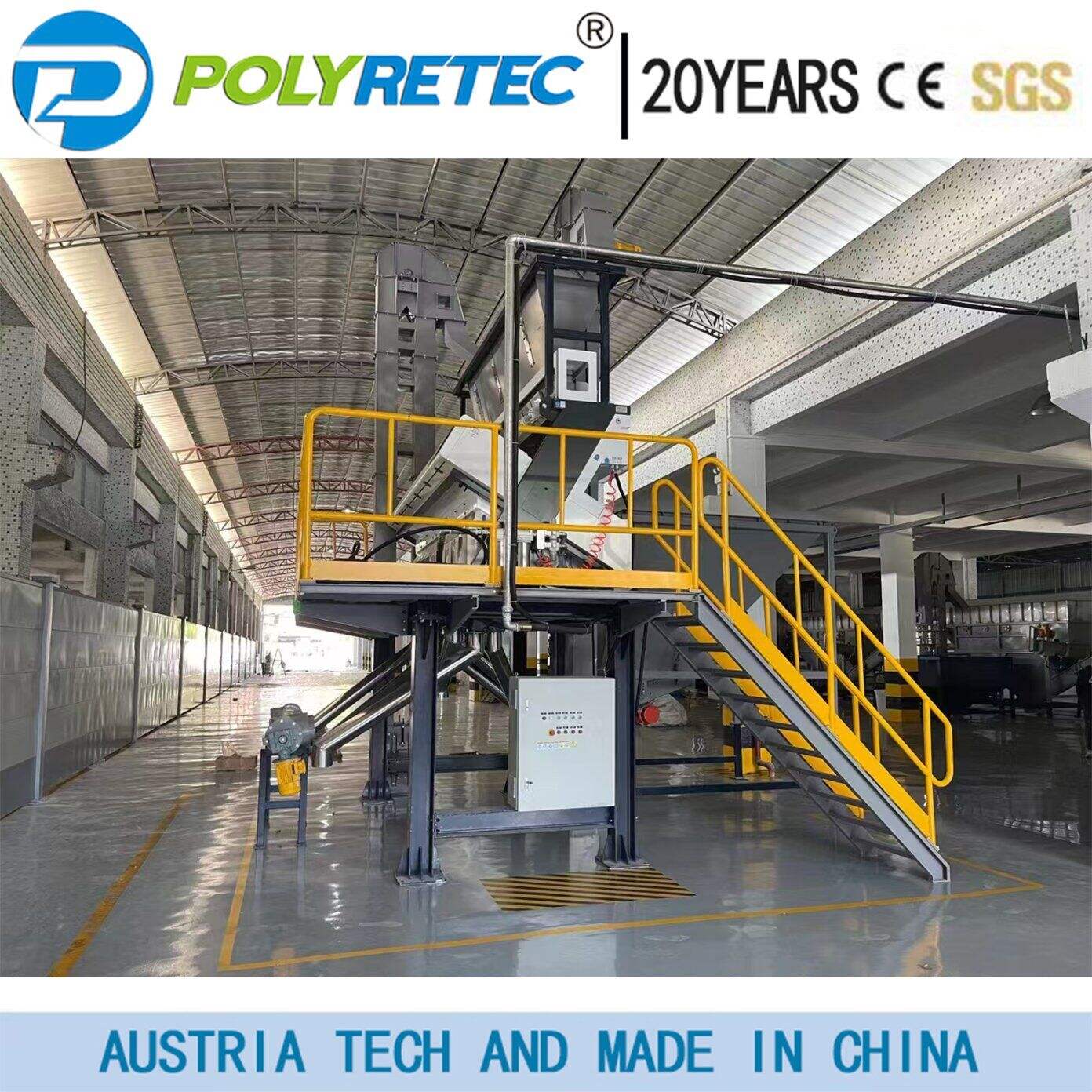

מפעל להטחת בקבוקי פלסטיק מיותרים

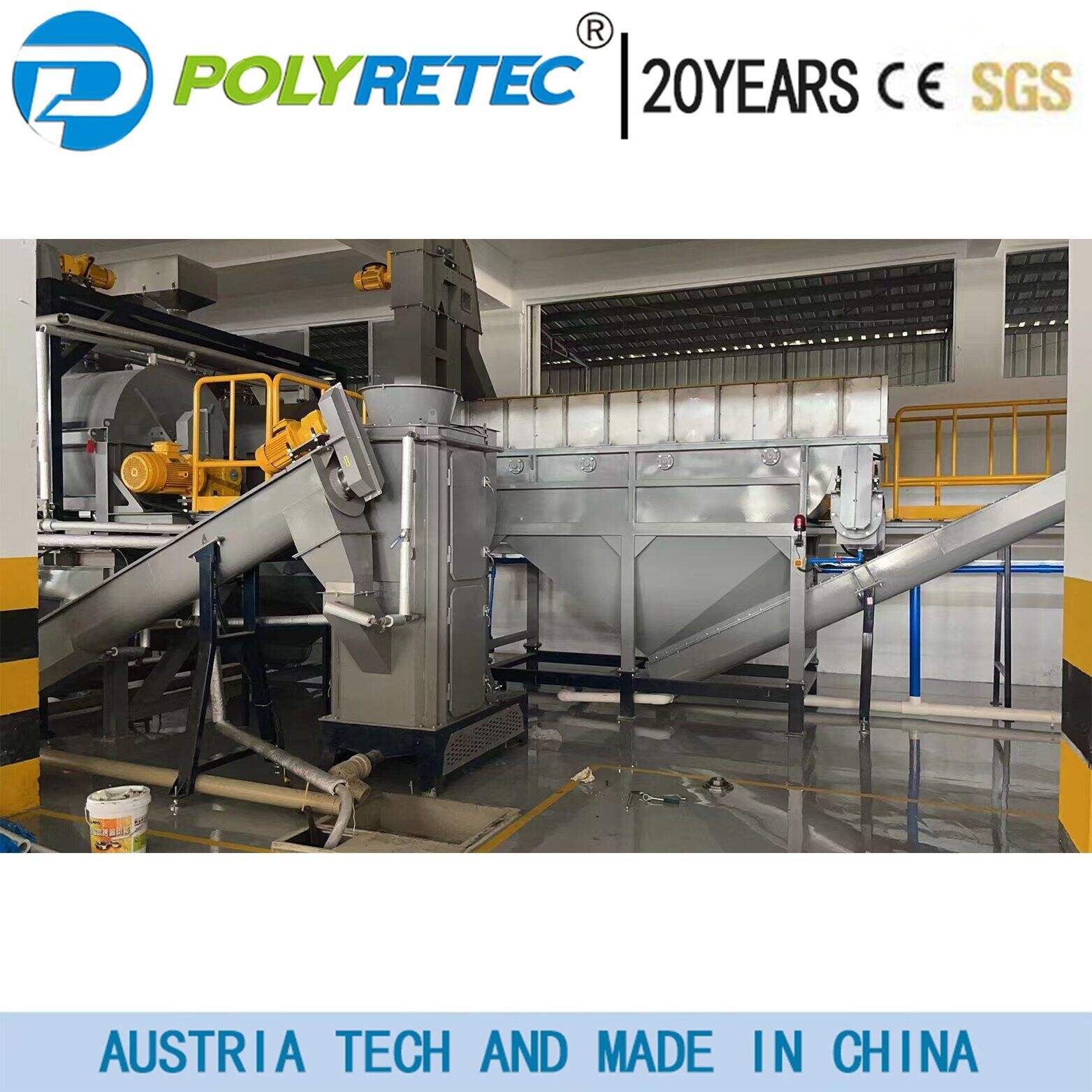

מפעל לריcycling של בקבוקי פלסטיק זבל מייצג פתרון חדשני לריפוי בקבוקי פלסטיק משומשים לחומרים ממוחזרים בעלי ערך. המפעל פועל באמצעות סדרה מורכבת של תהליכים, החל מנגנוני סיווג וניקוי המפרידים ביעילות בקבוקי PET מחומרים אחרים. מערכות ניקוי ושטוף מתקדמות מפרקות את הבקבוקים לחתיכות קטנות, ומסלקות מזהמים ותוויות. המתקן משתמש בטכנולוגיה של סיווג אופטי מדויק ביותר כדי להבטיח טוהר החומר, ולאחר מכן תהליך יבשה מיוחד המכין את הפשטידים לעיבוד נוסף. מערכת החץ של המפעל הופכת את הפליקים האלה לחלל פלסטיק ממוחזר באיכות גבוהה המתאים ליישומים שונים. עם מערכות בקרת אוטומטית ויכולות ניטור בזמן אמת, המפעל שומר על איכות תוצרת עקבית תוך אופטימיזציה של יעילות אנרגיה. המתקן יכול לעבד כמה טונות של בקבוקים פלסטיק בשעה, תורם באופן משמעותי להפחתת פסולת ולמאמצים לשימור הסביבה. צמחים מודרניים כוללים גם מערכות מיחזור מים ומנגנוני התאוששות אנרגיה, מה שהופך את כל התהליך לקיים מבחינת הסביבה.