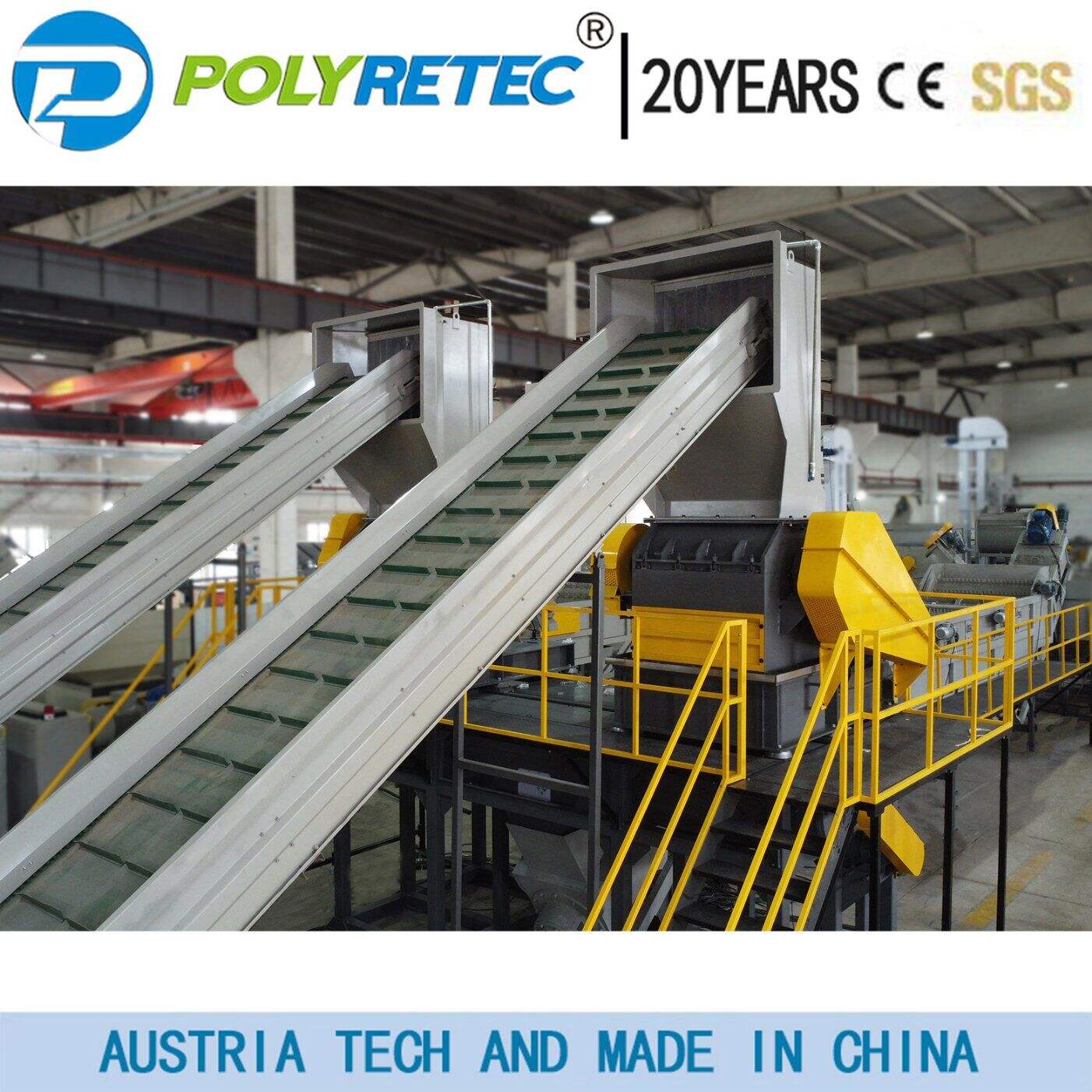

waste film recycling line

A waste film recycling line represents a comprehensive solution for processing and reclaiming various types of plastic films, transforming them into valuable recycled materials. This advanced system incorporates multiple stages of processing, beginning with a powerful shredding mechanism that reduces waste film into manageable sizes. The material then undergoes thorough washing and drying processes, eliminating contaminants and preparing it for further processing. A key feature is the advanced sorting system that separates different types of films based on their composition, ensuring higher quality output. The line includes sophisticated melting and pelletizing equipment that transforms the processed material into uniform, high-quality pellets suitable for reuse in manufacturing. Modern waste film recycling lines are equipped with automated control systems that monitor and adjust processing parameters in real-time, ensuring consistent output quality. The system's modular design allows for customization based on specific capacity requirements and material types, making it adaptable to various industrial needs. Environmental protection measures, including dust collection and water treatment systems, are integrated to minimize environmental impact during operation.