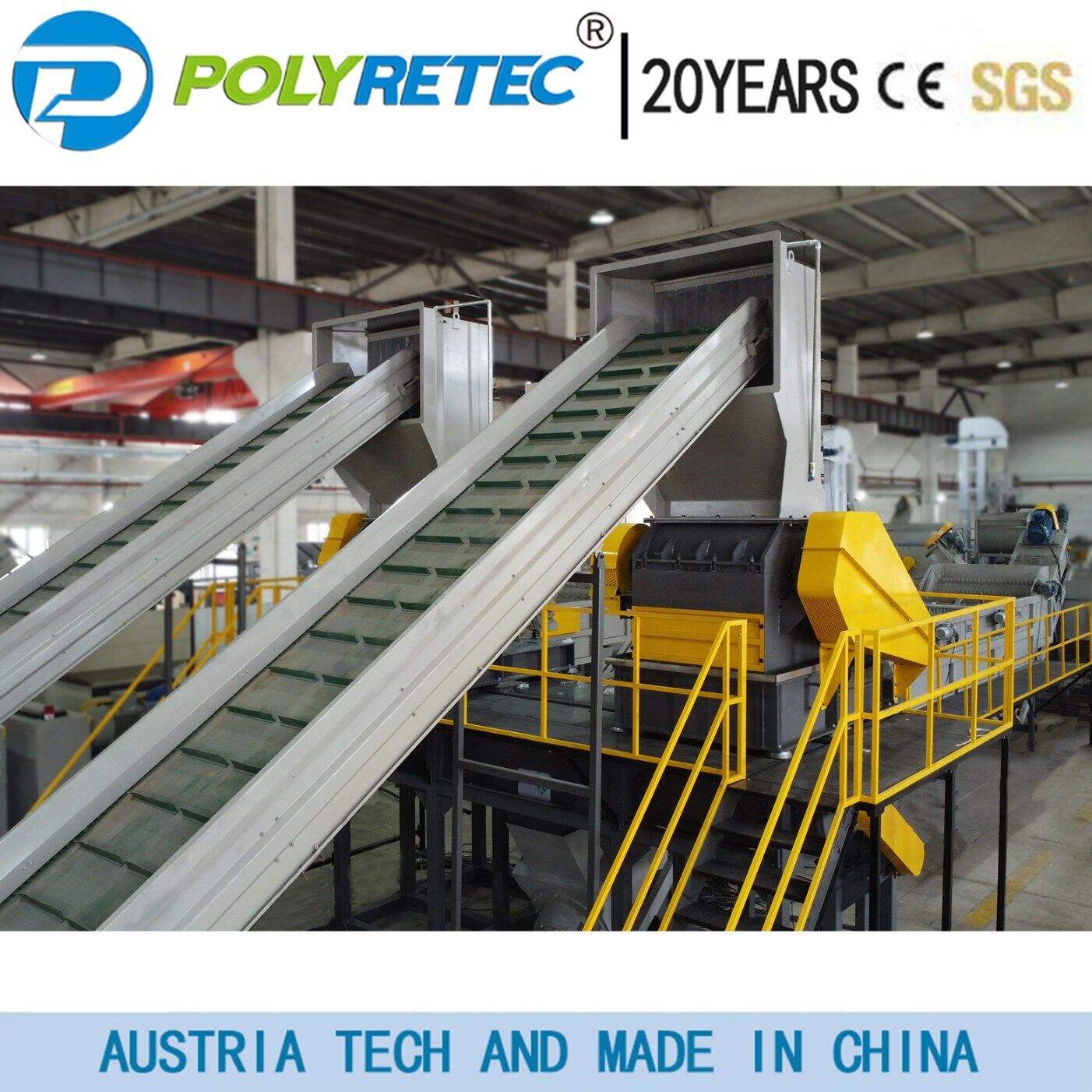

מקשה לריסוק פלסטיק

מקשה לייצור פלסטיק מוחזר היא מכונה תעשייתית מתקדמת שפותחה כדי לעבד ולצמצם באופן יעיל מגוון סוגי פסולת פלסטיק לבלוקים צפופים וקלים لإدارة. ציוד חדשני זה משלב מערכות הידראוליות עוצמתיות עם מנגנונים של שליטה מדויקת כדי להפחית את נפח הפסולת הפלסטיקית ב-90%. המכונה מצוידת תא לחיצה עוצמתי עם לוחות פליז מוגזים ומנוף הידראולי בלחץ גבוה שמפעיל כוח רב כדי לאפס את החומרים. מקשות מודרניות לייצור פלסטיק מוחזר כוללות טכנולוגיית חיישנים חכמה המותאמת אוטומטית את כוח הלחיצה בהתאם לצפיפות וenz volum של החומר. לרוב, המכונות מעבדות מספר סוגים של פלסטיק, בהם PET, HDPE, LDPE ו-PP, מה שהופך אותן לפתרונות גמישים ליישומים שונים בתהליכי מחזור. מערכת האכלה אוטומטית של המקשה מספקת זרימה עקבית של חומרים, בעוד מנגנוני ביטחון מובנים מגנים על המפעילים במהלך הפעלה. דגמים מתקדמים מצוידים בלוחות שליטה ספרתיים המאפשרים הגדרות מדויקות של פרמטרי פעולה ומעקב בזמן אמת אחרי מחזורי לחיצה. בלוקי הפלסטיק המוחזקים הם בעלי יכולת איחסון ותחבורה קלה, מה שמצמצם משמעותית את דרישות האחסון והעלויות התחבורתיות. מכשורים אלו הם חיוניים במתקני מחזור, מפעלים לייצור ומרכזי ניהול פסולת, ותורמים לנהלי ניהול פסולת פלסטיק ברת-קיימא.