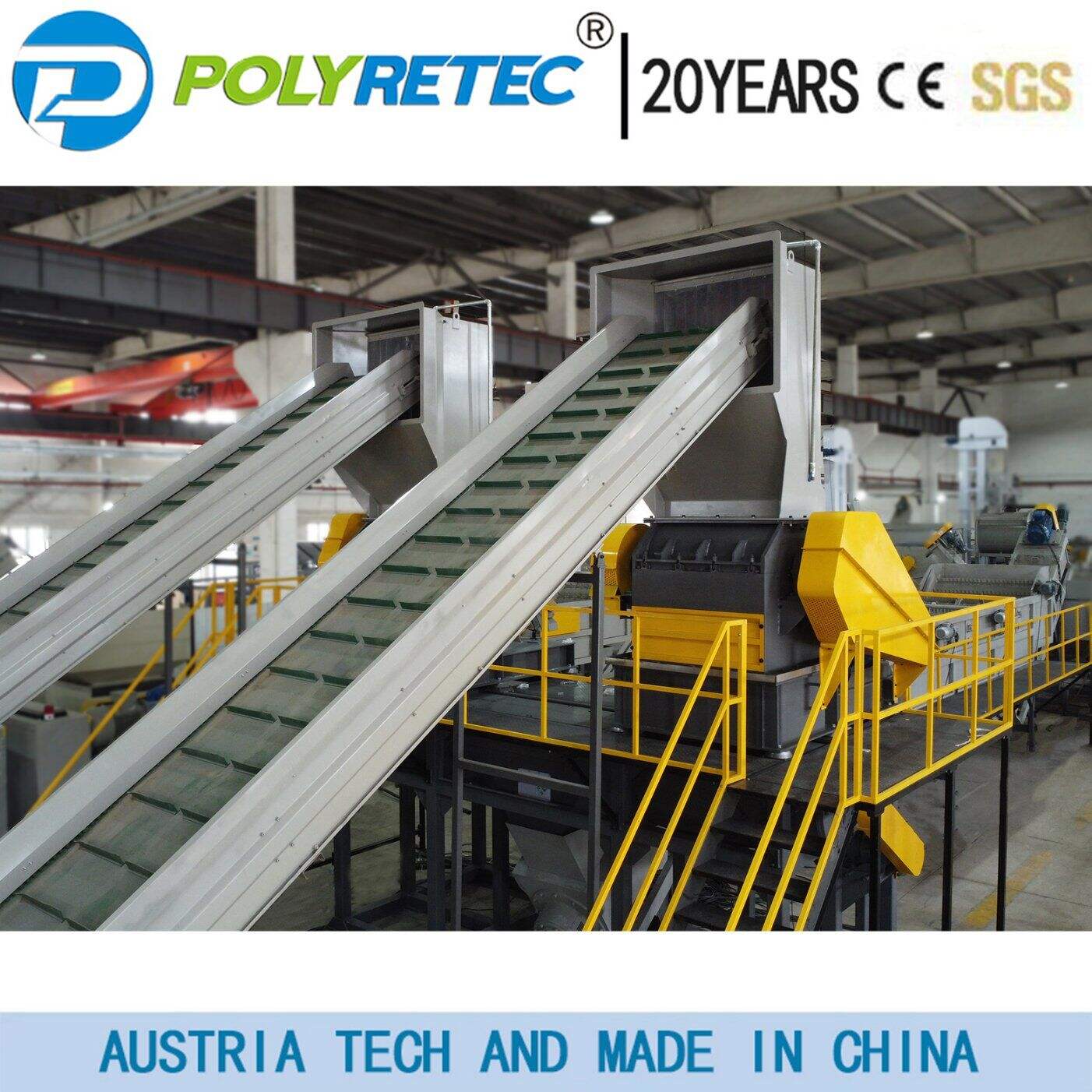

waste plastic bottle recycling machine

The waste plastic bottle recycling machine represents a cutting-edge solution for transforming used plastic bottles into valuable recycled materials. This advanced system incorporates multiple processing stages, including sorting, crushing, washing, drying, and pelletizing, all integrated into a single efficient unit. The machine can handle various types of plastic bottles, including PET, HDPE, and PP materials, with processing capacities ranging from 500 to 3000 kg per hour depending on the model. Its automated sorting system employs advanced sensors and artificial intelligence to identify and separate different types of plastics, ensuring high-quality output. The crushing mechanism features hardened steel blades that reduce bottles to uniform flakes, while the washing system removes contaminants and labels using environmentally friendly cleaning agents. The sophisticated drying system utilizes hot air circulation technology to achieve optimal moisture content, preparing the material for the final pelletizing stage. The pelletizing process transforms the cleaned flakes into uniform, high-quality plastic pellets suitable for manufacturing new products. This machine incorporates safety features such as emergency shut-off systems, overload protection, and noise reduction technology, making it both safe and operator-friendly.