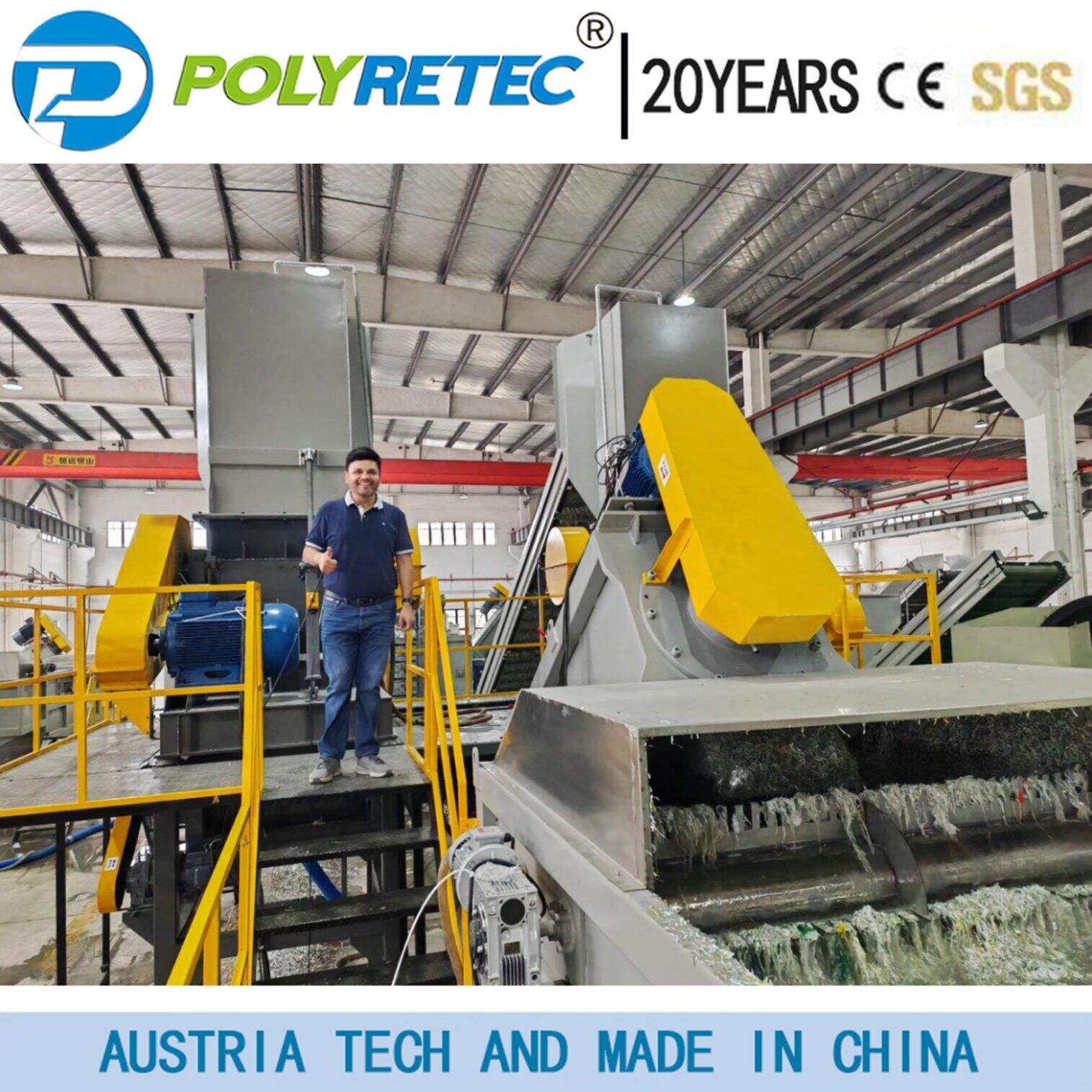

pp film recycling machine

The PP film recycling machine represents a cutting-edge solution for processing and recovering polypropylene film waste. This advanced system incorporates multiple stages of processing, including sorting, crushing, washing, drying, and pelletizing, to transform waste PP film into high-quality recycled pellets. The machine features precision-engineered components, including a powerful crusher, efficient washing system, and high-performance screw extruder, ensuring consistent output quality. The automated control system maintains optimal operating parameters throughout the recycling process, while the integrated filtration system removes contaminants effectively. With processing capabilities ranging from 300-1000 kg/hour, depending on the model, these machines accommodate various production scales. The system's modular design allows for customization based on specific requirements, whether processing post-industrial or post-consumer PP film waste. The technology employs advanced heating and cooling systems to ensure proper material transformation, while the pelletizing unit creates uniform, high-quality recycled pellets suitable for various manufacturing applications. Safety features include emergency stop systems, overload protection, and temperature monitoring, ensuring reliable and secure operation.