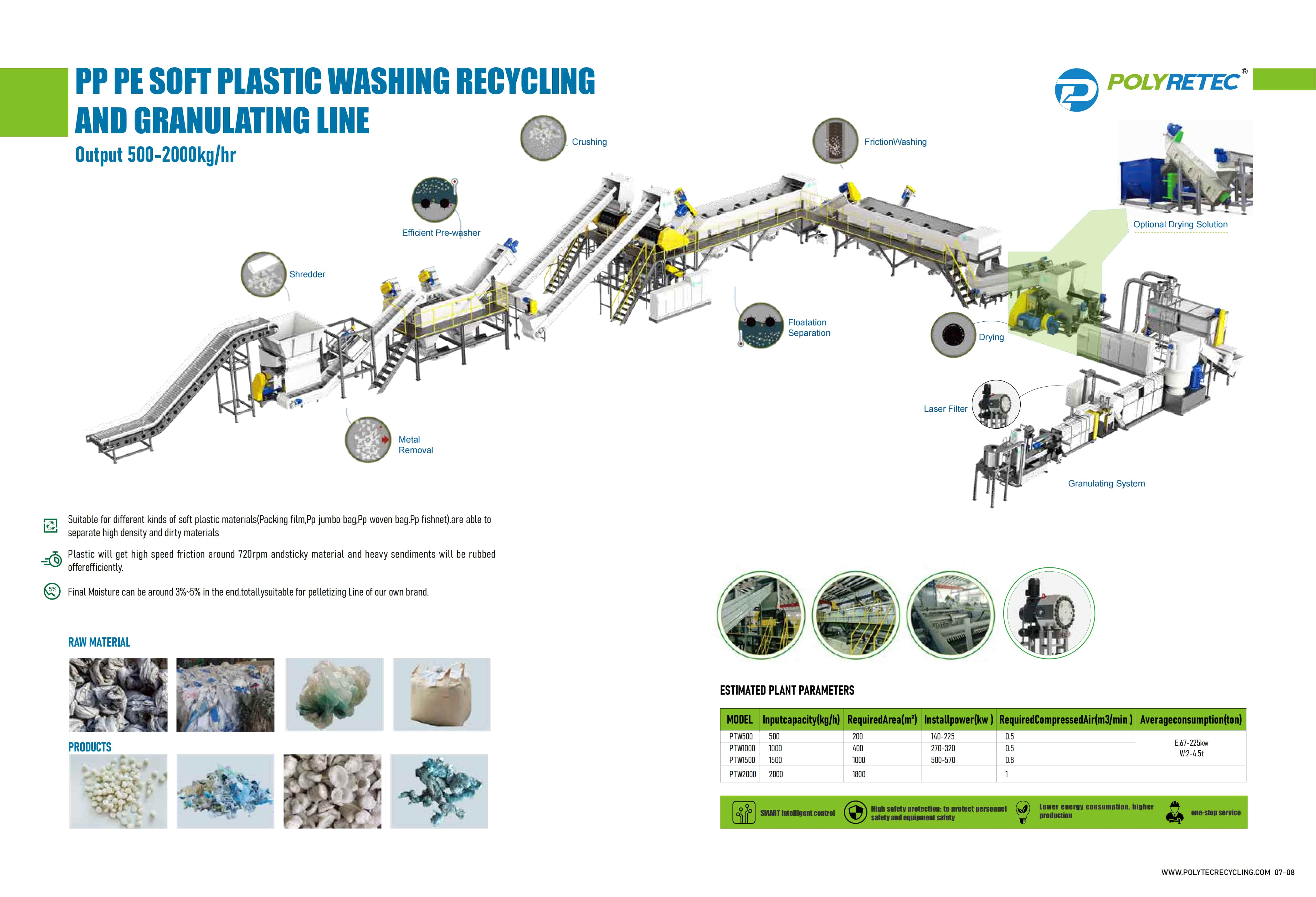

Raw materials: Agricultural film, Post-consumer film, Post-commercial and post-industrial film, jumbo bag, PP woven bag, etc.

| Model | Input capacity (kg/h) |

Required Area (m2) |

Installation power (KW) |

Required compressed air (m3/min) |

Average consumption (ton) |

| PTW500 | 500 | 200 | 140-225 | 0.5 | E: 67-225kw W: 2-6.5t |

| PTW1000 | 1000 | 400 | 270-320 | 0.5 | |

| PTW1500 | 1500 | 1000 | 500-570 | 0.8 | |

| PTW2000 | 2000 | 1800 | 1 |

| NO. | Machine | Parameter | Picture |

| 1. | Metal-chain conveyor |

Usage:for conveying baled material into next step |  |

| 2. | Pre- Shredder |

Usage :Designed for materials with high strength, toughness, and high sediment content, it can cut the entire package of materials to a relatively uniform size and allowing the thin film materials to be fully unfolded for cleaning and drying. |

|

| 3. | Belt conveyor | Usage:for conveying material into next step and removing steels. |  |

| 4. | Pre-washer | Usage :for remove sands ,stone,steel by high speed friction and rinsing washer in one . Comprising of: The separation tank,built in stainless steel Discharge drum Double discharge system for "heavies",500x500 mm square,motorized valves With pneumatic water in-feed-valve,automatic level control via electronic feeler. With compressor blower to inject compressed air to the bottom of the tank. With working platform. |

|

| 5. | PC wet crusher | Usage:for wet crushing the material into smaller size |  |

| 6. | Friction washer |

Usage :rub flakes and take dirty water out in case go to next step .

|

|

| 7. | Rinsing Washing tank |

Usage: sinking and removing dirty sands stone ,oil,dust ,etc

|

|

| 8. | Squeezer Dryer |

Eventually semimyzing with water content of less than 5%

|

|

| 8.1 | Mechanical dryer MMD XL (optional drying solution) |

Usage: Drying and removing water. Advantages: High effective drying and cleaning Reinforced,mild steel and high speed rotor with exchangeable padels Stainless steel screen hole size 2-3mm in polygon version for higher washing/drying effect Easy replacement of screens(segmental design) Housing builtin mild steel,welded construction Oversized,outside mountedbearings Easy maintenance |

|

| 8.2 | Thermal dryer MTD120& Blower MDB55-500 (optional drying solution) |

Usage: for drying flakes For final drying of the flakes to a moisture of about 2 - 5 % by weight comprising of: - mixing chamber for mixing the product with hot air, - heating device - drying spiral with about 20 m length build in compact version, - material separating cyclone, - temperature control device |

|

| 9 | Storage silo | Usage :for temporary storage for flakes. Blower power:5.5kw Volume: 5m³ Discharging by double screw |

|

| 10 | Smart Control cabinet | Use: To control the entire line. Electric elements: PLC control module : Siemens |

|