מחיר מכונת מחזור פלסטיק

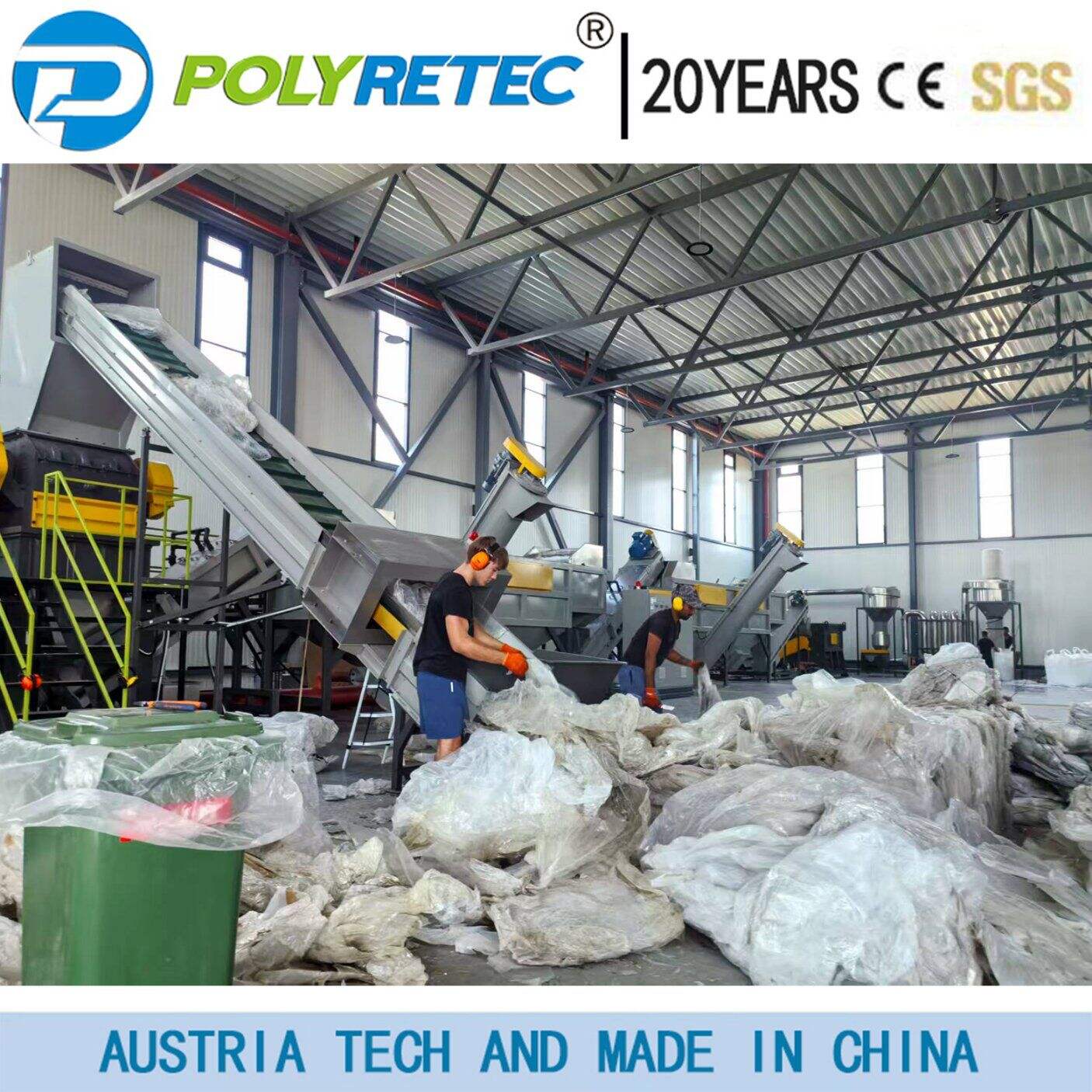

המחיר של מכונות 재ציקל פלסטיק משתנה במידה רבה בהתאם لقدرات, הקיבולת והמאפיינים הטכנולוגיים שלהן. מכונות בסיסיות נעות בדרך כלל בין 10,000 ל-30,000 דולר, ומותאמות לתפעול בקנה מידה קטן. יחידות תעשייה ממוצעות עולות בין 50,000 ל-150,000 דולר, ומציעות יכולות עיבוד מתקדמות יותר ותכונות אוטומציה. מערכות מתקדמות עולות על 300,000 דולר, וכוללות מנגני מיון מתקדמים, מספר שלבי עיבוד, ומערכות שליטה מתקדמות. מכונות אלו מפנות ביעילות מגוון חומרי פסולת פלסטיק לחומר גלם ניתן לשימוש חוזר, כמו פלטlets (гранולות) או פלורידים (שבבי פלסטיק), באמצעות תהליכי מיון, טחינה, שטיפה, ייבוש ופלטטיזציה. מכונות 재ציקל פלסטיק מודרניות מצוידות במערכות הזנה אוטומטיות, שליטה מדויקת בטמפרטורה, ויכולות מיון מתקדמות המשתמשות בсенסורים אופטיים. הן מסוגלות לעבד סוגי פלסטיק שונים, בהם PET, HDPE, LDPE ו-PP, עם קיבולת ייצור הנעה בין 100 ק"ג לשעה ועד מספר טונות בשעה. תקופת ההחזר על ההשקעה נעה בדרך כלל בין 12-24 חודשים, תלוי בגודל התפעול ובתנאי השוק. דגמים מתקדמים כוללים מנועים חוסכי אנרגיה, מערכות מחזור מים, ומנגני שליטה באיכות שמבטיחים תוצאות אחידות.