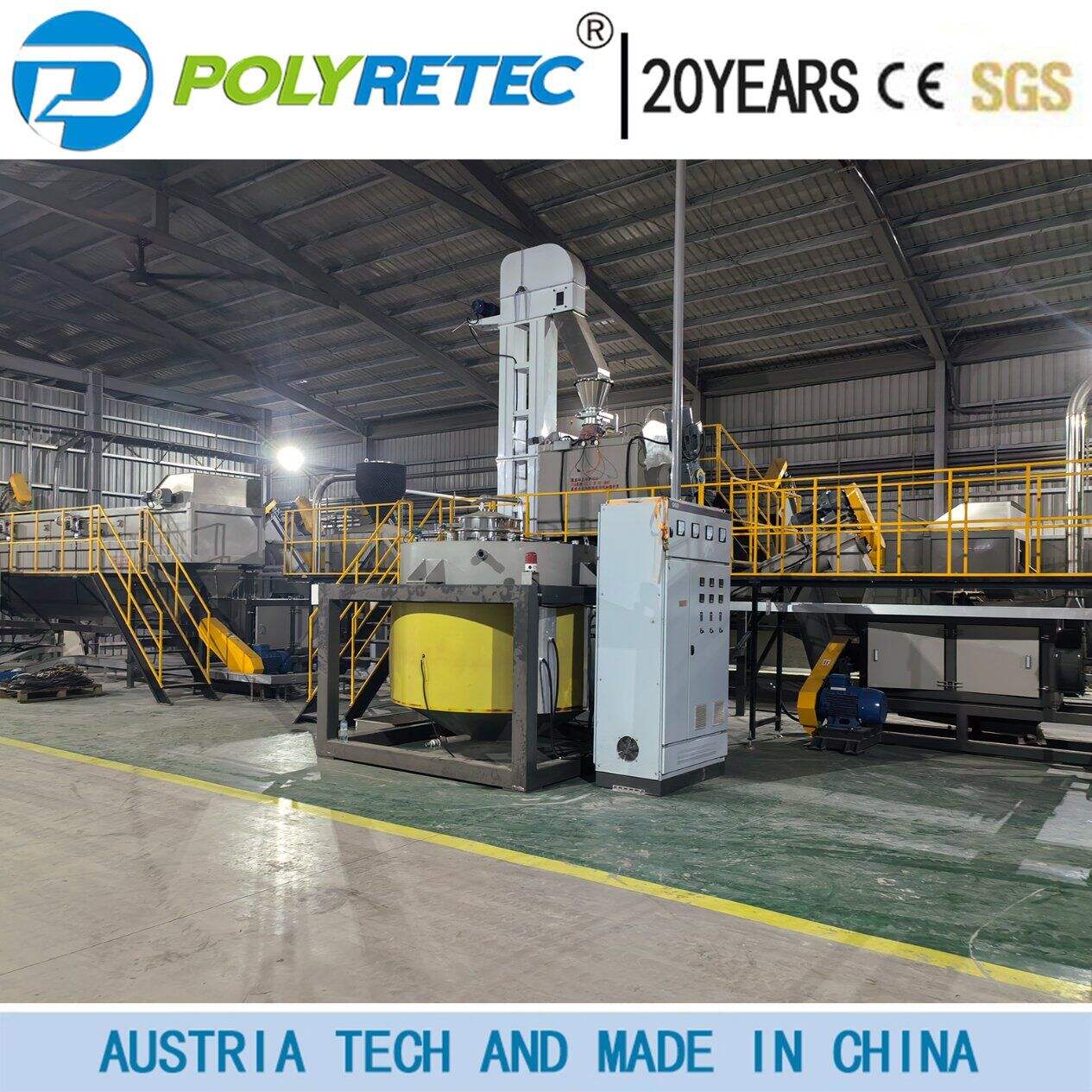

granulator plastic recycling

Granulator plastic recycling represents a crucial advancement in sustainable waste management, offering an efficient solution for processing various plastic materials. This sophisticated system employs cutting-edge technology to transform plastic waste into uniform, reusable granules through a precise mechanical process. The granulator consists of a robust cutting chamber equipped with rotating blades that work against stationary knives, effectively reducing plastic materials to consistent sizes. The machine's innovative design allows for processing different types of plastics, from rigid materials to softer variants, making it versatile for various industrial applications. The system incorporates advanced screening mechanisms to ensure uniform particle size and includes sophisticated control systems for operational efficiency and safety. Modern granulators feature adjustable cutting speeds, variable rotor configurations, and automated feeding systems, enabling customized processing for different plastic types. The technology also includes dust collection systems and noise reduction features, making it environmentally friendly and workplace-compliant. These machines are essential in both post-industrial and post-consumer plastic recycling, contributing significantly to circular economy initiatives and sustainable manufacturing practices.