מערכת 재활וץ של פלסטיק

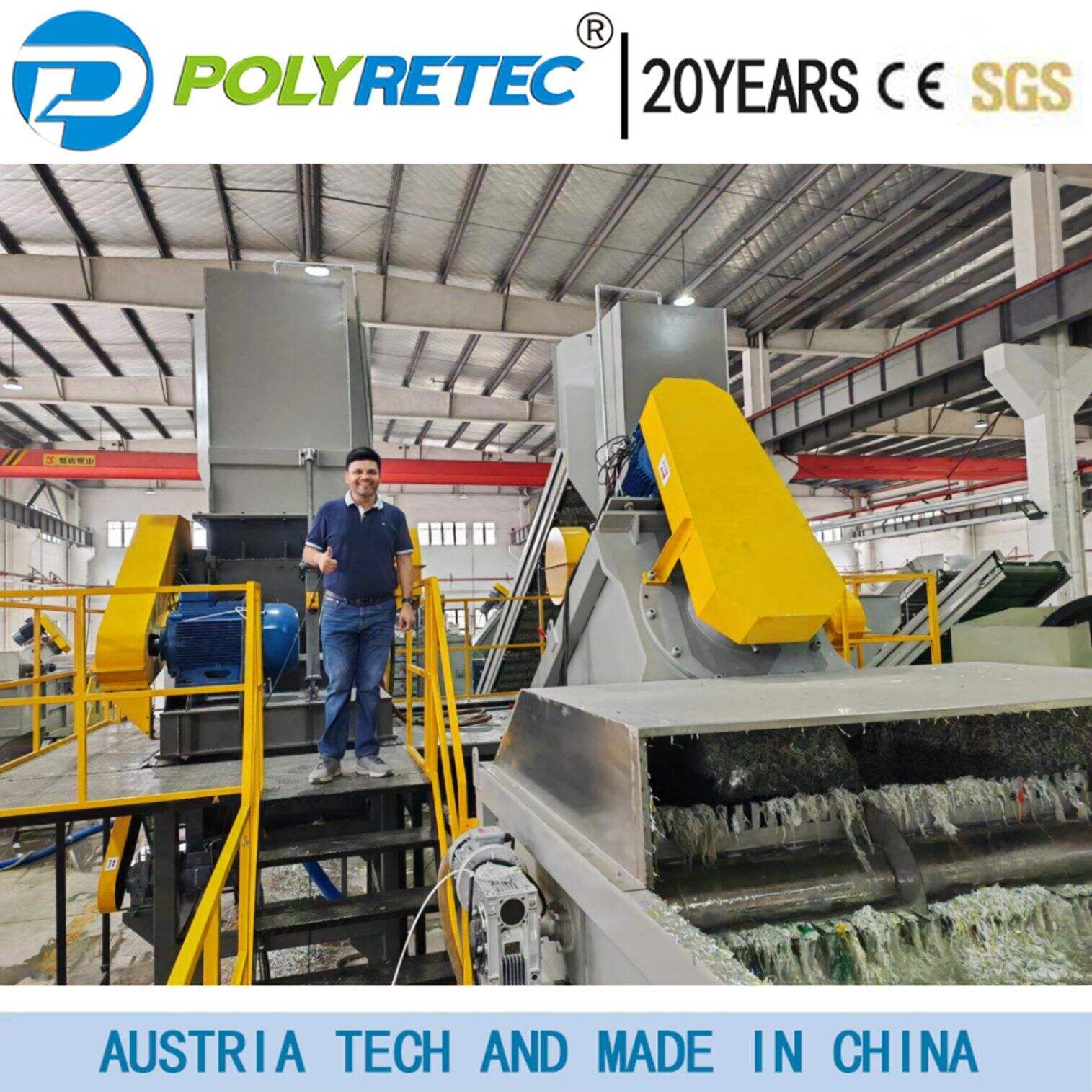

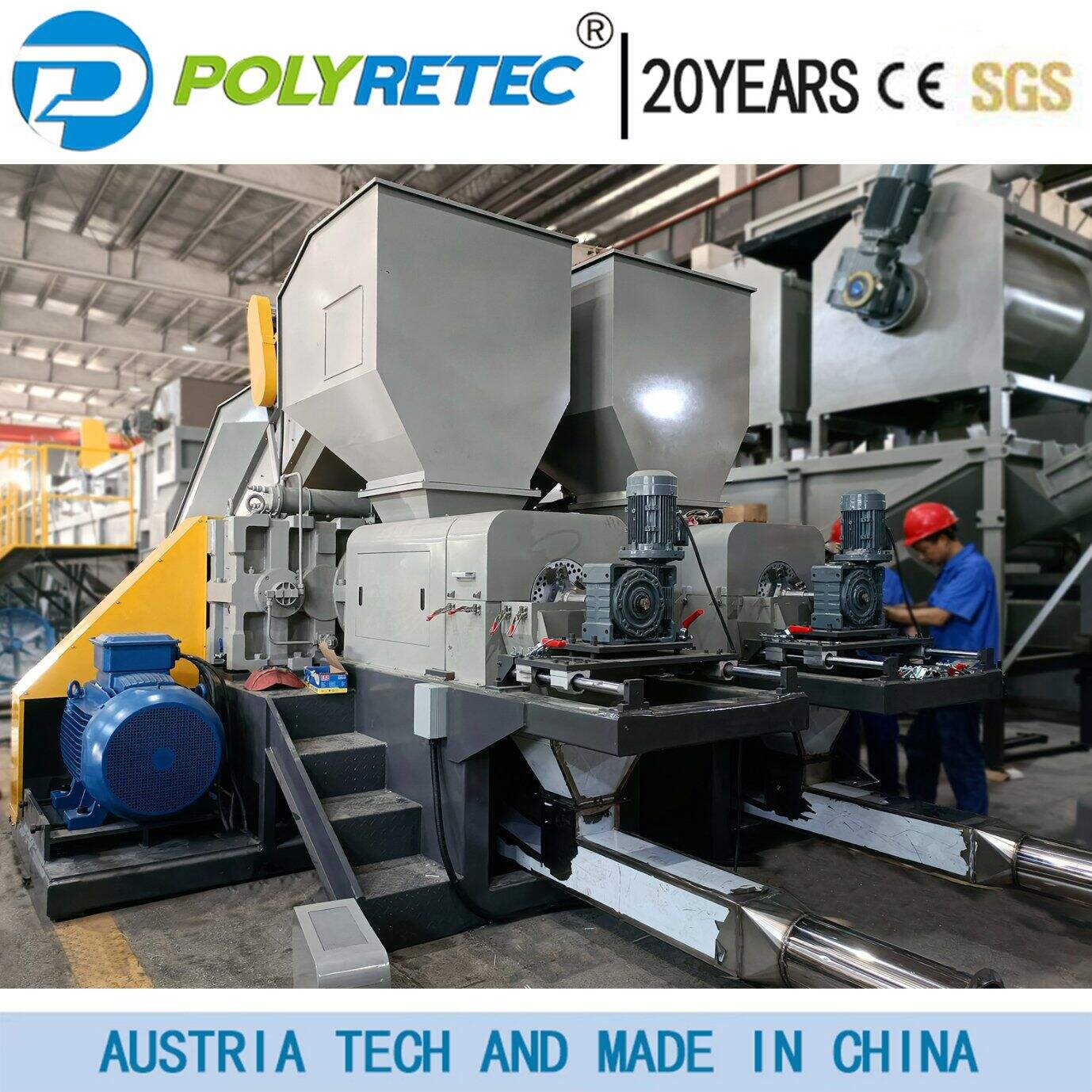

מערכת 재활וץ פלסטיק מייצגת פתרון כולל המתוכנן להפוך פלסטיק מוצק למשאבים בעלי ערך באמצעות סדרת תהליכים מתקדמים. המערכת כוללת מספר שלבים: מיון, ניקוי, קטעה, נמס ופלטניזציה, אשר מעובדים בצורה יעילה מגוון סוגי פלסטיק. טכנולוגיית חיישנים מתקדמת מאפשרת זיהוי והפרדה אוטומטית של סוגי פלסטיק שונים, תוך ביטחון יעילות מקסימלית בעיבוד. מנגנון הניקוי של המערכת מסיר מזהמים, תווית ודבקים באמצעות תהליכי ניקוי תחת לחץ גבוה וניקוי על ידי החיכוך. ציוד הקטעה המודרני מקטן פריטי פלסטיק לגודל אחיד, ומכך מקל על תהליך העיבוד בשלבים הבאים. שלב הנמס משתמש במערכות שליטה מדויקות בטמפרטורה כדי להפוך את הפלסטיק המעובד למצב נוזלי, תוך שמירה על שלמות החומר. לבסוף, שלב הפלטניזציה ממיר את הפלסטיק הנמס לפלטlets אחידים המתאימים לייצור מוצרים חדשים. המערכת המשולבת מסוגלת לעבד מגוון סוגי פלסטיק, בהם PET, HDPE, LDPE ו-PP, מה שעושה אותה גמישה ליישומים שונים של 재활וץ. העיצוב המודולרי של המערכת מאפשר הרחבה והתאמה על פי דרישות עיבוד ספציפיות, בעוד מערכות המניטורינג המתקדמות מבטיחות יציבות באיכות היציאה.