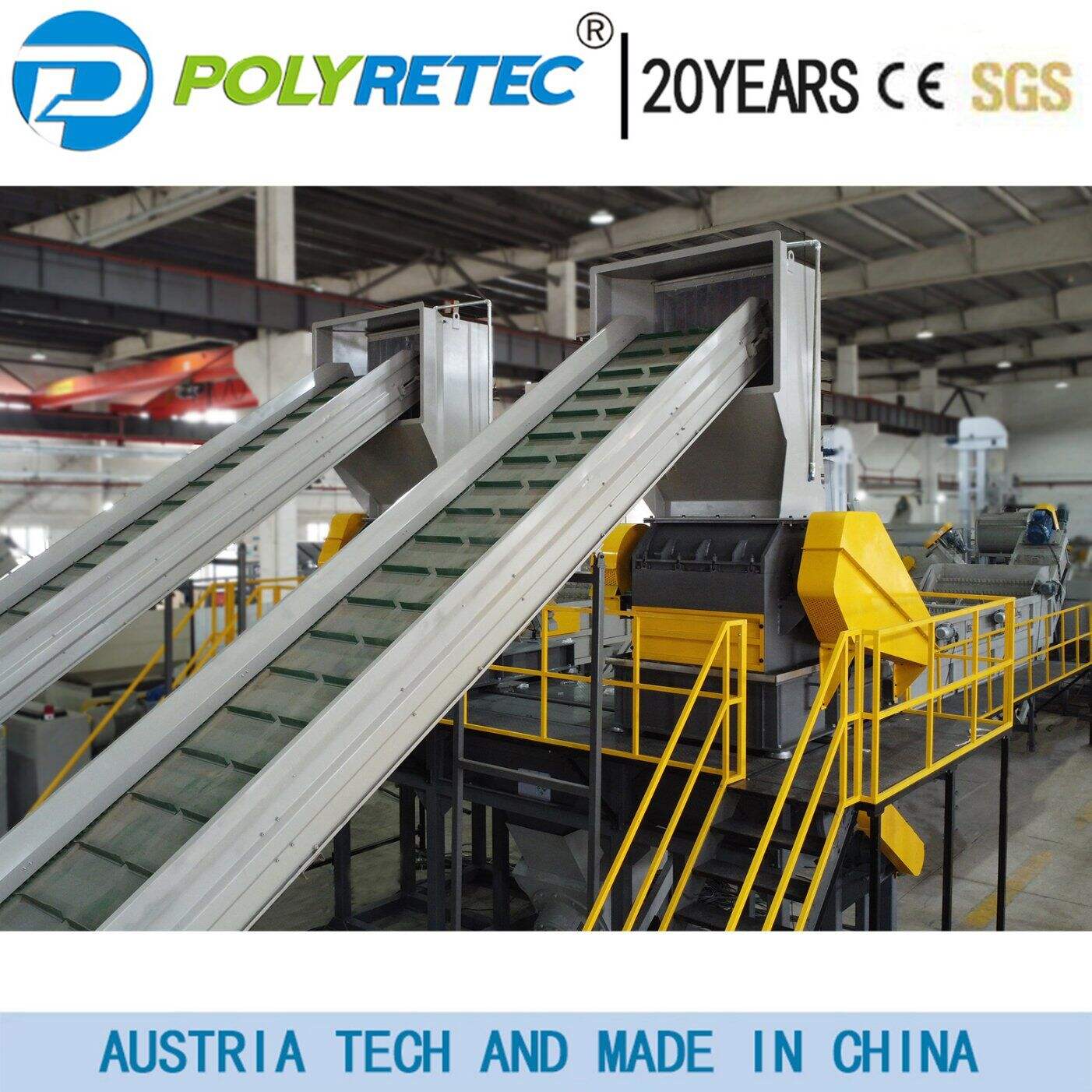

자동 PET 병 세척 공장

자동 PET 병 세척 시설은 효율적인 병 재활용 및 청소 작업을위한 최첨단 솔루션을 나타냅니다. 이 첨단 시스템은 사용 된 PET 병을 깨끗하고 재사용 가능한 재료로 변환하기 위해 여러 단계의 세척과 가공을 포함합니다. 식물은 오염물질을 제거하고 색깔과 크기로 병을 분리하는 분류 메커니즘을 사용한다. 그 후 병은 라벨과 초기 더럽을 제거하는 사전 세척 단계로 통과합니다. 주요 세척 과정은 뜨거운 촉매 용액을 고압 분사기와 결합하여 병을 철저히 청소합니다. 첨단 마찰 세척 기술은 고집한 잔류와 접착제를 제거 할 수 있습니다. 이 시스템은 남은 화학물질을 제거하기 위해 신선한 물로 여러 차례 씻어내는 것을 포함한다. 주요 기술 특징은 자동 컨베이어 시스템으로 최소한의 수동 개입으로 연속적인 작동을 보장합니다. 이 공장 은 또한 품질 통제, 온도, 화학 농도, 물 품질 등 매개 변수 모니터링을 위한 첨단 센서를 탑재 하고 있다. 마지막 단계 는 깨끗 한 병 을 더 이상 처리 하기 위해 준비 하는 건조 시스템 을 포함한다. 이 공장 은 재활용 시설, 음료 제조 공장, 산업 청소 작업 등에서 사용되며, 일정한 품질 기준을 유지하면서 시간당 수천 개의 병을 처리 합니다.