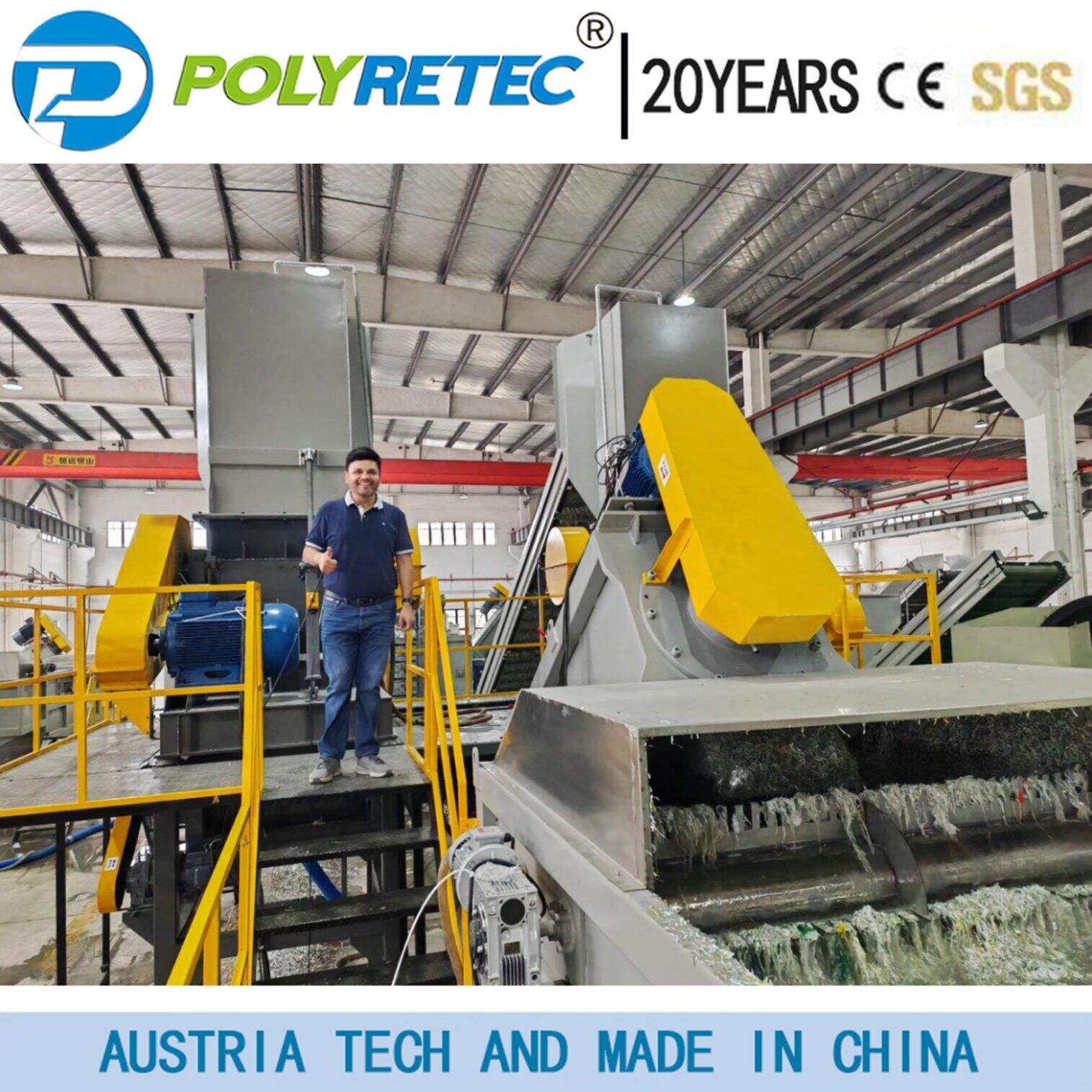

polyester recycling machine

The polyester recycling machine represents a cutting-edge solution in sustainable textile processing, designed to transform post-consumer and post-industrial polyester waste into reusable raw materials. This innovative system employs advanced mechanical and chemical processes to break down polyester materials into their base components while maintaining high material purity. The machine features a comprehensive processing line that includes sorting mechanisms, cutting units, washing systems, and specialized extrusion equipment. Operating at optimal temperatures of 250-300°C, it efficiently depolymerizes PET materials into bis(2-hydroxyethyl) terephthalate, which can be reprocessed into new polyester products. The system's automated controls ensure precise operation parameters, while its modular design allows for customization based on specific production requirements. With processing capabilities ranging from 500 to 2000 kg per day, the machine serves various industries, including textile manufacturing, packaging, and synthetic fiber production. Its advanced filtration system removes contaminants and ensures the final product meets industry quality standards, making it suitable for both small-scale recycling operations and large industrial applications.