ozean-Kunststoffrecycelmaschine

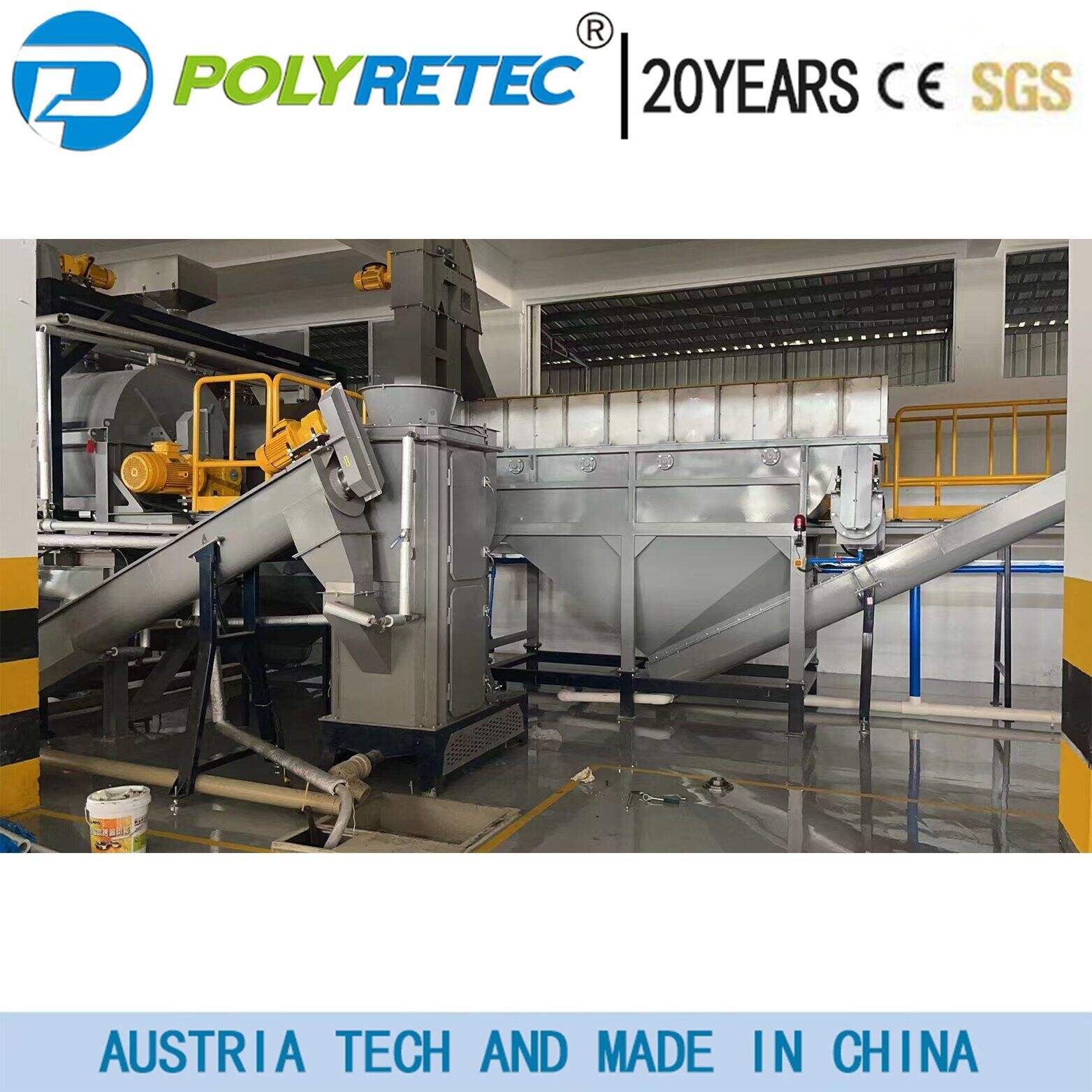

Die Ozean-Plastik-Recycling-Maschine stellt eine bahnbrechende Lösung im maritimen Umweltschutz dar. Sie wurde entwickelt, um effizient Plastikmüll aus marinen Umgebungen zu sammeln und aufzubereiten. Dieses innovative System kombiniert fortschrittliche Filtrationstechnologie mit leistungsstarken Verarbeitungsfunktionen und ermöglicht so die Umwandlung von Meeresplastik in wiederverwendbare Materialien. Die Maschine arbeitet nach einem Dreistufen-Prozess: Sammlung, Sortierung und Verarbeitung. Während der Sammlungsphase setzt das System spezielle Netze und Fördermechanismen ein, um schwimmende Plastiktrümmern aus verschiedenen Wassertiefen einzusammeln. In der Sortierphase kommen optische Sensoren mit KI-Unterstützung sowie mechanische Trenner zum Einsatz, um die Kunststoffe nach Art und Größe zu kategorisieren und somit eine optimale Verarbeitungseffizienz sicherzustellen. In der letzten Phase verarbeitet die Maschine das sortierte Plastik durch Reinigungs-, Zerkleinerungs- und Pelletierprozesse und wandelt den Abfall in wertvolles Recycling-Rohmaterial um. Das modulare Design des Systems erlaubt den Einsatz auf verschiedenen Bootsgrößen, von kleinen Booten bis hin zu großen Schiffen, wodurch es an unterschiedliche Einsatzbedingungen angepasst werden kann. Mit einer Verarbeitungskapazität von bis zu 5 Tonnen pro Tag leistet die Maschine einen bedeutenden Beitrag zur Meeresreinigung und schafft gleichzeitig nachhaltige Materialströme für die Industrie. Fortschrittliche Überwachungssysteme liefern Echtzeitdaten zu den gesammelten Mengen, der Verarbeitungseffizienz und der Materialqualität, sodass Betreiber die Leistung optimieren und die Umweltwirkung nachverfolgen können.