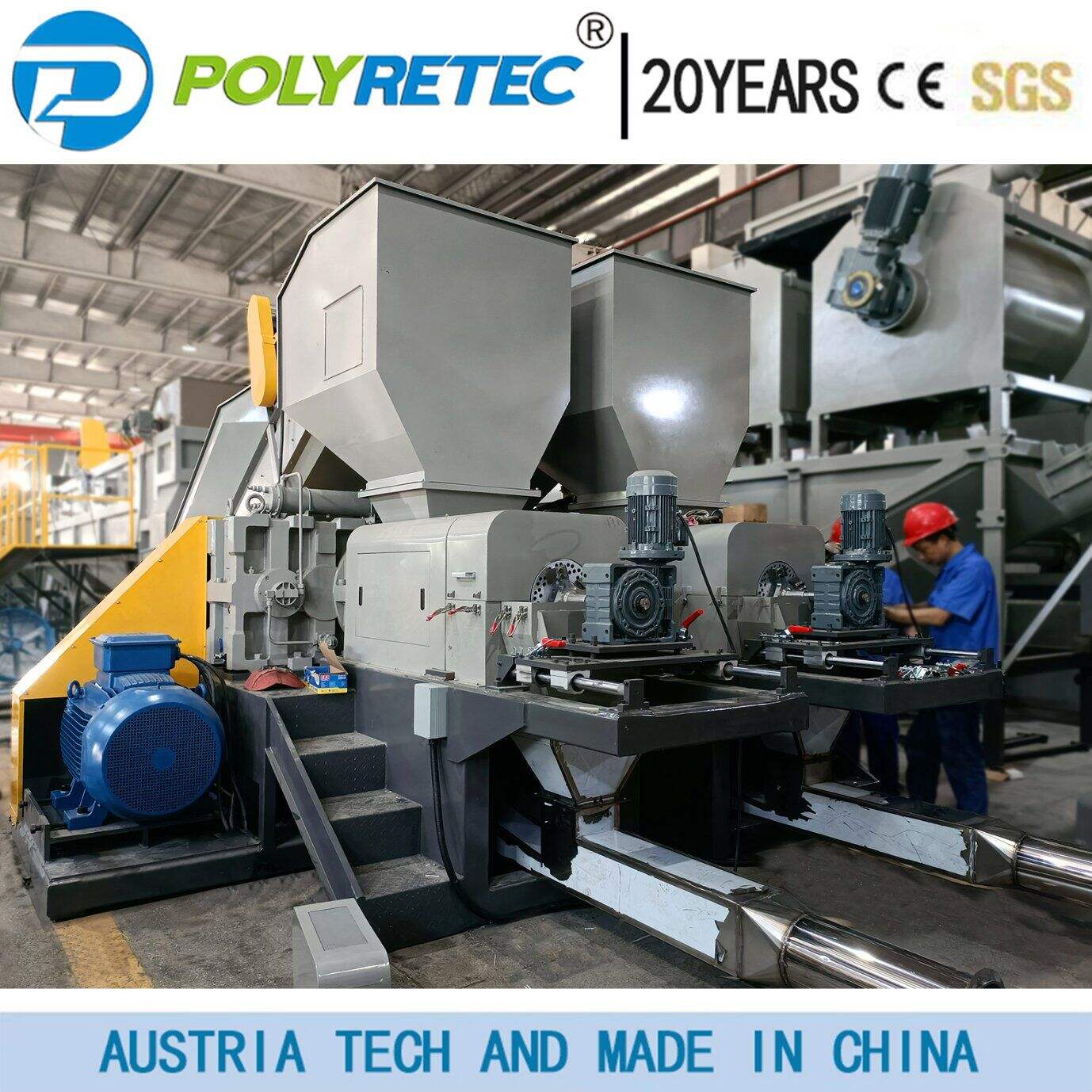

완전한 PET 병 세척 라인

완벽한 PET 병 세척 라인은 사용된 플라스틱 병을 깨끗하고 재사용 가능한 PET 플레이크로 변환하도록 설계된 정교한 재활용 시스템을 의미합니다. 이 종합적인 시스템은 PET가 아닌 물질과 오염 물질을 제거하는 분류 메커니즘을 시작으로 여러 단계의 처리 과정을 포함합니다. 이 라인은 일반적으로 벨트 컨베이어를 통해 병을 라벨 제거기 및 예비 세척 장치로 이송하는 것으로 시작하며, 여기서 초기 잔여물과 라벨이 분리됩니다. 그런 다음, 병은 고효율 세척 탱크에서 고온 세척을 거치며, 특수 세제와 기계적 교반을 통해 잘 지워지지 않는 먼지와 접착제를 제거합니다. 본 세척 후, 잔여 세제 잔여물을 제거하기 위해 깨끗한 물을 사용하는 여러 단계의 헹굼 과정을 거칩니다. 마찰 세척기는 추가적인 세척을 제공하고, 부유 탱크는 밀도에 따라 PET와 다른 물질을 분리합니다. 이 시스템에는 최종 제품의 수분 함량을 최적화하는 첨단 건조 장비가 포함되어 있습니다. 라인 전체의 품질 관리 지점은 세척 과정을 모니터링하고, 자동화 시스템은 최대 효율을 위해 매개변수를 조정합니다. 최종 생산물은 적절한 오염 제거 공정과 결합될 경우 식품 등급 포장재를 포함한 다양한 재활용 용도에 적합한 깨끗한 PET 플레이크로 구성됩니다. 전체 시스템은 일관된 품질을 유지하고 교차 오염을 방지하기 위한 안전 장치를 갖추고 있어 지속적인 작동이 가능하도록 설계되었습니다.