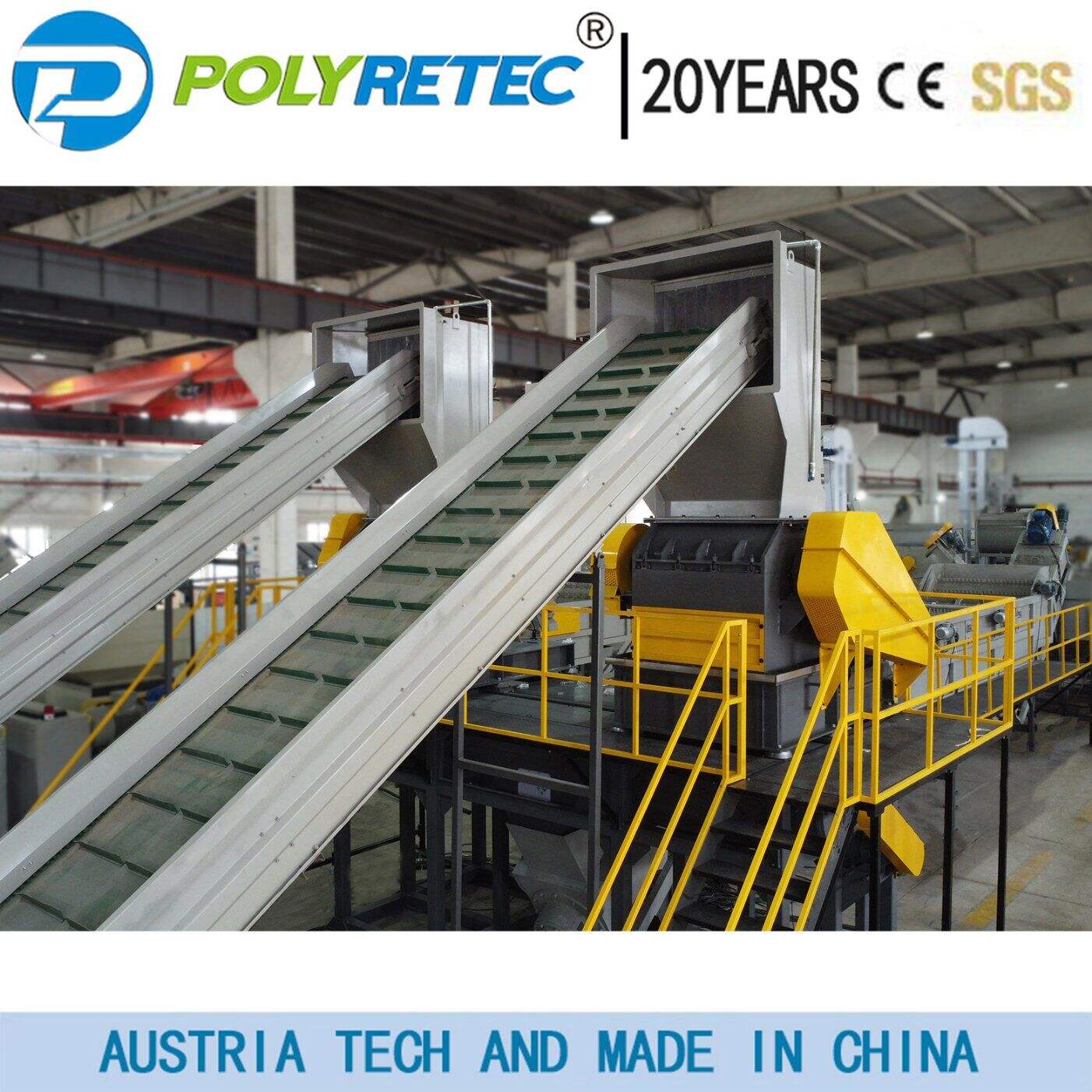

hDPE 필름 재활용 기계

HDPE 필름 재활용 기계는 고밀도 폴리에틸렌 필름 폐기물을 처리하고 회수하기 위한 첨단 솔루션을 제공합니다. 이 고도로 발달된 장비는 기계적 및 열적 공정을 결합하여 폐HDPE 필름을 고품질 재생 펠릿으로 전환시킵니다. 이 기계는 분류, 파쇄, 세척, 건조 및 펠릿화 단계로 구성된 종합적인 처리 라인을 갖추고 있습니다. 최신 분쇄 시스템은 HDPE 필름을 균일한 크기로 효과적으로 분쇄하며, 세척 시스템은 오염물질을 제거하여 소재의 순도를 보장합니다. 열융해 및 압출 구성 요소는 정밀하게 제어된 온도에서 작동하여 소재 특성을 유지합니다. 시간당 300~1000kg의 처리 능력을 갖춘 본 기계는 다양한 생산 규모에 대응할 수 있습니다. 자동 제어 시스템은 실시간으로 운전 조건을 모니터링 및 조정하여 일관된 제품 품질을 보장합니다. 이 기계의 다용도성은 농업용 필름부터 포장재에 이르기까지 다양한 두께의 HDPE 필름을 처리할 수 있게 합니다. 마모 저항성이 뛰어난 부품으로 제작된 본 기계는 장기간의 신뢰성과 최소한의 유지보수를 자랑합니다. 고효율 모터와 혁신적인 난방 시스템이 통합되어 전력 소비를 최적화하면서도 높은 생산성을 유지합니다.