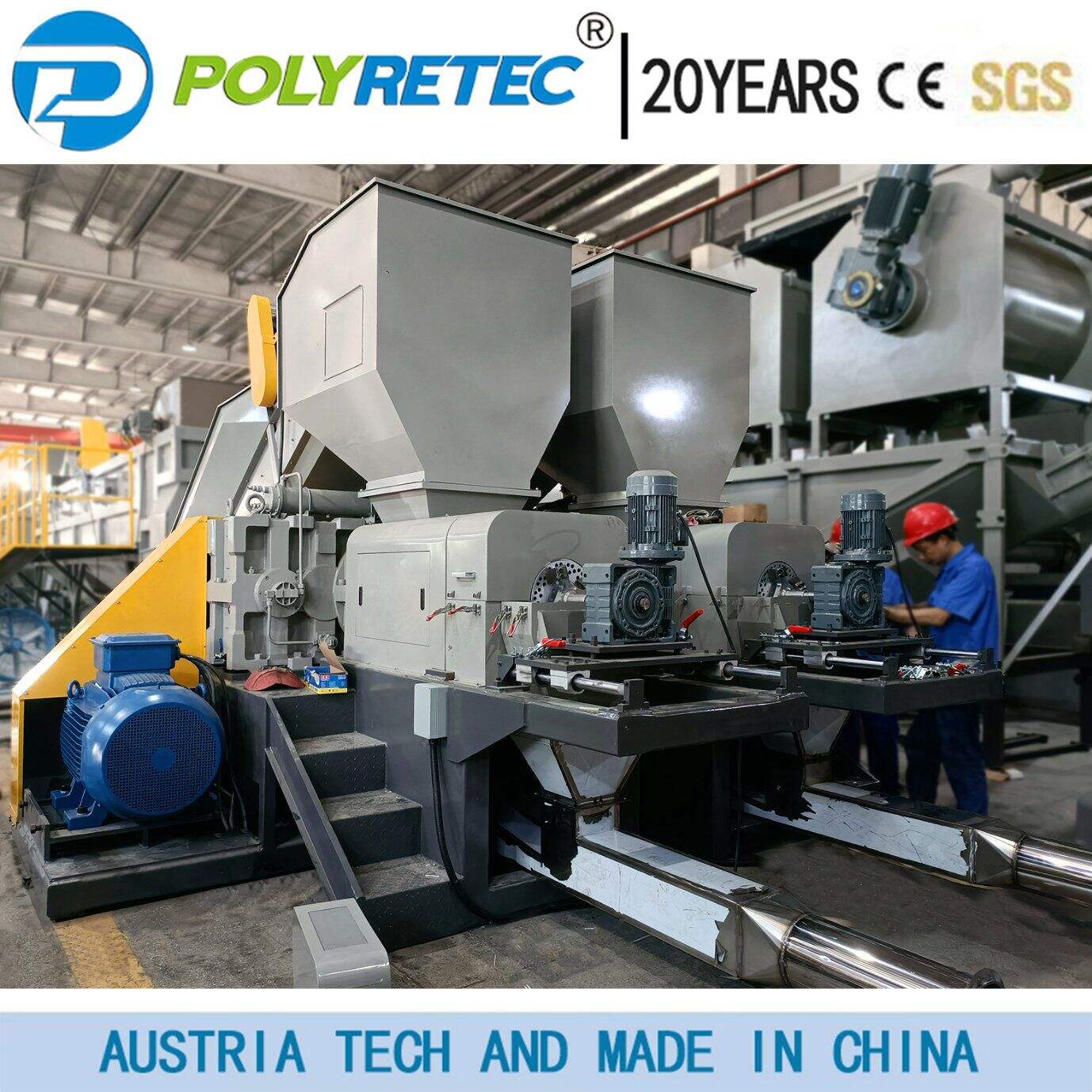

plastic scrap recycling plant

A plastic scrap recycling plant represents a comprehensive solution for transforming waste plastic materials into valuable resources through an advanced mechanical and chemical process. The facility incorporates state-of-the-art sorting systems, washing units, grinding mechanisms, and extrusion equipment to process various types of plastic waste efficiently. The plant's primary functions include the reception and sorting of mixed plastic waste, contamination removal through intensive washing, size reduction through grinding, and finally, the conversion of processed material into recycled plastic pellets. Advanced sensor-based sorting technology ensures high purity levels in the final output, while automated control systems maintain consistent quality throughout the process. The plant can handle multiple plastic types, including PET, HDPE, LDPE, and PP, with specialized processing lines for each material category. Modern plants feature energy-efficient systems that minimize operational costs while maximizing throughput capacity. The facility's modular design allows for easy scaling and maintenance, ensuring long-term operational reliability. With processing capacities ranging from 500 kg to several tons per hour, these plants serve various industrial needs while contributing to environmental sustainability through reduced landfill waste and lower carbon emissions.