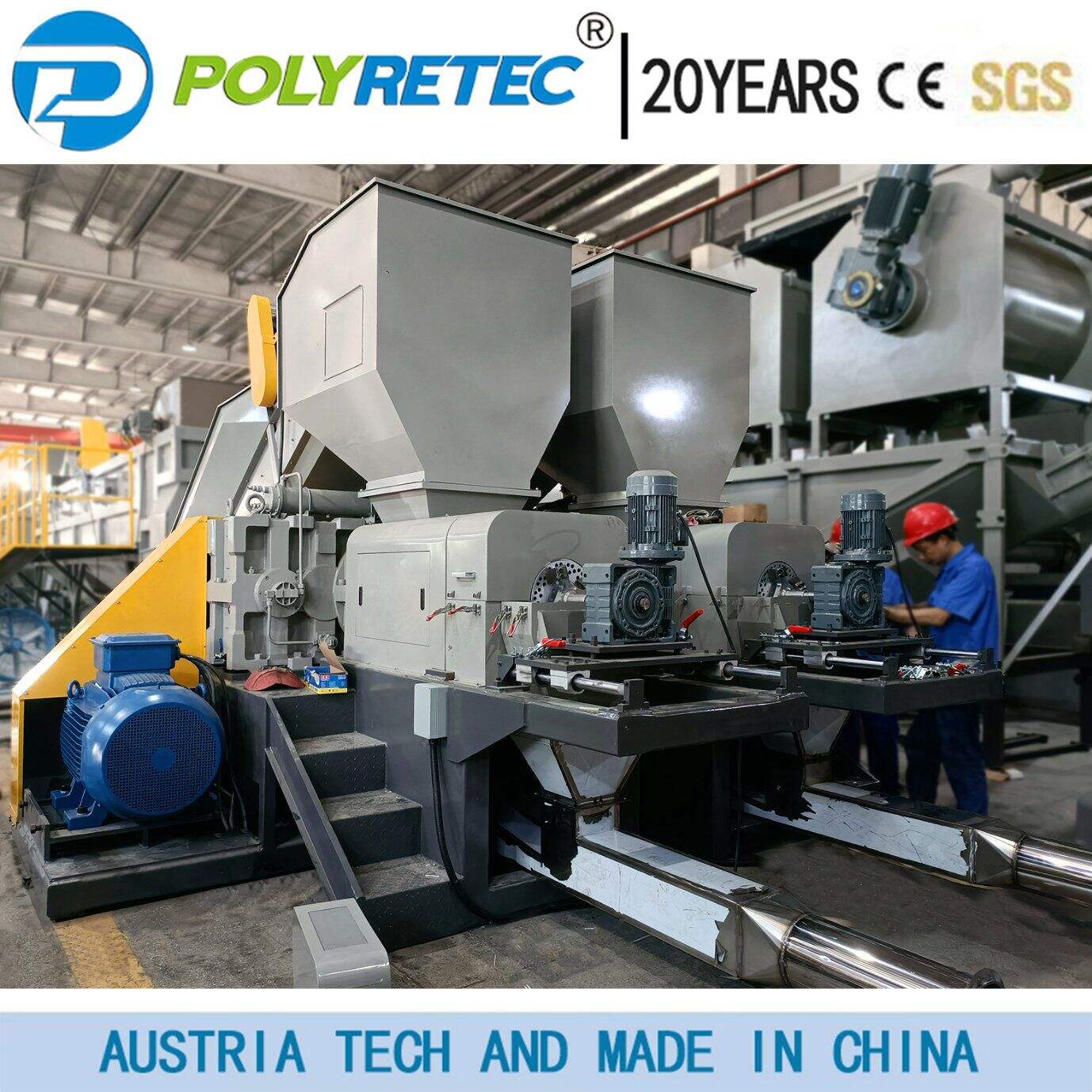

plastic granulator machine manufacturers

Plastic granulator machine manufacturers are industry leaders in developing and producing advanced recycling equipment essential for modern plastic processing operations. These manufacturers create robust machines designed to efficiently reduce plastic waste into uniform granules suitable for reuse in production. Their machines incorporate cutting-edge technology, featuring precision-engineered rotary blades, advanced screening systems, and automated feeding mechanisms that ensure consistent granule size and quality. The equipment typically includes hardened steel cutting chambers, variable speed controls, and sophisticated safety systems that meet international standards. These manufacturers focus on producing machines with different processing capacities, ranging from small units processing 50 kg/hour to industrial-scale systems handling several tons per hour. They emphasize energy efficiency, noise reduction, and durability in their designs, often incorporating smart controls for optimal performance monitoring. Many manufacturers also provide customization options to meet specific client requirements, whether for general plastic recycling or specialized applications in industries such as automotive, packaging, or construction. Their commitment to innovation is evident in the integration of features like automatic blade sharpening systems and advanced material separation capabilities.