bottle washing plant

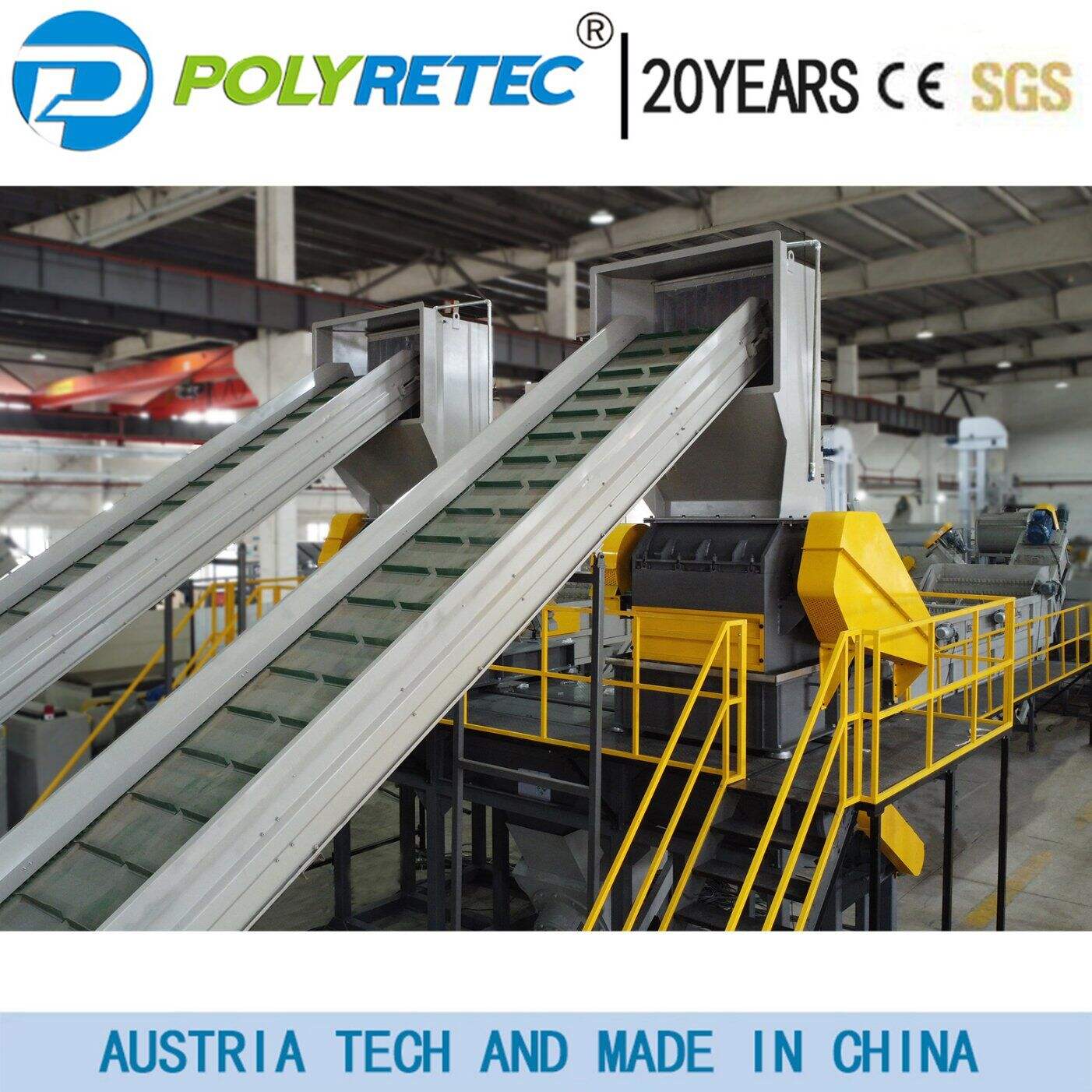

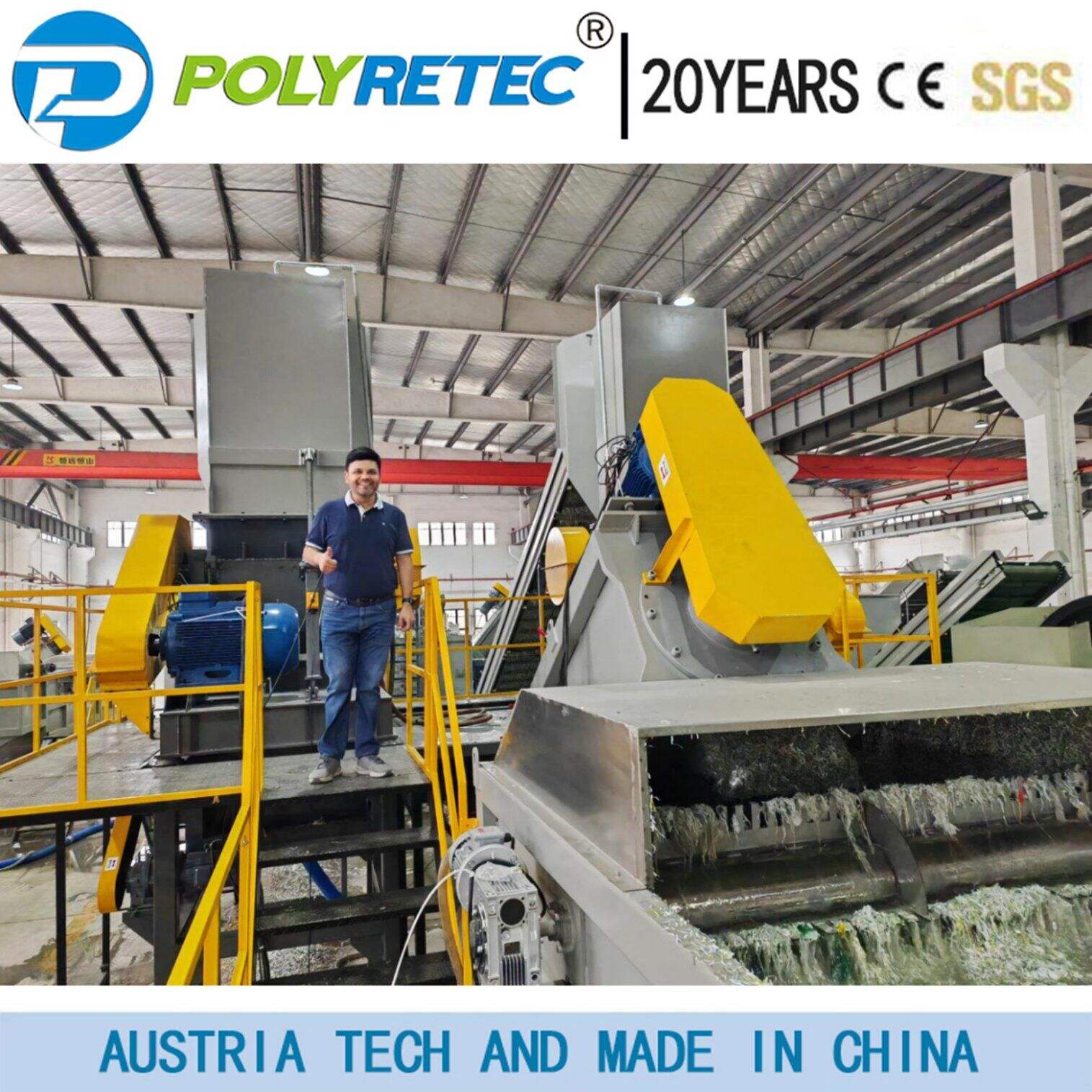

A bottle washing plant is an advanced industrial system designed to clean and sanitize various types of bottles efficiently and thoroughly before they enter the filling process. This sophisticated machinery combines multiple cleaning stages, including pre-washing, main washing, and rinsing phases, ensuring bottles meet stringent hygiene standards. The plant utilizes a combination of mechanical and chemical cleaning processes, incorporating high-pressure water jets, specialized detergents, and precise temperature control systems. Modern bottle washing plants are equipped with automated conveyor systems that transport bottles through different cleaning zones, maintaining consistent cleaning quality while maximizing throughput. The technology includes advanced sensors for monitoring water quality, temperature, and chemical concentration levels, ensuring optimal cleaning performance. These plants are capable of handling different bottle sizes and materials, from glass to PET, with adjustable parameters to suit specific cleaning requirements. The system also features water recycling capabilities, reducing environmental impact while maintaining cost-effectiveness. Safety features include emergency shutdown systems, overflow protection, and automated chemical dosing controls. The plant's design emphasizes efficiency in both energy consumption and water usage, making it an environmentally responsible choice for beverage manufacturers.