| Feeding size | 460*400mm |

| Screw diameter | φ80mm |

| Screw speed | 100r/min |

| Heating power | 2.7kw |

| Main Motor power | 5.5kw |

| Crusher motor power | 3kw |

| Crusher blades quantity | 7sets |

| Machine weight | 580kg |

Feeding size |

650*400mm |

900*600mm |

1000*900mm |

Screw diameter |

φ138 mm |

φ190-120 mm |

φ190-120 mm |

Screw speed |

165 r/min |

110 r/min |

150 r/min |

Heating power |

3kw |

10kw |

10kw |

Main Motor power |

7.5kw |

15kw |

22KW |

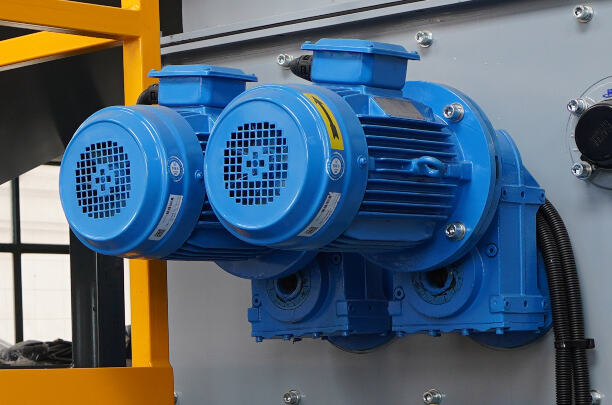

Crusher motor power |

3kw |

3kw*2sets |

3kw*4sets |

Crusher blades quantity |

8sets |

8+9sets |

10+11+10+11sets |

Machine weight |

900 Kg |

1500kg |

2200kg |