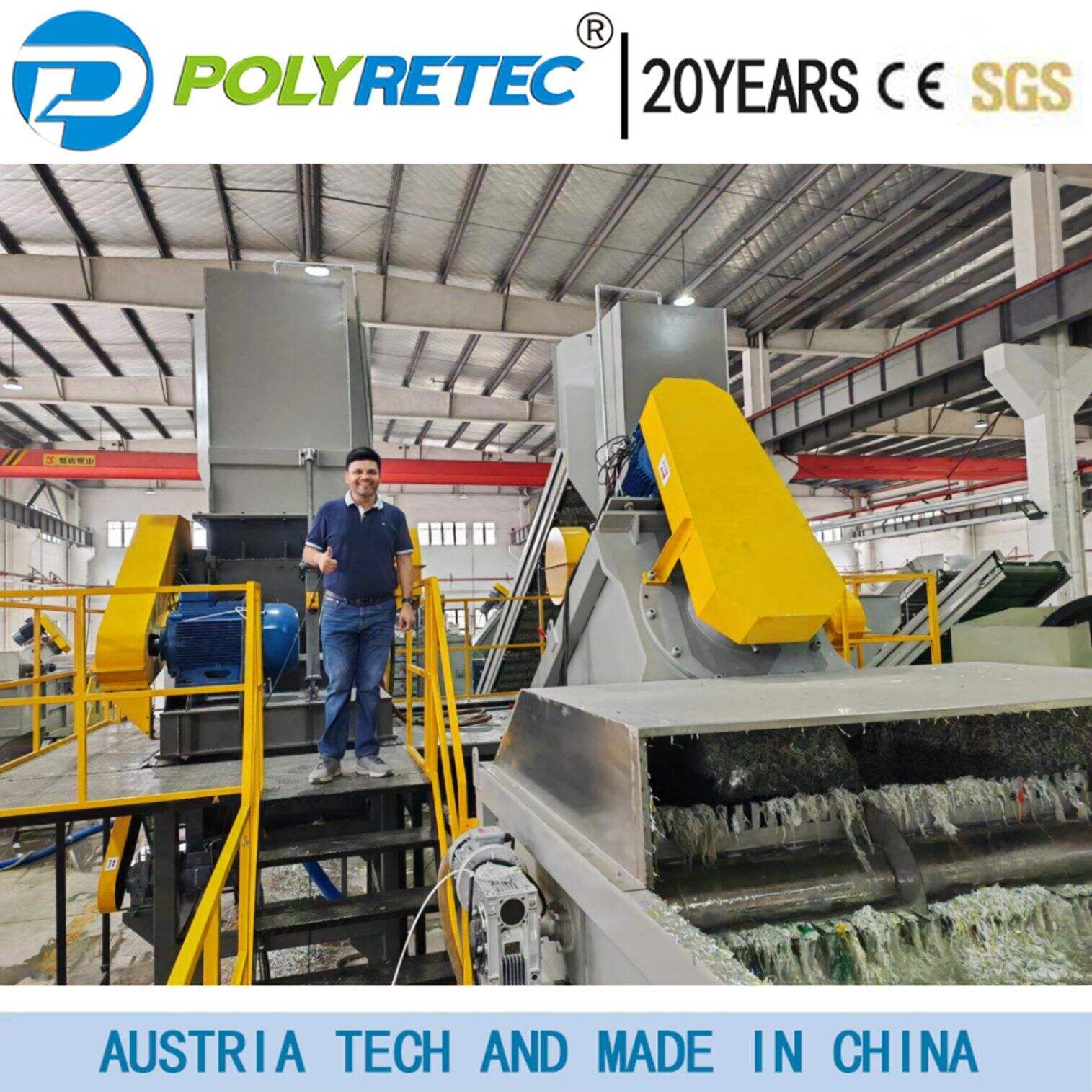

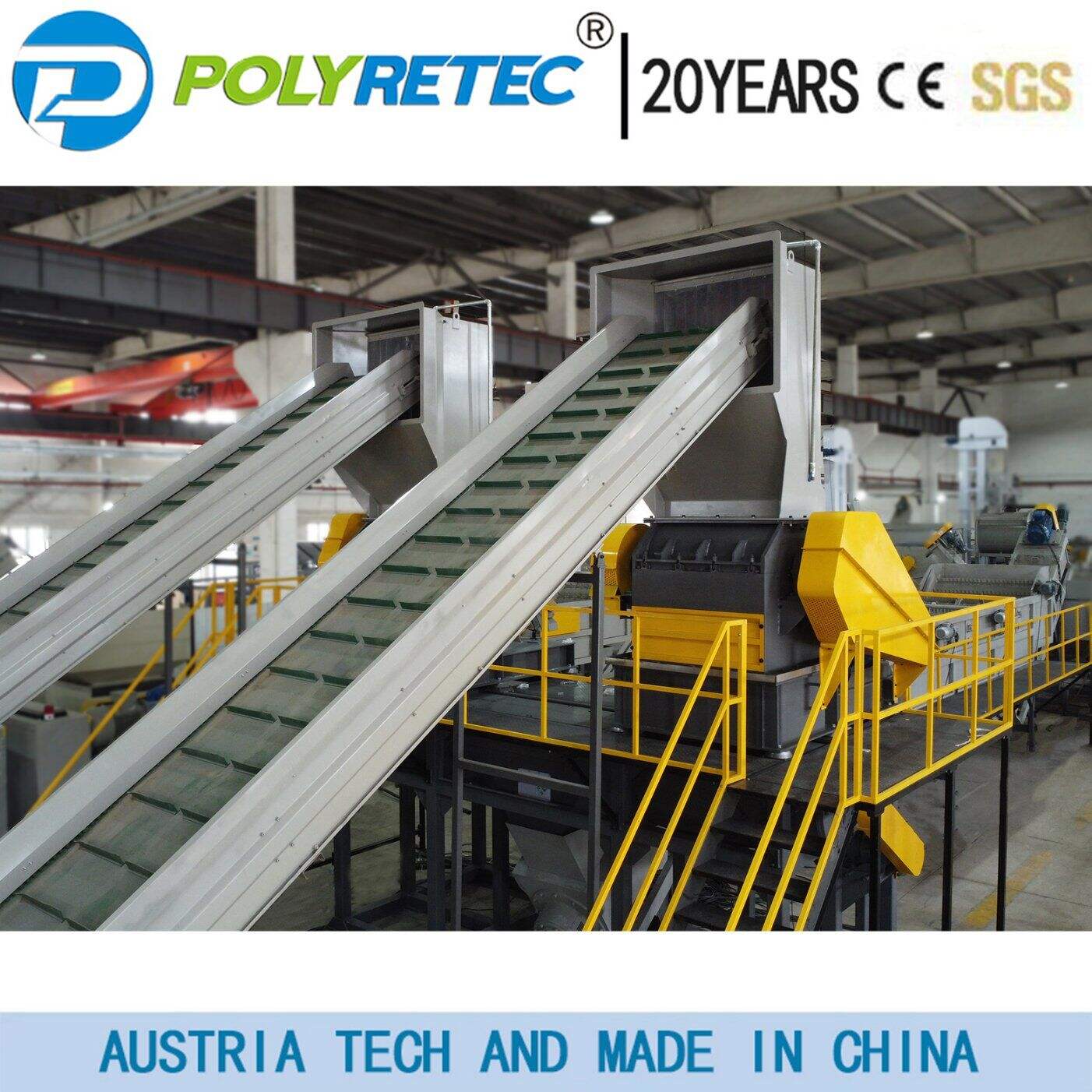

pet bottle recycling system

The PET bottle recycling system represents a cutting-edge solution for transforming used plastic bottles into valuable resources. This comprehensive system incorporates multiple stages of processing, beginning with the collection and sorting of PET bottles, followed by grinding them into flakes. The advanced washing system removes contaminants, labels, and adhesives, ensuring high-quality output. The technology employs sophisticated sensors and automated sorting mechanisms to separate different types of plastics, guaranteeing material purity. The system's heart lies in its extrusion and pelletizing units, which convert cleaned flakes into recycled PET pellets suitable for various applications. Modern PET recycling systems can process up to 3,000 kg per hour, achieving a remarkable recovery rate of 85-95%. The system's modular design allows for scalability and customization based on specific requirements. Quality control measures, including crystallization and solid-state polycondensation, ensure the final product meets food-grade standards when necessary. The entire process is monitored through advanced control systems that optimize energy consumption and maintain consistent output quality.