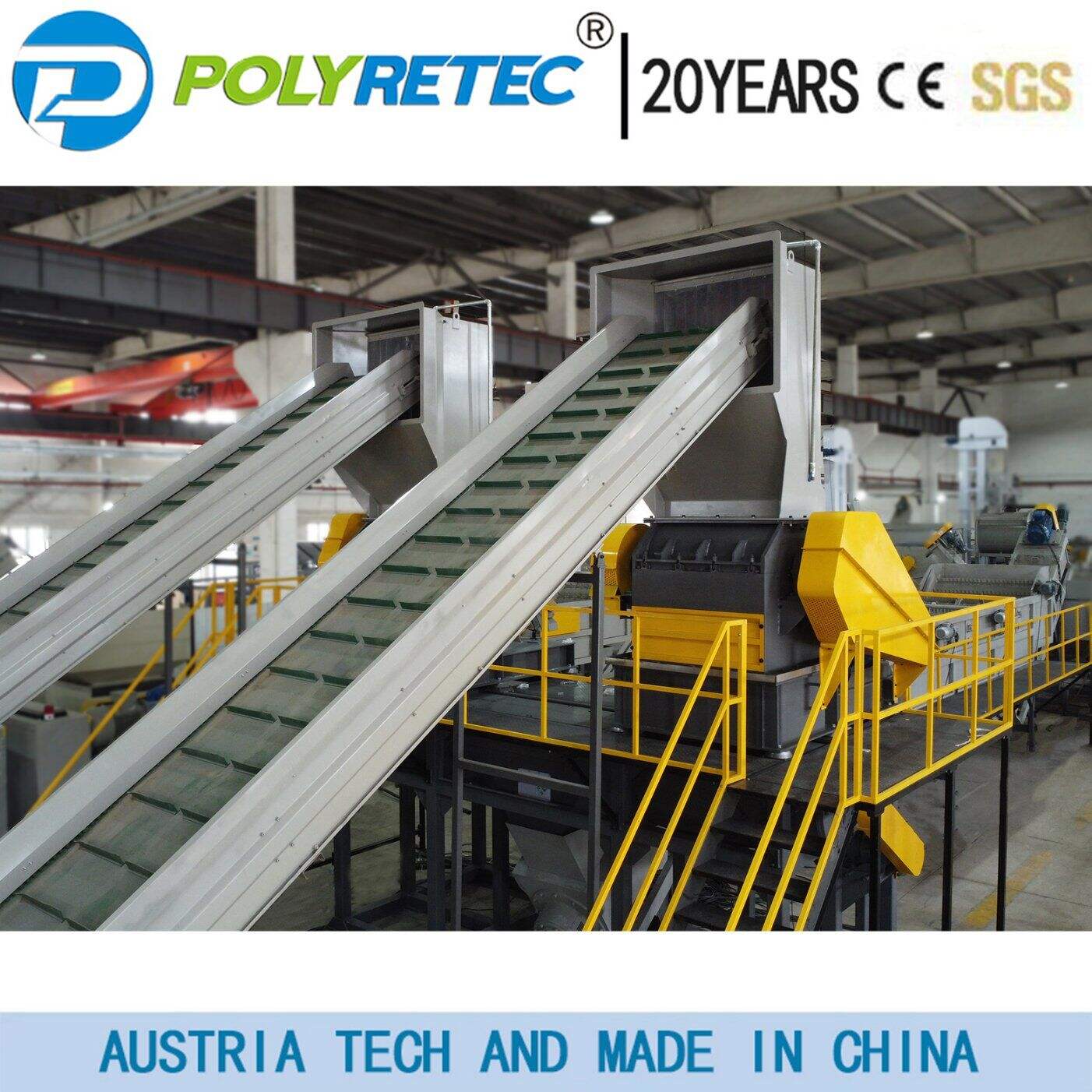

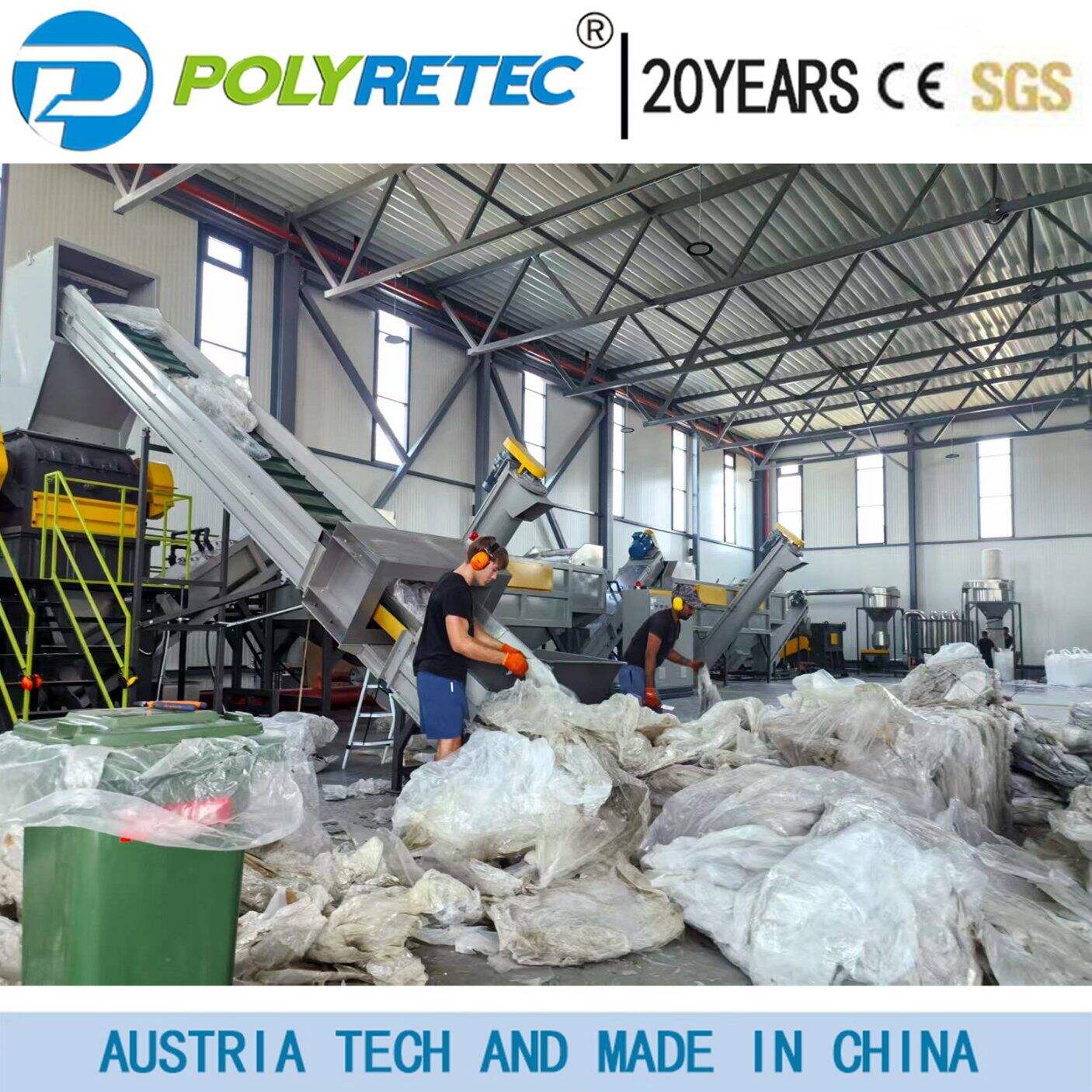

plastic waste recycling system

A plastic waste recycling system is an integrated solution designed to transform plastic waste into valuable resources through a series of sophisticated processes. The system typically begins with a sorting mechanism that utilizes advanced sensors and artificial intelligence to separate different types of plastics based on their composition. This initial stage ensures optimal processing efficiency and output quality. The core of the system features a multi-stage cleaning process that removes contaminants, labels, and adhesives, followed by a size reduction phase where the plastic is shredded into uniform pieces. These pieces then undergo a washing and drying cycle before entering the melting and extrusion phase. The system employs precise temperature control and specialized equipment to convert the processed plastic into pellets or flakes suitable for manufacturing new products. Modern plastic waste recycling systems also incorporate real-time monitoring systems that track performance metrics, energy consumption, and output quality. The entire process is designed to be energy-efficient and environmentally sustainable, with minimal waste generation. These systems can handle various plastic types, including PET, HDPE, LDPE, and PP, making them versatile solutions for different recycling needs.