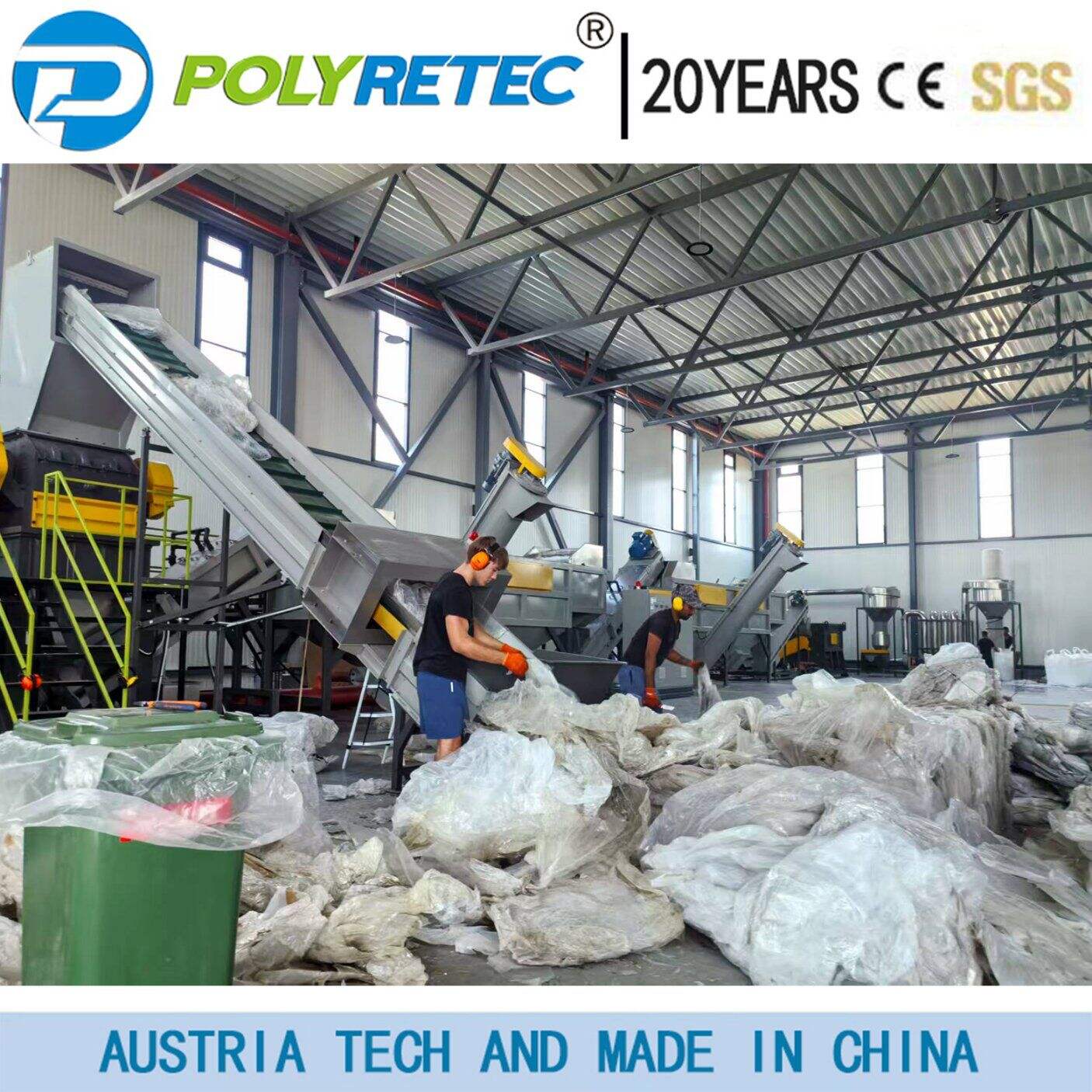

플라스틱 필름 재활용 세척기

플라스틱 필름 재활용 세척기는 폐기물 관리 기술 분야의 첨단 솔루션으로, 오염된 플라스틱 필름를 처리하고 세척하도록 특별히 설계되었습니다. 이 고도로 발전된 장비는 폐플라스틱 필름를 고품질의 재활용 가능한 소재로 전환하기 위해 여러 단계의 세척 공정을 결합합니다. 이 장비는 대형 오염물질을 제거하는 사전 세척 시스템, 소재를 철저히 세척하는 마찰 세척 장치, 최적의 청결도를 보장하는 고급 헹굼 시스템 등 일련의 특수 구성요소를 포함합니다. 이 기술은 고속 회전 메커니즘과 정밀 온도 조절을 적용하여 세척 효율성을 유지하면서 소재 손상을 방지합니다. 모듈식 설계로 인해 농업용 필름부터 포장재에 이르기까지 다양한 종류의 플라스틱 필름를 처리할 수 있으며, 오염 수준에 따라 매개변수를 조정할 수 있습니다. 시스템은 자동 제어 기능을 갖추고 있어 수질, 처리 속도, 소재 흐름을 모니터링하여 일관된 출력 품질을 보장합니다. 시간당 일반적으로 500~2000kg의 처리 능력을 갖춘 이 기계는 대량 처리를 효율적으로 수행하면서 통합된 재활용 시스템을 통해 물 절약 효과도 제공합니다. 최종적으로 깨끗하고 건조한 플라스틱 필름 플레이크를 생산하여 순환 경제 이니셔티브 및 지속 가능한 폐기물 관리 방식에 크게 기여합니다.