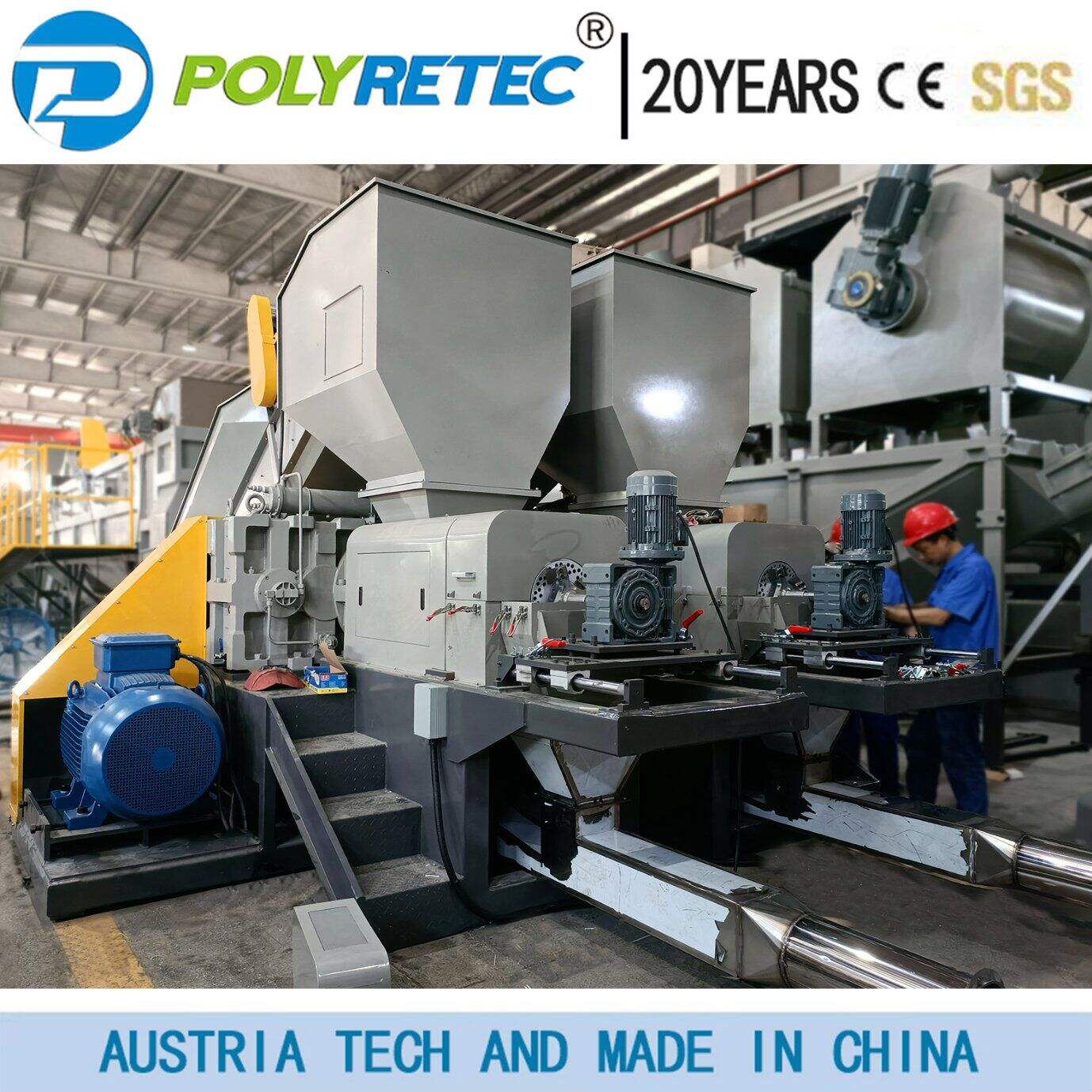

plastic waste recycling machine price

The plastic waste recycling machine price represents a significant investment consideration for businesses looking to enter the recycling industry. These machines, available across various price points from $10,000 to $100,000, offer comprehensive solutions for processing different types of plastic waste. The price varies based on capacity, ranging from 100kg to 3000kg per hour, and technological sophistication. Modern units feature advanced sorting mechanisms, cleaning systems, and precise temperature control for optimal melting and reformation processes. The machines incorporate multiple stages including sorting, crushing, washing, drying, and pelletizing, ensuring a complete recycling solution. Key technological features include automated material detection systems, energy-efficient motors, and precision control panels for monitoring all operational parameters. These machines can process various plastic types including PET, HDPE, LDPE, and PP, making them versatile for different recycling needs. The price also factors in additional features such as noise reduction technology, safety mechanisms, and quality control systems that ensure consistent output quality.