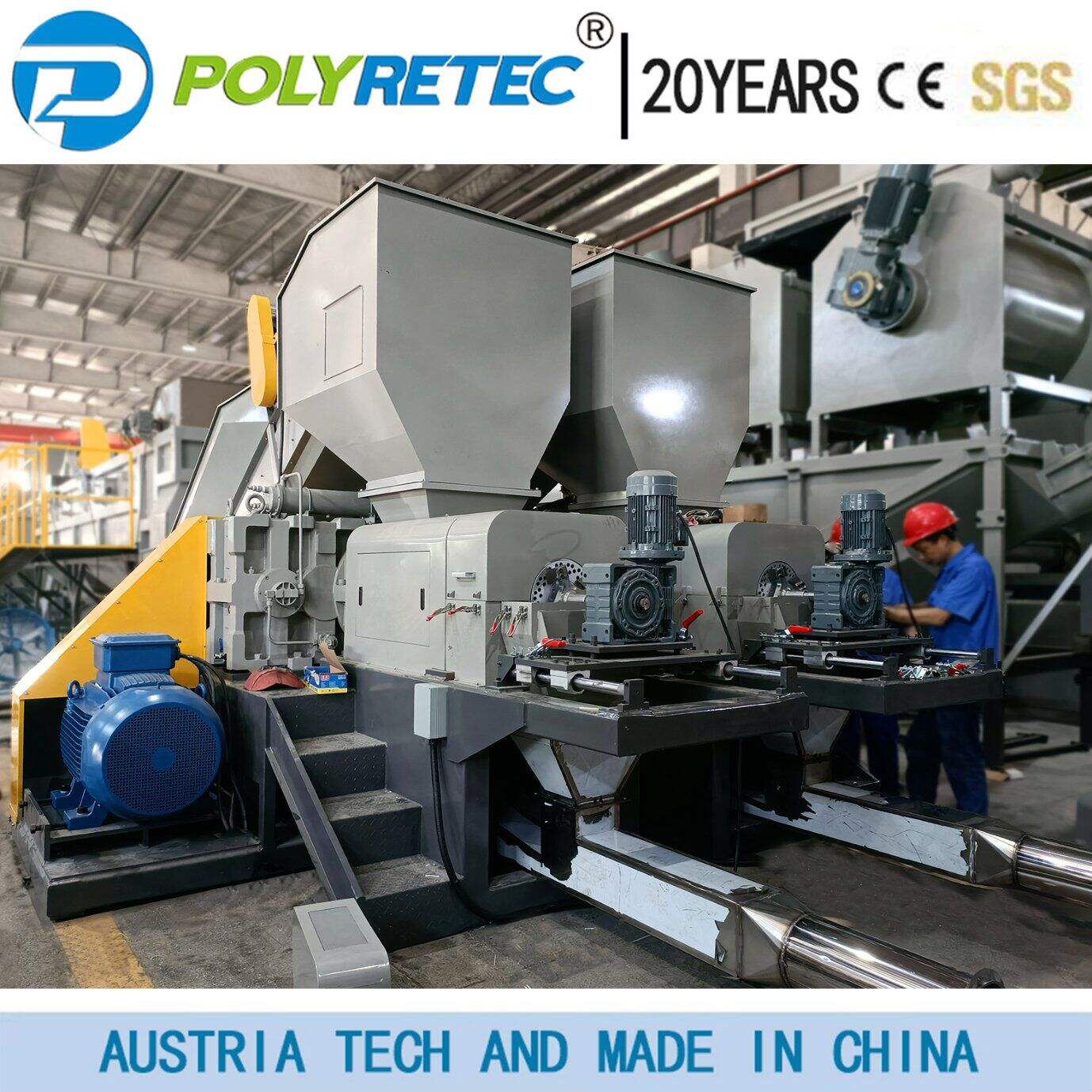

waste plastic recycling machine price

The waste plastic recycling machine price represents a significant consideration for businesses looking to invest in sustainable waste management solutions. These machines, available across various price points from $10,000 to $100,000, offer comprehensive solutions for processing different types of plastic waste. The equipment typically includes multiple components such as washing systems, crushing units, melting chambers, and pelletizing mechanisms, all working together to transform waste plastic into reusable materials. Modern machines incorporate advanced sorting technologies, automated feeding systems, and precise temperature control mechanisms to ensure optimal processing efficiency. The price varies depending on factors such as processing capacity, ranging from 100 kg to 3000 kg per hour, automation level, and additional features like integrated quality control systems. These machines can process various plastic types including PE, PP, PVC, and PET, making them versatile investments for recycling facilities. The technology employed ensures minimal energy consumption while maintaining high output quality, making it a cost-effective solution for long-term operation.