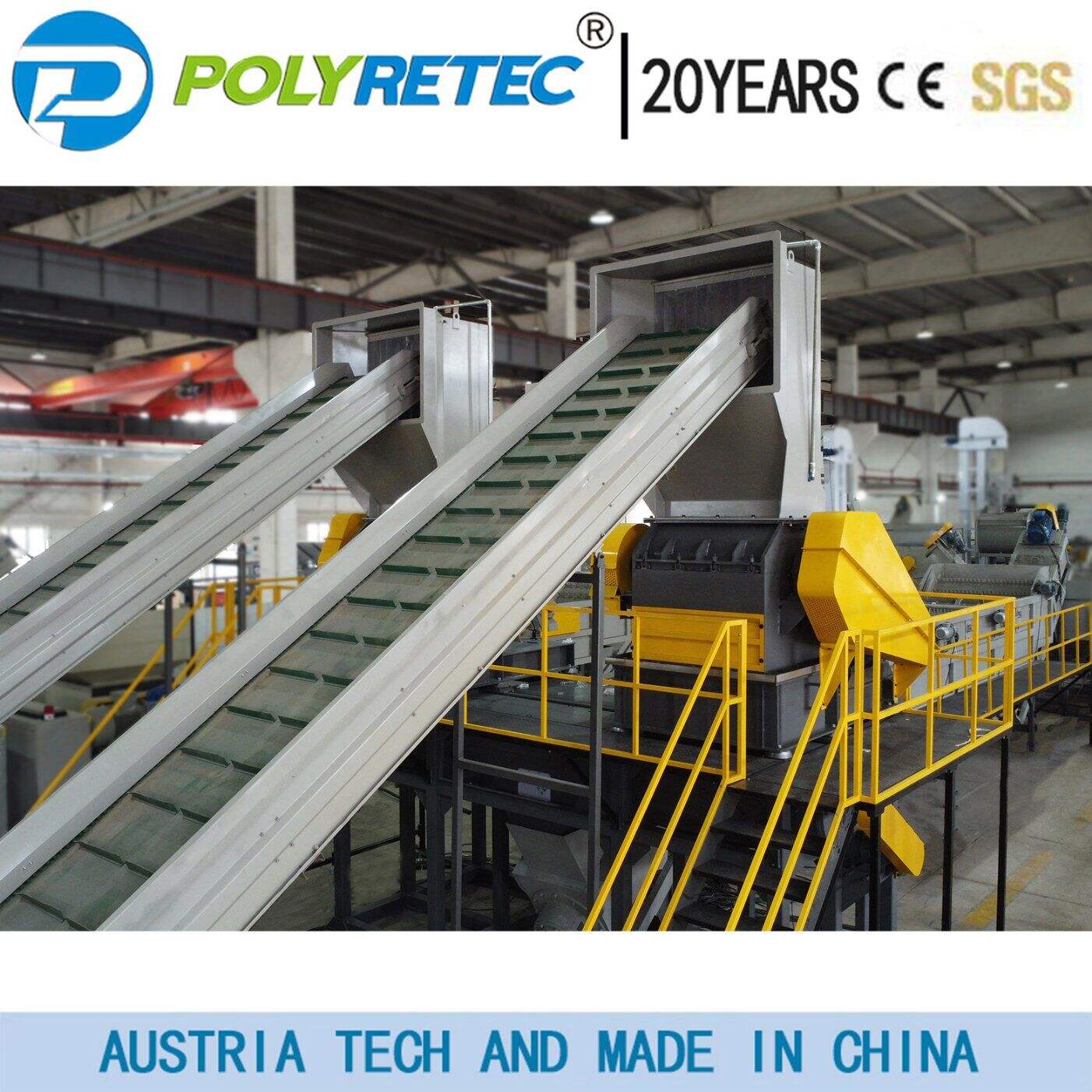

ldpe film recycling line

LDPE 필름 재활용 라인은 저밀도 폴리에틸렌(LDPE) 필름 폐기물을 처리하여 귀중한 재생 소재로 전환할 수 있는 첨단 솔루션을 제공합니다. 이 포괄적인 시스템은 여러 단계의 처리 과정으로 구성되어 있으며, 강력한 분쇄 장치를 통해 플라스틱 필름 폐기물을 관리 가능한 크기로 줄이는 과정부터 시작됩니다. 라인에는 재료에서 오염물질, 먼지 및 접착제 잔여물을 효과적으로 제거하는 고급 세척 시스템이 탑재되어 있습니다. 세척 단계 이후에는 고효율 원심력 및 열풍 방식을 사용하는 고도화된 건조 공정을 통해 재료를 건조합니다. 시스템의 핵심은 펠릿화 장치에 있으며, 여기서 처리된 재료를 용융, 필터링하여 고품질의 재생 펠릿으로 전환시킵니다. 라인은 자동 제어 시스템을 갖추고 있어 일관된 운전 파라미터와 제품 품질을 유지하도록 설계되었습니다. 시간당 300~1000kg의 처리 능력을 갖춘 이 시스템은 농업용 필름, 포장재, 쇼핑백 등 다양한 종류의 LDPE 필름 폐기물을 처리할 수 있습니다. 전체 공정은 에너지 소비를 최소화하면서도 생산 품질을 극대화하도록 설계되어 있어 플라스틱 재활용 작업을 위한 환경적으로 책임감 있고 경제적으로 실현 가능한 솔루션을 제공합니다.