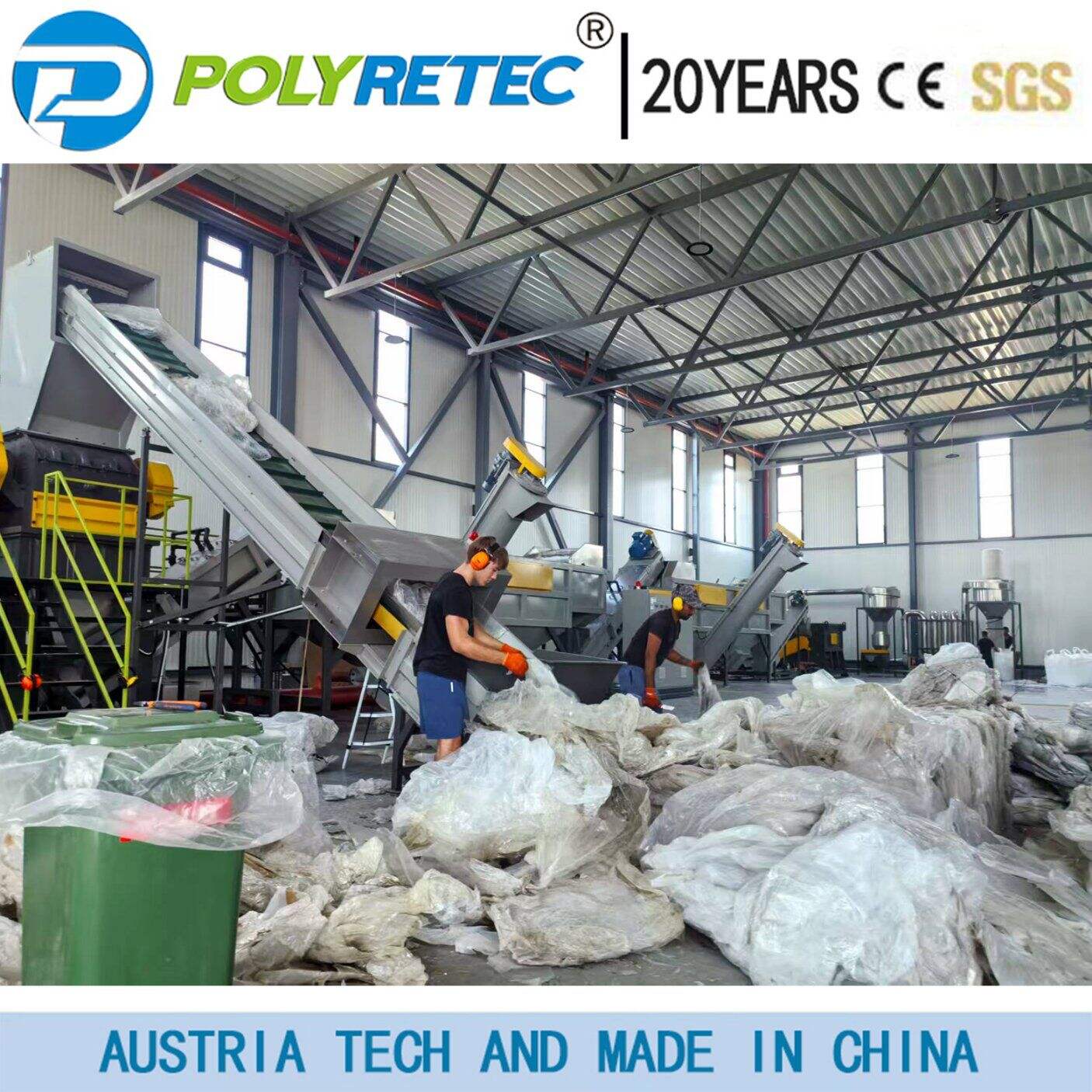

מכונה להחזרה של פלסטיק זבל

מכונת מיחזור פסולת פלסטיק מייצגת פתרון חדשני להפיכת פסולת פלסטיק למשאבים יקרי ערך. ציוד חדשני זה פועל באמצעות תהליך מקיף הכולל שלבי מיון, ריסוק, שטיפה, ייבוש ופלטיזציה. המכונה מעבדת ביעילות סוגים שונים של פלסטיק, כולל PET, HDPE, LDPE ו-PP, וממירה אותם לפלטות פלסטיק ממוחזרות באיכות גבוהה המתאימים לייצור מוצרים חדשים. מערכת האוטומציה המתקדמת שלה מבטיחה פעולה עקבית תוך מזעור התערבות אנושית, מה שהופך אותה לאידיאלית הן למתקני מיחזור קטנים והן ליישומים תעשייתיים בקנה מידה גדול. המכונה כוללת מנגנוני בקרת טמפרטורה מדויקים, מערכות חימום יעילות ועיצובי ברגים מתקדמים המבטיחים עיבוד חומרים אופטימלי. עם קיבולות עיבוד הנעות בין 100 ל-1000 ק"ג לשעה, ניתן להתאים אישית מכונות אלו כדי לעמוד בדרישות ייצור ספציפיות. המערכת משלבת טכנולוגיית סינון מתקדמת המסירה זיהומים ומזהמים, ומבטיחה שהתפוקה עומדת בתקני האיכות בתעשייה. בנוסף, העיצוב היעיל באנרגיה של המכונה מסייע בהפחתת עלויות תפעול תוך שמירה על רמות פרודוקטיביות גבוהות.