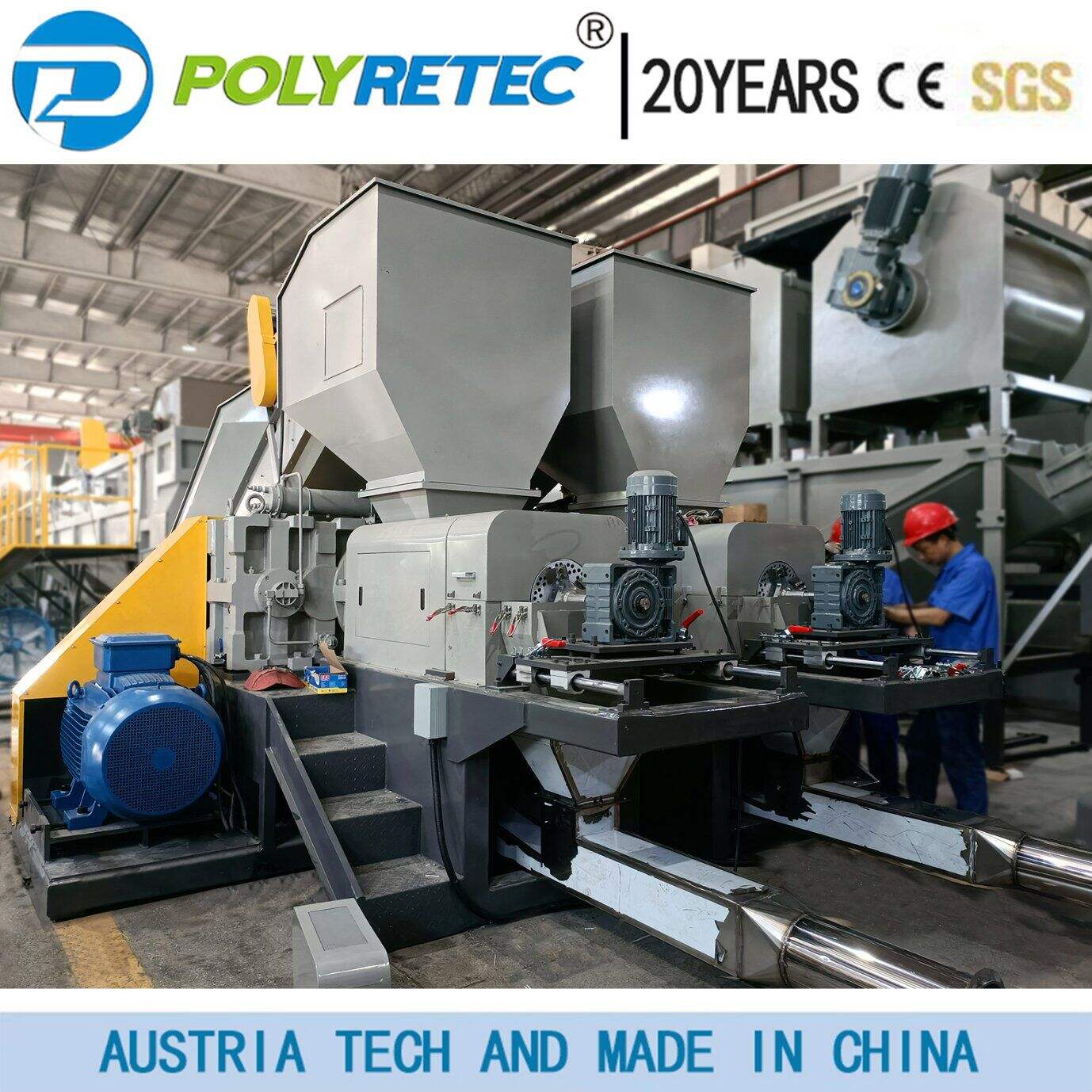

plastic pelletizer for sale

The plastic pelletizer for sale represents a cutting-edge solution in plastic recycling and manufacturing. This advanced machinery transforms plastic materials into uniform, high-quality pellets through a sophisticated process of melting, extruding, and cooling. The system features precision-engineered components, including a robust screw extruder, efficient heating elements, and an advanced cutting mechanism. Operating at temperatures ranging from 120 to 300 degrees Celsius, it can process various plastic materials including PE, PP, PS, and ABS. The pelletizer's intelligent control system maintains consistent pellet size and quality, while its water-cooling system ensures optimal temperature management throughout the production process. With processing capabilities of 50-500 kg per hour, depending on the model, this equipment serves diverse industrial needs. The machine incorporates safety features such as emergency shutdown systems and overload protection, ensuring reliable and secure operation. Its modular design facilitates easy maintenance and cleaning, while the stainless steel construction guarantees durability and longevity. The pelletizer's versatility makes it ideal for plastic recycling facilities, manufacturing plants, and material processing centers looking to optimize their production capabilities.