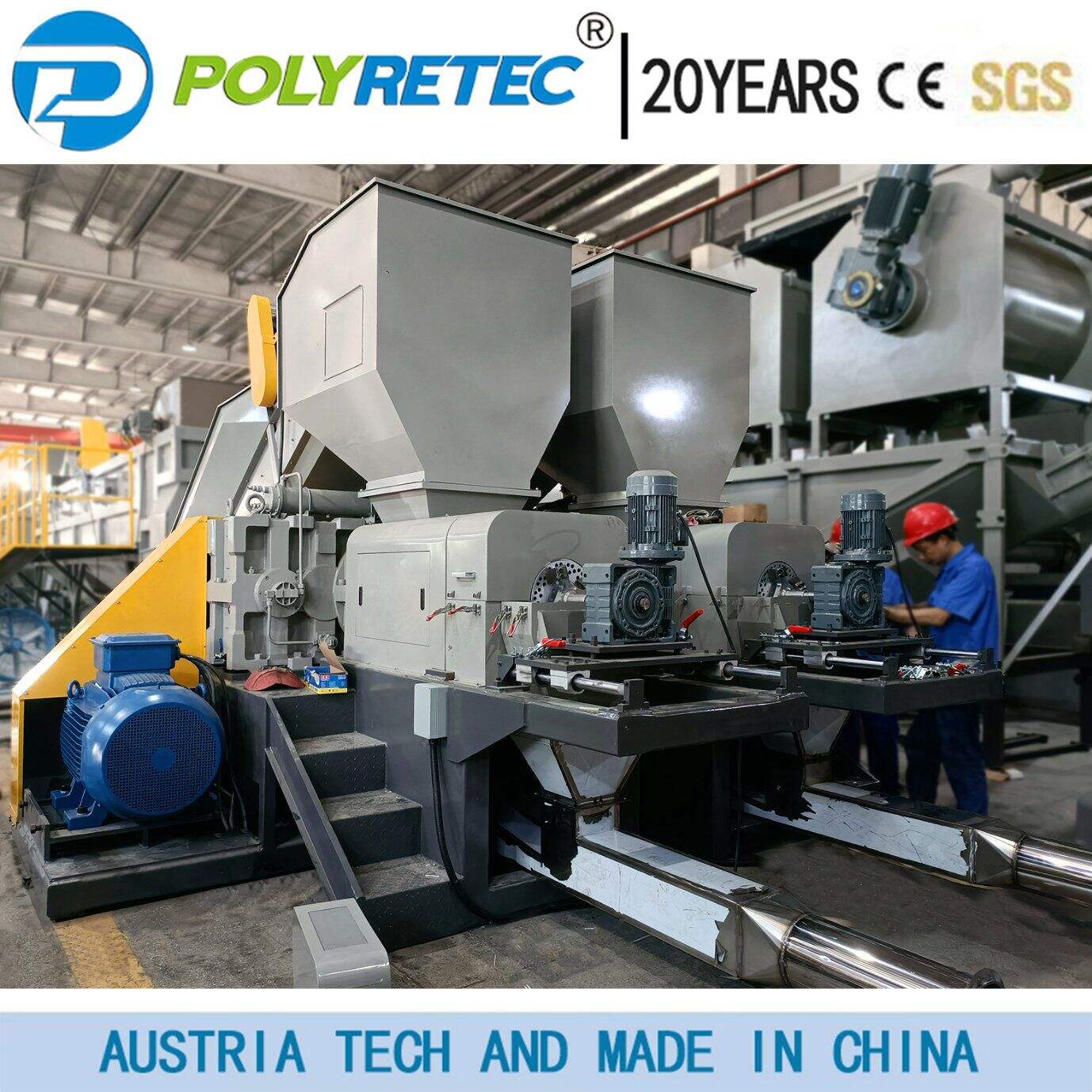

plastic crusher machine manufacturers

Plastic crusher machine manufacturers represent a vital segment of the recycling industry, specializing in the design and production of essential equipment for plastic waste reduction. These manufacturers develop sophisticated machines that efficiently transform various plastic materials into smaller, manageable pieces suitable for recycling or further processing. Their machines incorporate cutting-edge technology, featuring robust steel blades, precision-engineered rotors, and advanced control systems that ensure consistent particle size reduction. The equipment produced by these manufacturers typically includes various crushing mechanisms, from single-shaft to multi-shaft designs, capable of processing different types of plastics from PET bottles to industrial waste. Modern plastic crusher machines are equipped with safety features such as emergency stop systems, overload protection, and noise reduction technology. These manufacturers often provide customization options to meet specific industry requirements, whether for small-scale recycling operations or large industrial facilities. Their machines are designed with maintenance-friendly features, ensuring long-term reliability and optimal performance. Additionally, many manufacturers incorporate energy-efficient systems that reduce operational costs while maintaining high productivity levels.