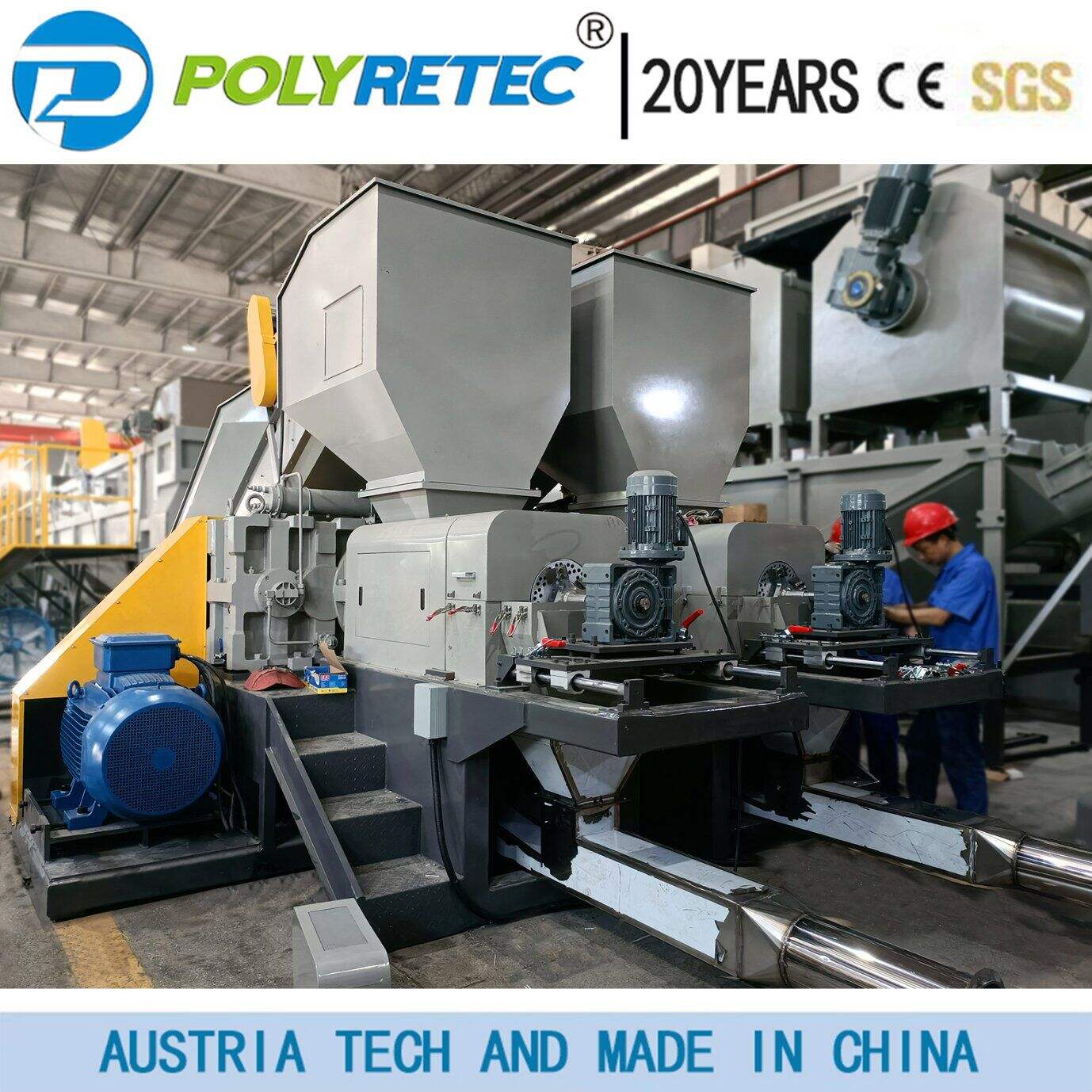

plastic flakes recycling machine

The plastic flakes recycling machine represents a cutting-edge solution in waste management technology, designed to process and transform plastic waste into valuable, reusable materials. This sophisticated equipment employs a multi-stage process that begins with the thorough cleaning of plastic flakes, removing contaminants and ensuring optimal quality for recycling. The machine features advanced sorting mechanisms that can separate different types of plastics based on their composition and color, ensuring high-quality output. Its robust grinding system reduces plastic materials to uniform-sized flakes, while the washing and drying components ensure the final product meets industry standards. The machine's automated control system maintains consistent operation parameters, monitoring temperature, pressure, and processing speed to achieve optimal results. With processing capacities ranging from 500 to 3000 kg per hour, these machines can handle various types of plastics, including PET, HDPE, and PP. The integrated filtration system removes impurities and ensures the final product meets stringent quality requirements. This versatile equipment finds applications across various industries, from packaging manufacturing to textile production, making it an essential tool in modern recycling facilities.