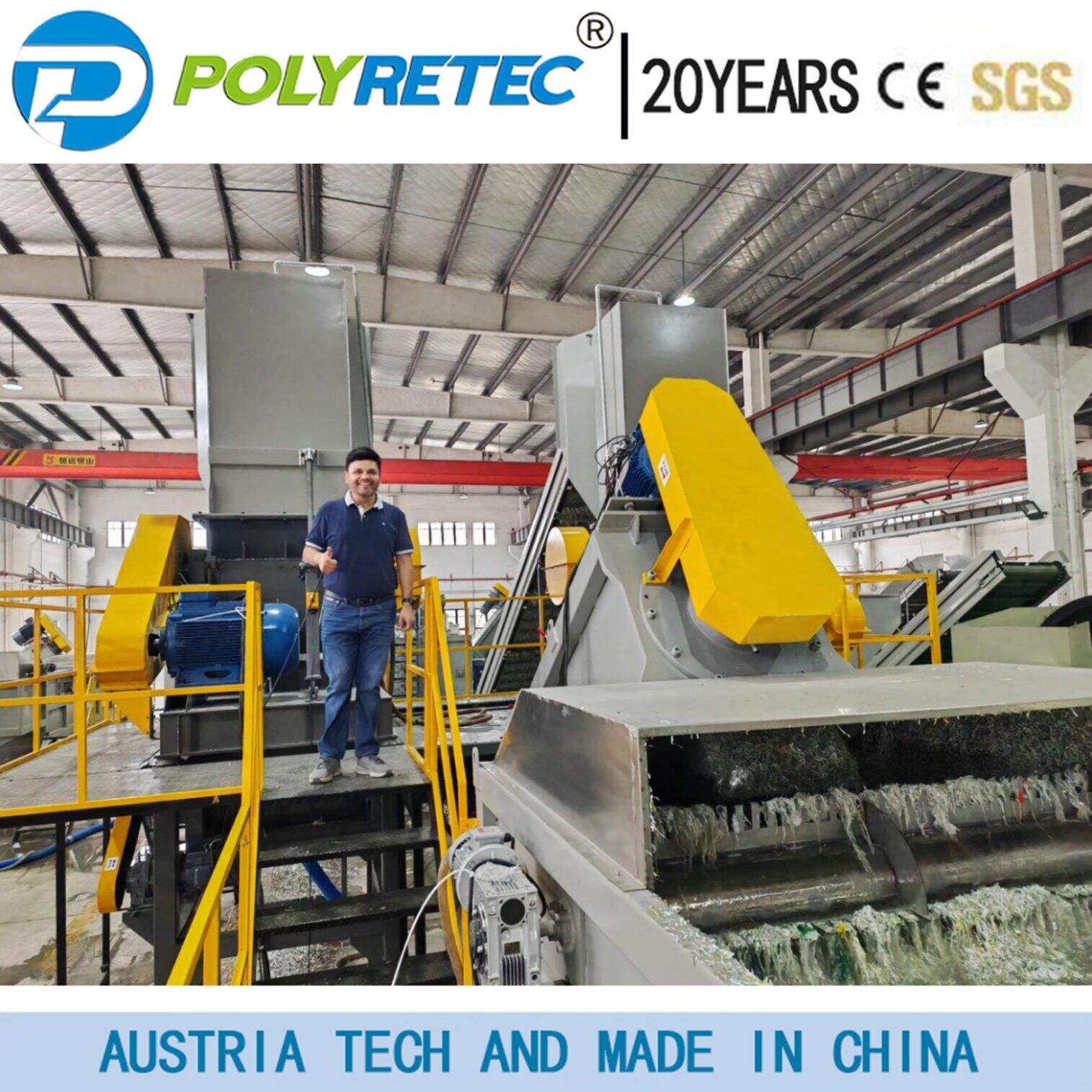

pe film recycling machine

The PE film recycling machine represents a cutting-edge solution for processing and recycling polyethylene film waste. This advanced system combines mechanical and thermal processes to transform used PE film into high-quality recycled pellets. The machine features a comprehensive processing line that begins with a powerful shredding mechanism, capable of reducing various sizes of PE film into uniform pieces. Following the initial size reduction, the material undergoes thorough washing and drying stages, ensuring the removal of contaminants and moisture. The heart of the system lies in its advanced extrusion technology, where the processed material is melted and homogenized under precise temperature control. The machine incorporates automatic screen changers and degassing systems to maintain consistent output quality. With processing capacities ranging from 300 to 1000 kg per hour, depending on the model, these machines are designed for continuous operation in industrial settings. The system's intelligent control panel allows for real-time monitoring and adjustment of operational parameters, ensuring optimal performance and energy efficiency. The final product emerges as high-quality recycled PE pellets, suitable for various manufacturing applications.