펫 병 세척 및 재활용 기계

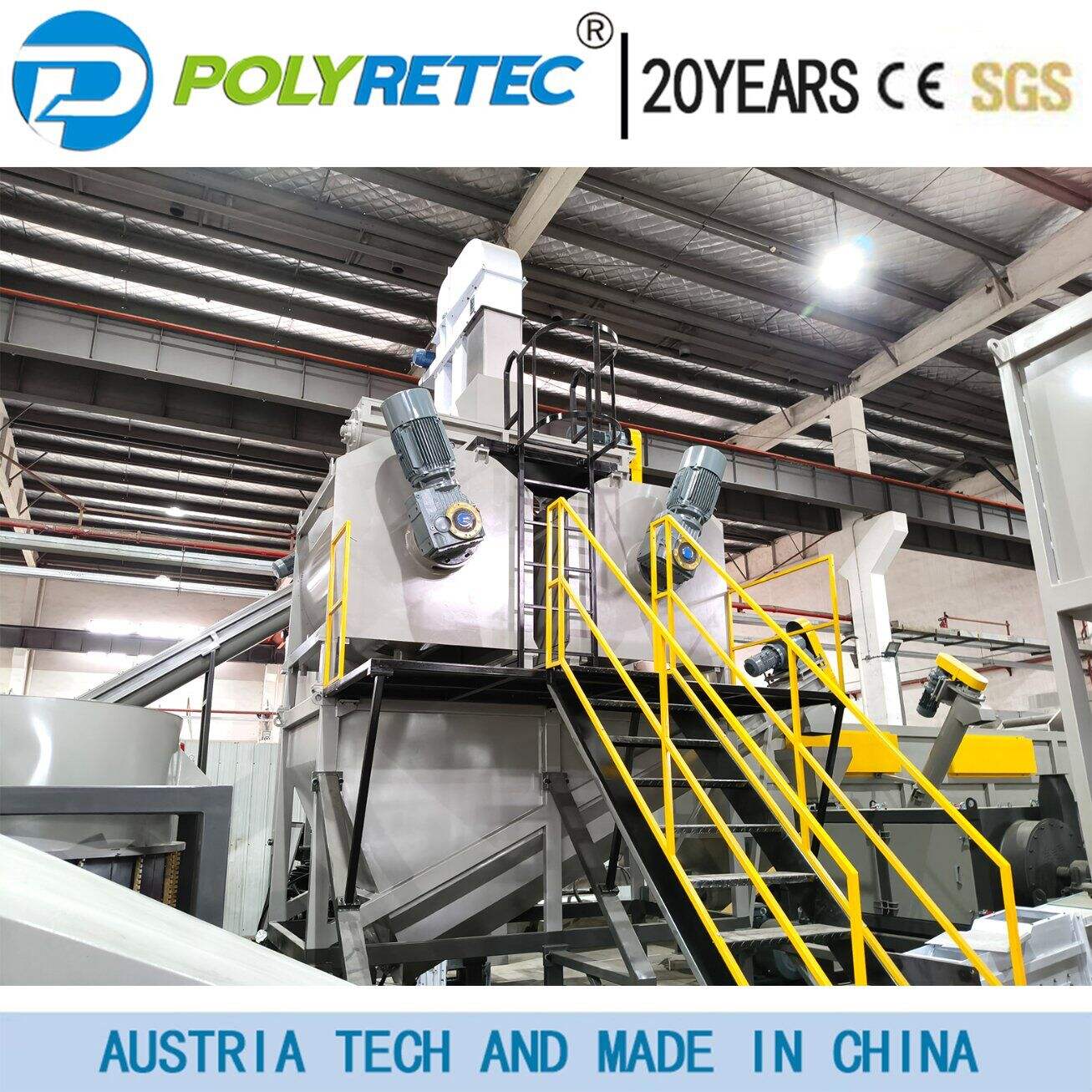

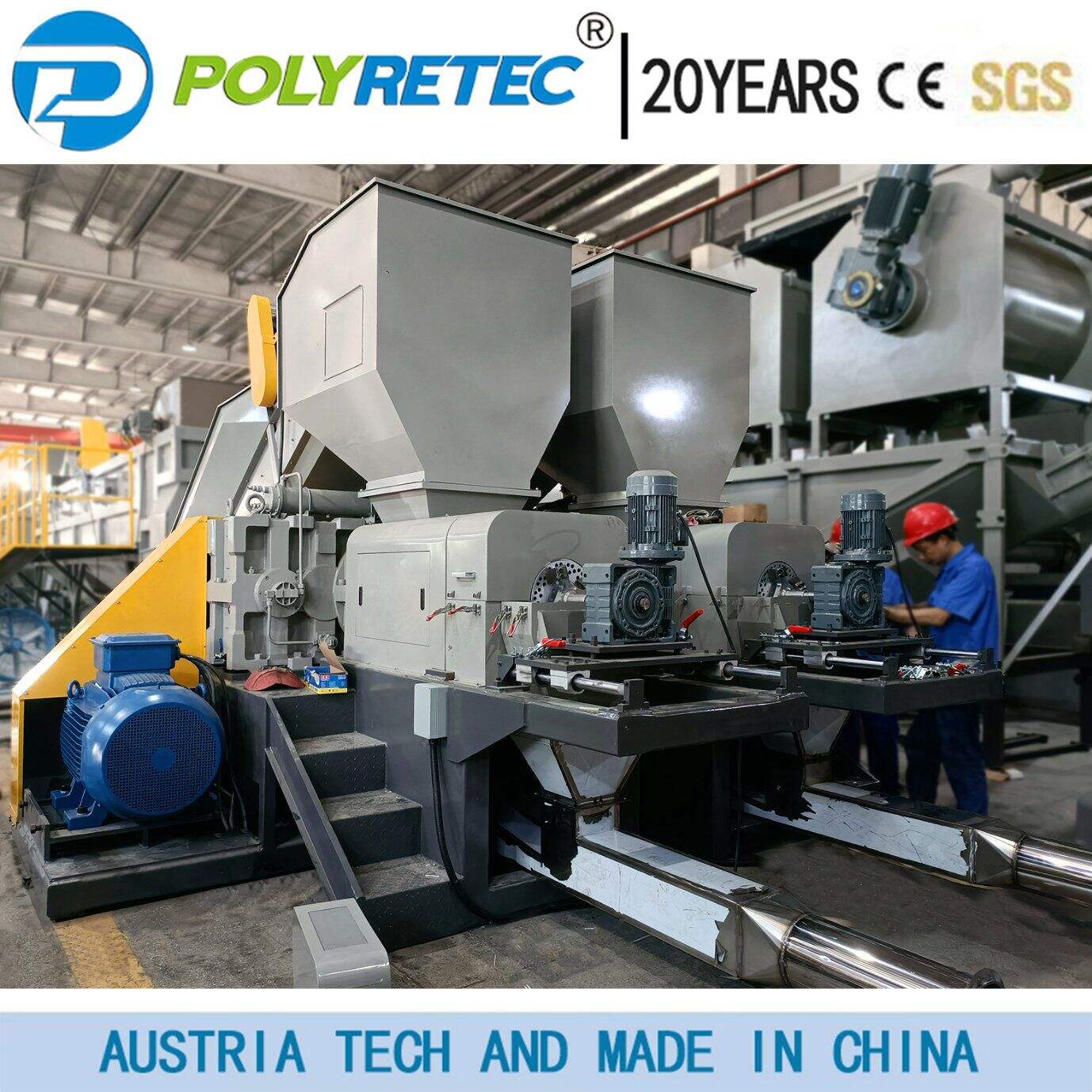

PET병 세척 재활용 기계는 플라스틱 병을 효율적이고 지속 가능하게 가공 및 재활용할 수 있는 최첨단 솔루션입니다. 이 첨단 시스템은 여러 단계의 세척 및 가공 과정을 포함하며, 먼저 정교한 분류 장치를 통해 PET병을 다른 재질과 분리하는 과정부터 시작됩니다. 이 기계는 병을 최적의 크기로 분쇄하는 고용량 크러셔 유닛을 갖추고 있으며, 이어서 라벨과 마개, 초기 오염물질을 제거하는 철저한 사전 세척 단계가 뒤따릅니다. 핵심 세척 공정에서는 특수 세제와 온수 처리 시스템을 활용하여 접착제와 기름, 그 밖의 불순물까지 완전히 제거합니다. 고급 마찰 세척 기술과 고속 원심 분리 방식을 결합해 뛰어난 세척 효과를 달성합니다. 시스템은 잔류 세제 성분까지 제거하기 위해 신선한 물을 사용한 여러 단계의 헹굼 공정도 포함합니다. 이후 청정 플레이크를 처리하기 위해 최첨단 건조 시스템이 작동하며, 이를 품질 검사 및 포장 작업에 바로 투입할 수 있도록 준비합니다. 전체 공정은 자동화되어 있으며, 지능형 제어 시스템을 통해 수자원과 에너지 소비를 최적화하면서도 일관된 품질의 출력을 유지하도록 모니터링됩니다.